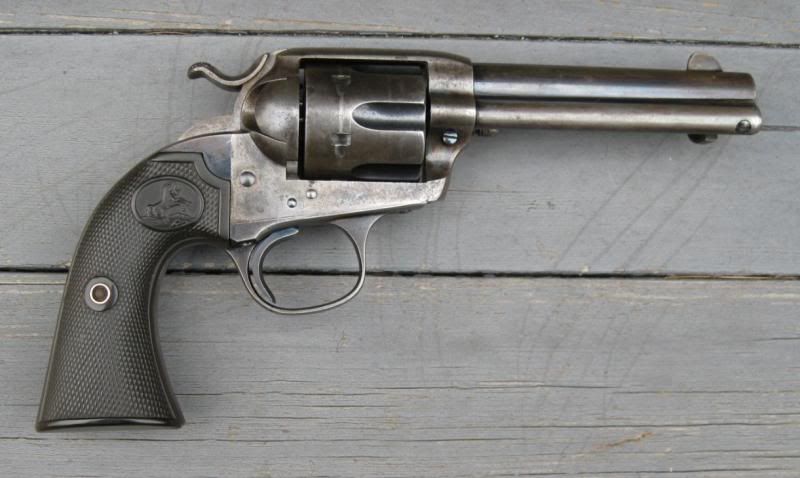

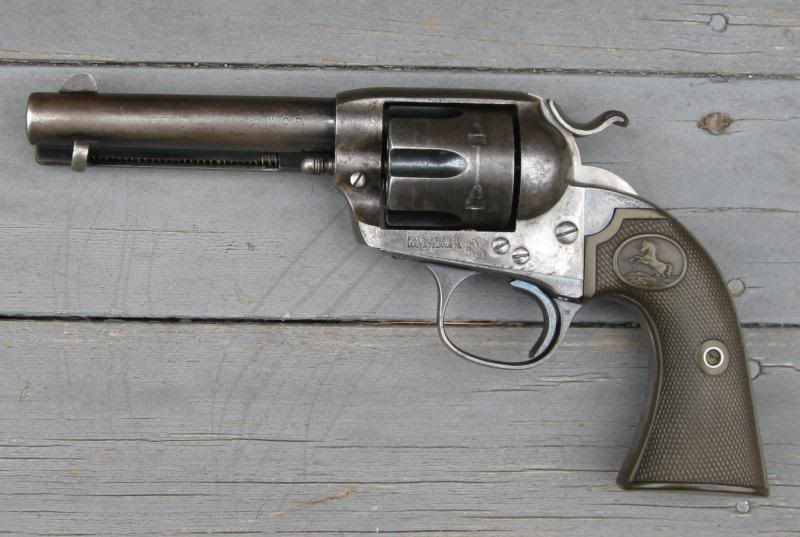

I have looked at pictures of many fine specimens of Colt antique guns. I have found basically two types of finish. One is a semi-matte black which can be shiny depending how the metal was polished. I also see a stark bluish-grey color on some barrels. Even though probably wood charcoal, bone, and other ingredients are probably involved with both results, there are evidentally two different techniques involved. BTW I find the barrels with the blue color to be very rare.

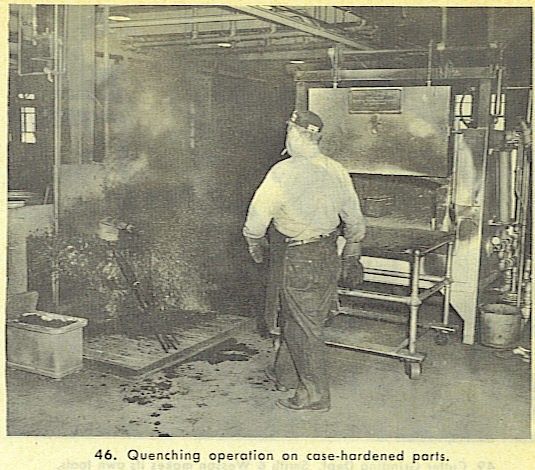

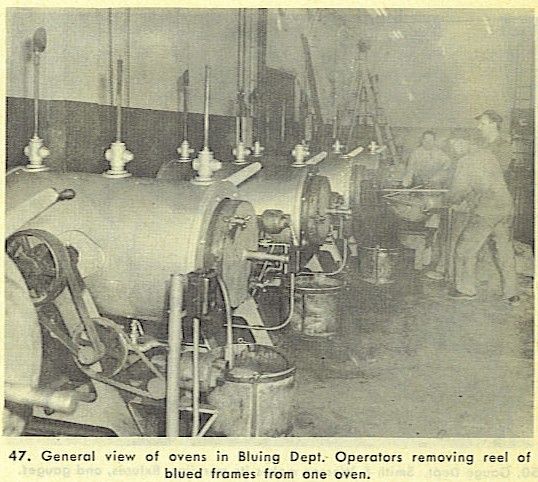

What do you think makes the difference between the two? The temperature? The length of time at a temperature? I know that if you place low grade steel into a type of crucible, fill it with wood charcoal and powdered bone, and then place an airtight top on, you can end up with bluish colors. I also know that Colt filled a type of cement basin three feet deep with high carbon content materials, heated in a furnace, took the barrel out, carded it, and repeated to get the desired black color. Maybe blue is the color first arrived at in the furnace bluing process? A sort of tempering? So it may be just the time at a temperature of the furnace?

Bob

What do you think makes the difference between the two? The temperature? The length of time at a temperature? I know that if you place low grade steel into a type of crucible, fill it with wood charcoal and powdered bone, and then place an airtight top on, you can end up with bluish colors. I also know that Colt filled a type of cement basin three feet deep with high carbon content materials, heated in a furnace, took the barrel out, carded it, and repeated to get the desired black color. Maybe blue is the color first arrived at in the furnace bluing process? A sort of tempering? So it may be just the time at a temperature of the furnace?

Bob

Last edited: