Been thinking about getting a .452 Lyman Hollow point mold and I have a question.

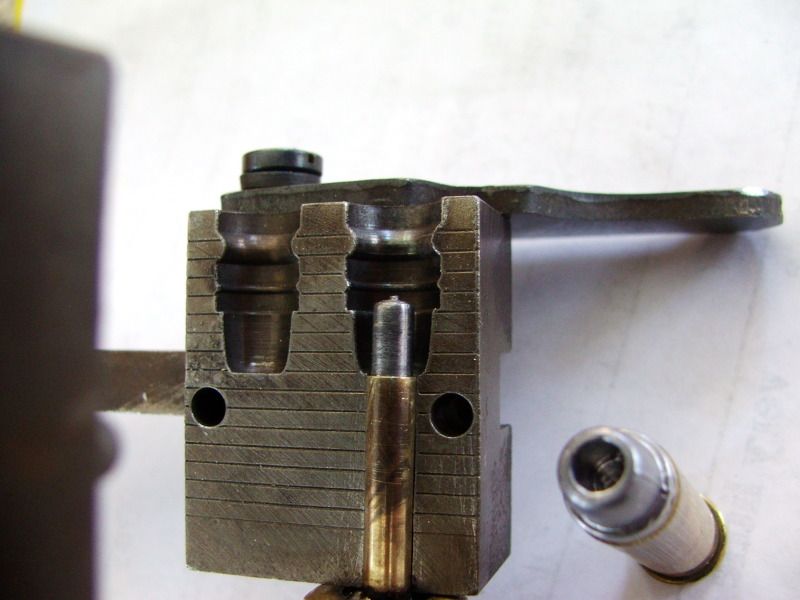

How or what makes the "hollow' point? The pictures on Midway and Lyman just shows a long cavity from bullet tip out the bottom of the mold. Obviously I have to put something in this cavity to form the hollow point, but what? Does it come with the mold or is it purchased separately?

Thanks

http://www.midwayusa.com/product/67...52-diameter-180-grain-devastator-hollow-point

How or what makes the "hollow' point? The pictures on Midway and Lyman just shows a long cavity from bullet tip out the bottom of the mold. Obviously I have to put something in this cavity to form the hollow point, but what? Does it come with the mold or is it purchased separately?

Thanks

http://www.midwayusa.com/product/67...52-diameter-180-grain-devastator-hollow-point