OK now I unnerstaan!

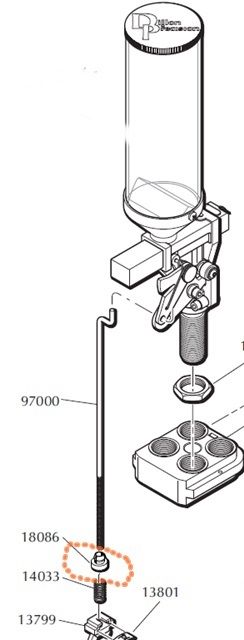

It actually starts by setting up the 13799/13801 "

stripper wing nut" correctly for the individual die set.

Dillon's instructions aren't quite right, you need more tension than they say for reliable operation of the slide. I set it as they say initially, with the bushing just making contact. But then I

tune it for full front to rear movement of the powder bar. (It seems to be about 1 1/2 to 2 turns tighter).

To remove it (like changing calibers) I just pull the main handle forward a little, so that the 13885 "

return bracket" lifts the bushing away from the spring enough to clear the cutout. Then I push down on the rim of the bushing & it pops free of the cutout. Then I just swing the rod out of the way & lower the ram to "rest". To re insert it I swap the heads & again pull the handle forward slightly then slip the bushing under the cutout & let the ram down. It usually seats itself.

I actually discovered that I have 2 different bushings on my rods!

There's the older (original?) one which is black colored & has a very slight "barrel", probably only 1/8" or so. & then there's a "newer" one on the rod I ordered that is white plastic & has a much longer barrel, probably a good 1/4" or so! You'll need to clear the barrel section to let the actual rod pass through the cut so your movement may be greater than mine to clear the extra length.

You'll have to re-do the adjustment for tension every time you change the setups. I got lazy & ordered a couple of spare rods, one for each setup!