I cut some .45 over powder cards today using the wad cutter attachment that I ordered along with the Triple P loader.

I've been saving up wax board for this purpose.

The Triple P cutter worked great and with a minimum of effort, it was easily cutting perfect paper disks through up to 5 layers of wax board. Wax board containers come in a variety of thicknesses, so I chose to start with a medium thickness.

I'll probably order some Durofelt, but I wanted to see if it was really necessary. Plus the thicker felt wads may take away chamber space when loading conical bullets.

A single card was placed on top of the loaded powder in each chamber and rammed down.

Then after ramming the balls, I compressed another single card on top of the ball for good measure.

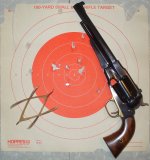

Here's another:

Next time I may load with 2 cards over the powder, but I wanted to try it out with just one first.

Next it will be off to the range to test them out.

Maybe a small amount of lube could be sandwiched in between 2 cards?

I've been saving up wax board for this purpose.

The Triple P cutter worked great and with a minimum of effort, it was easily cutting perfect paper disks through up to 5 layers of wax board. Wax board containers come in a variety of thicknesses, so I chose to start with a medium thickness.

I'll probably order some Durofelt, but I wanted to see if it was really necessary. Plus the thicker felt wads may take away chamber space when loading conical bullets.

A single card was placed on top of the loaded powder in each chamber and rammed down.

Then after ramming the balls, I compressed another single card on top of the ball for good measure.

Here's another:

Next time I may load with 2 cards over the powder, but I wanted to try it out with just one first.

Next it will be off to the range to test them out.

Maybe a small amount of lube could be sandwiched in between 2 cards?