What uses have you found for a dial indicator in reloading? I have found I can use it to find bullet and neck runout while reloading.

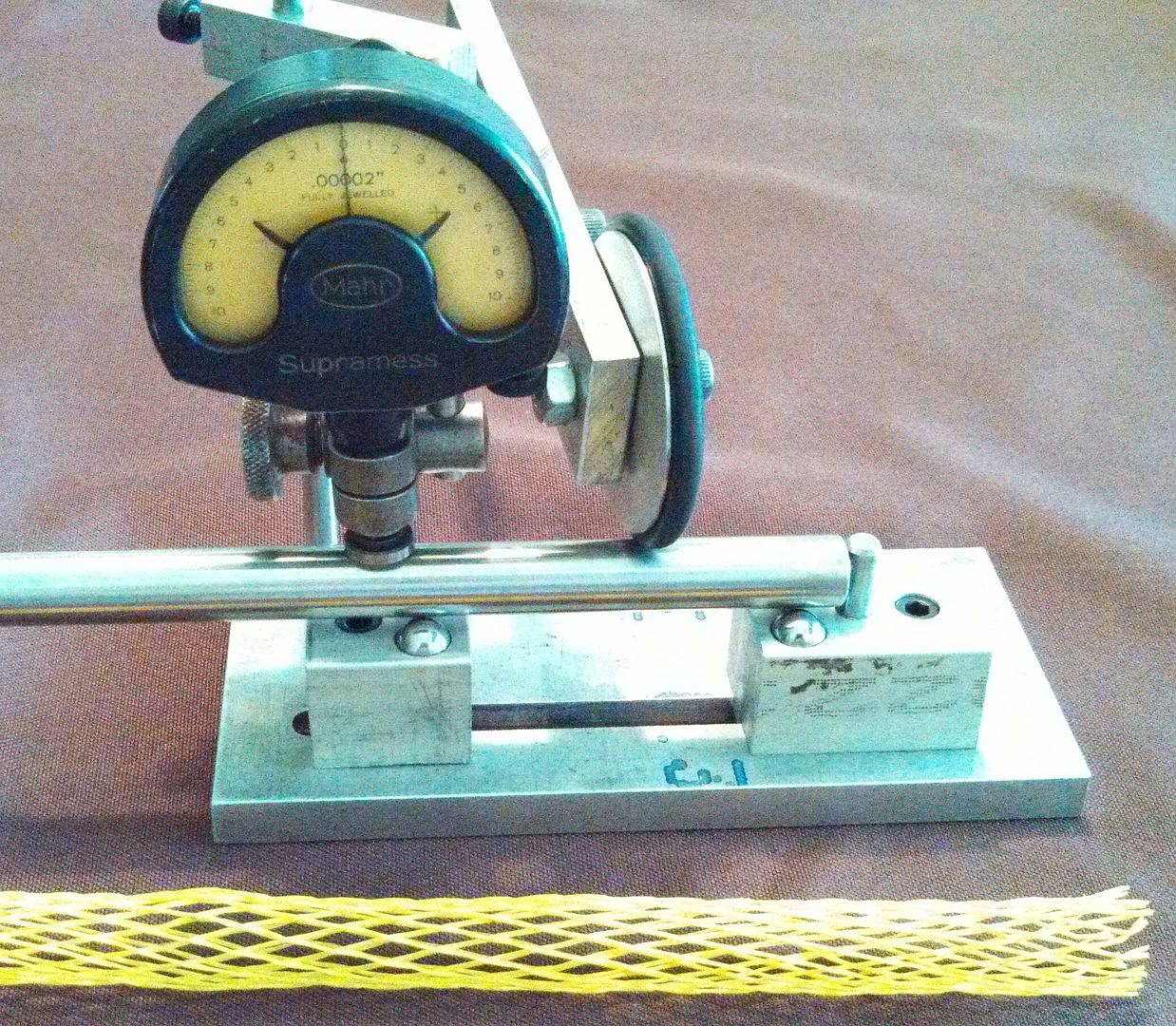

I also just found I can measure neck thickness using it in my K&M neck turning tool.

I’m looking for a setup to measure looseness in case gage (base to datum) and primer seating depth.

I also just found I can measure neck thickness using it in my K&M neck turning tool.

I’m looking for a setup to measure looseness in case gage (base to datum) and primer seating depth.