I don't use the Lee collet dies, and so will not comment on them, other than I never found a need for anything like them.

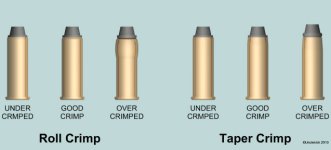

A couple points about taper vs roll crimp. With a taper crimp (and I assume a collet crimp, collet crimpers correct me if I'm wrong), you are squeezing more than just the case mouth. You are squeezing a portion of the case "neck" and the bullet, as well.

This has the potential to create problems when done wrong. (of course, what doesn't?

) The brass case, and the bullet are dissimilar metals, and while both will spring back a bit after being compressed, the amount will differ. Generally speaking the bullet will not "spring back" as much as the brass case, and when this situation is extreme, can actually loosen the fit of the bullet in the case (reduction of case neck tension) and that frequently is an unsatisfactory result.

With a roll crimp, the case mouth hits a "hard stop" on the crimp shoulder of the die, and since you are still pushing the case up into the die the case mouth gets bent into the bullet. BUT, only if it has someplace to go. A crimp groove and correct alignment of the case mouth in the groove are necessary.

(you can, usually get a light crimp on a soft lead bullet without a groove, but if the bullet is a harder material such as an alloy or jacketed, no groove is a problem)

IF there is no crimp groove (or the bullet is not seated correctly for the case to crimp into the groove), what will happen is that, as pressure is applied, the case will bulge somewhere below the case mouth. This can result in the case bulging away from the bullet, leaving little or no tension on the bullet, except at the actual crimp point. In bottlenecked cases, such as the .30-30, the bulge can be at the case shoulder, and can even bulge it so much it will not chamber. (yes, I've done both

)

Uncle Nick has some excellent illustrations showing this clearly. Hopefully, he will be along soon and share them again in this thread.

One of the commonly asked questions is "how much crimp do I need to use?" and that is very dependent on the load and the gun firing it. You will hear that you should only use enough crimp to keep the bullet from moving, and using more simply works the brass more than needed, leading to it failing sooner. This is true, however, the minimum needed varies with the specifics of your gun and load.

Some slow pistol powders need a firm crimp for reliable consistent ignition. Many do not. If the powder maker recommends it, do it.

You will hear the term "crimp jump" referring to revolvers, where the inertia of the bullet and the recoil of the revolver work to "pull" the bullet, so it appears to have moved forward, "jumping" the crimp.

This is absolutely a real thing, but again, its a variable thing, depending on many factors.

The usual check is firing 5 from a fully loaded cylinder, then checking the unfired round for bullet movement. Then doing it again with keeping the same round unfired. If there's no movement, you good to go.

HOWEVER, doing that in one gun does not mean its good for every gun.

Some years back I did a test, using uncrimped .38 Special rounds, (standard 158gr@850fps).

Fired through my S&W M28 6" they passed the jump test, the bullets did not move. Same (uncrimped) rounds fired through a J frame, the bullets DID "jump" (moved forward).

The difference here was the weight of the gun. The light gun recoiled more, and that "pulled harder", enough to overcome the case neck tension. The big Smith did not recoil as much, and the bullets stayed where they were seated, without any crimp.

In my test a light crimp provided the minimum needed for the light gun, and, of course, the heavy gun results didn't change at all.

A different load (heavier) would require more crimp to provide the minimum needed hold.

The standard factory crimp is done heavy enough so the ammo will work properly no matter what gun it is shot from.

IF you are looking for the minimum crimp needed, only testing with your stuff will show you that, and again, it will be gun/load specific.

Done right, more crimp than the minimum needed usually hurts nothing. Done wrong, results can be severely ...suboptimal.