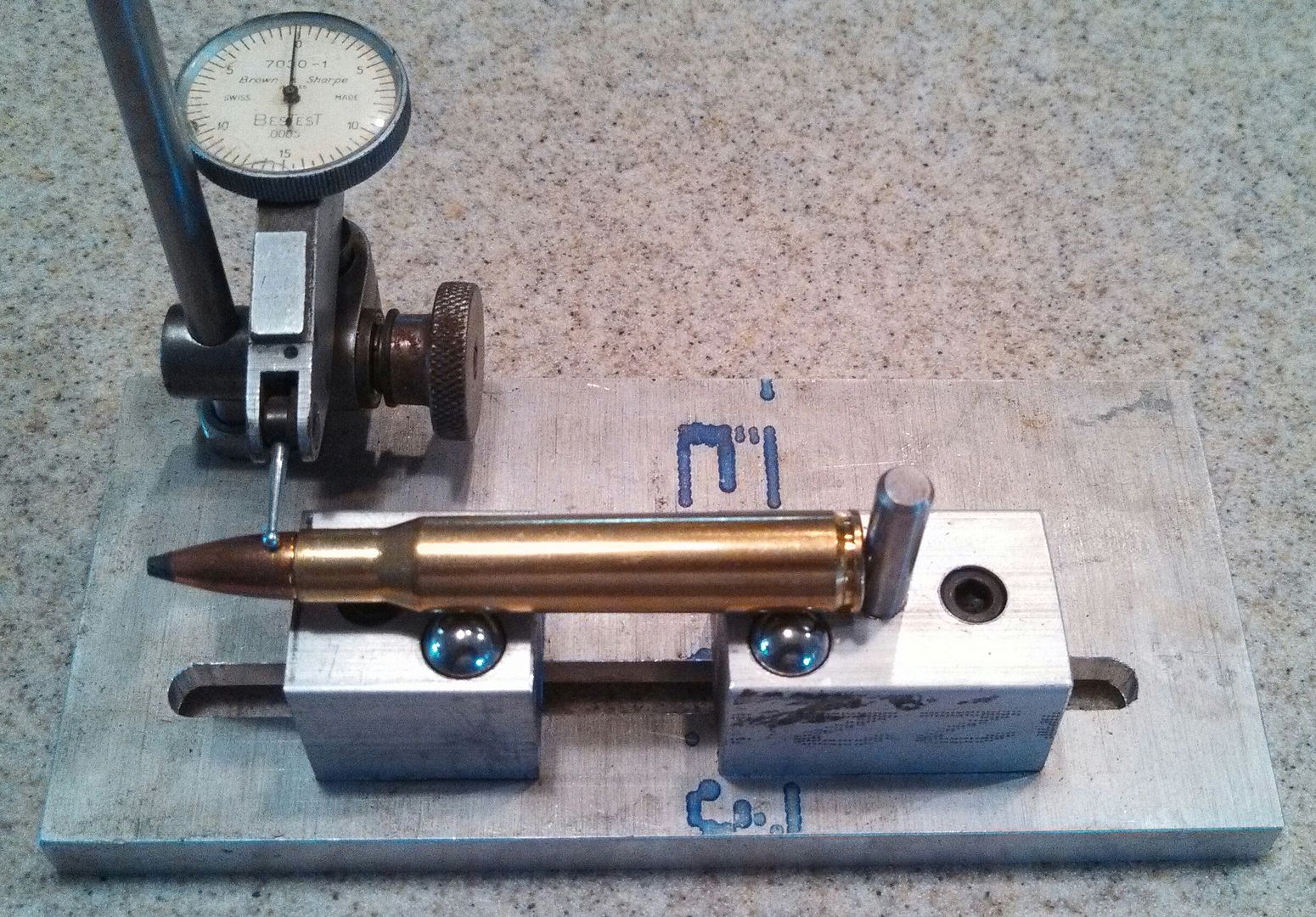

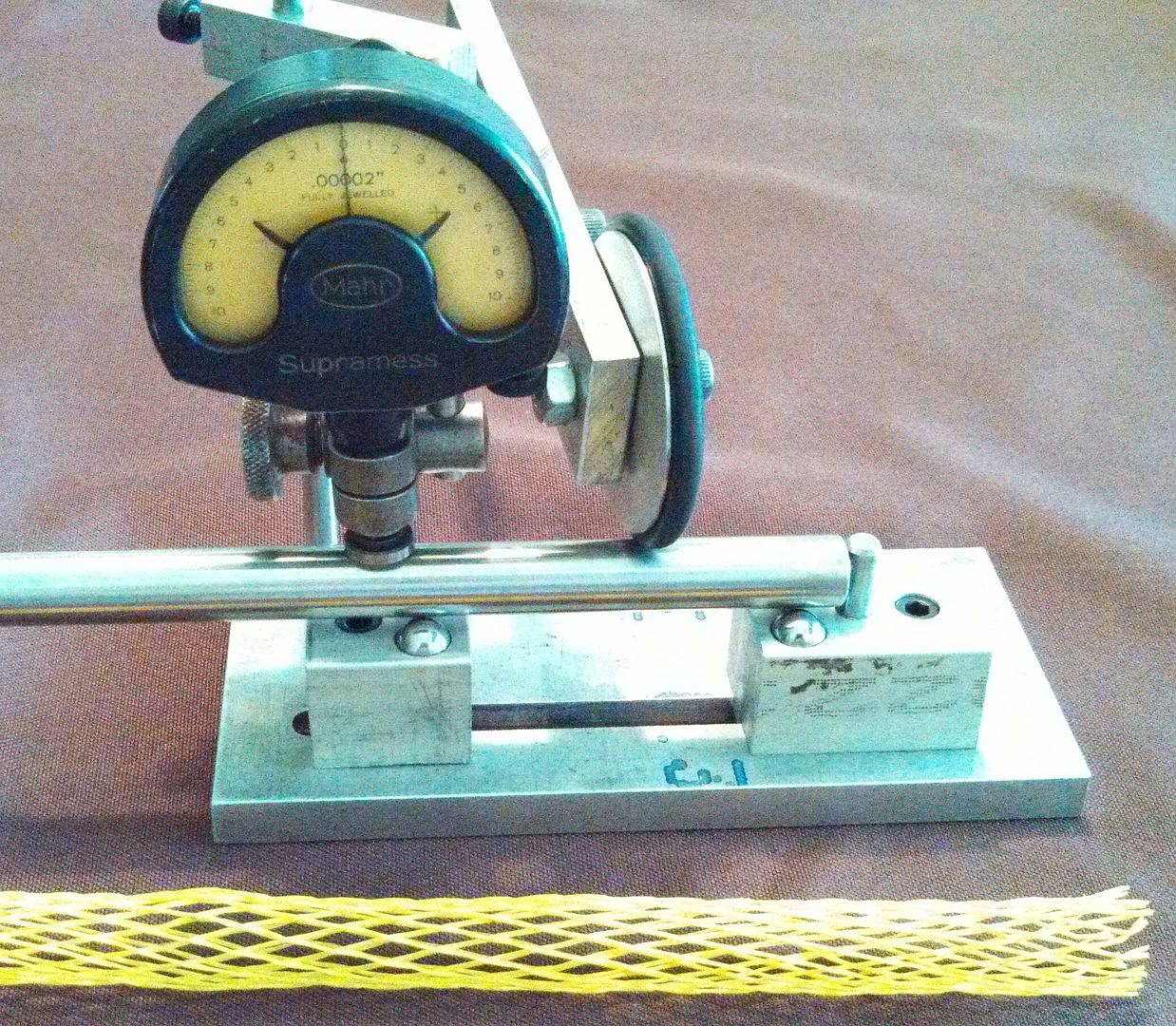

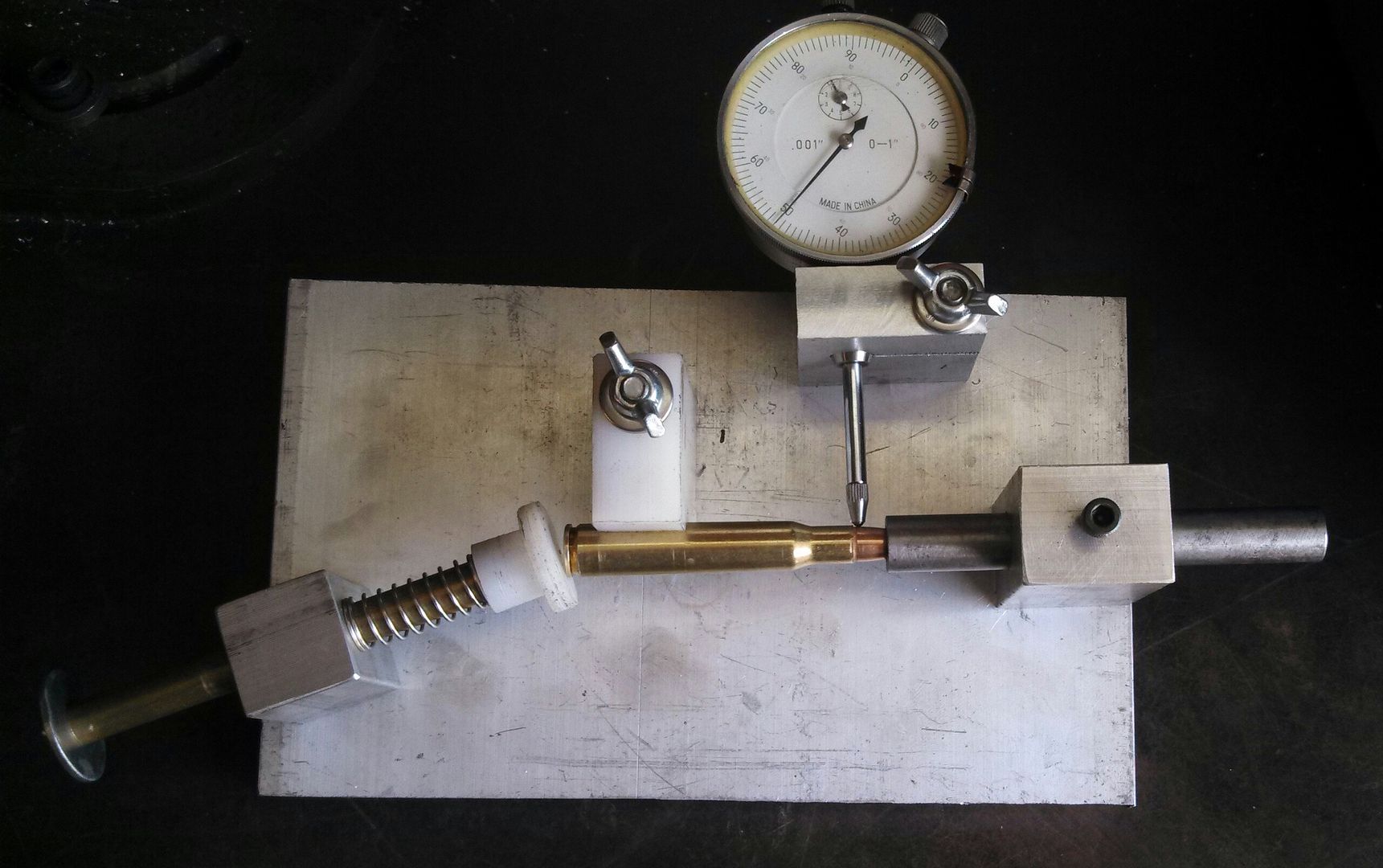

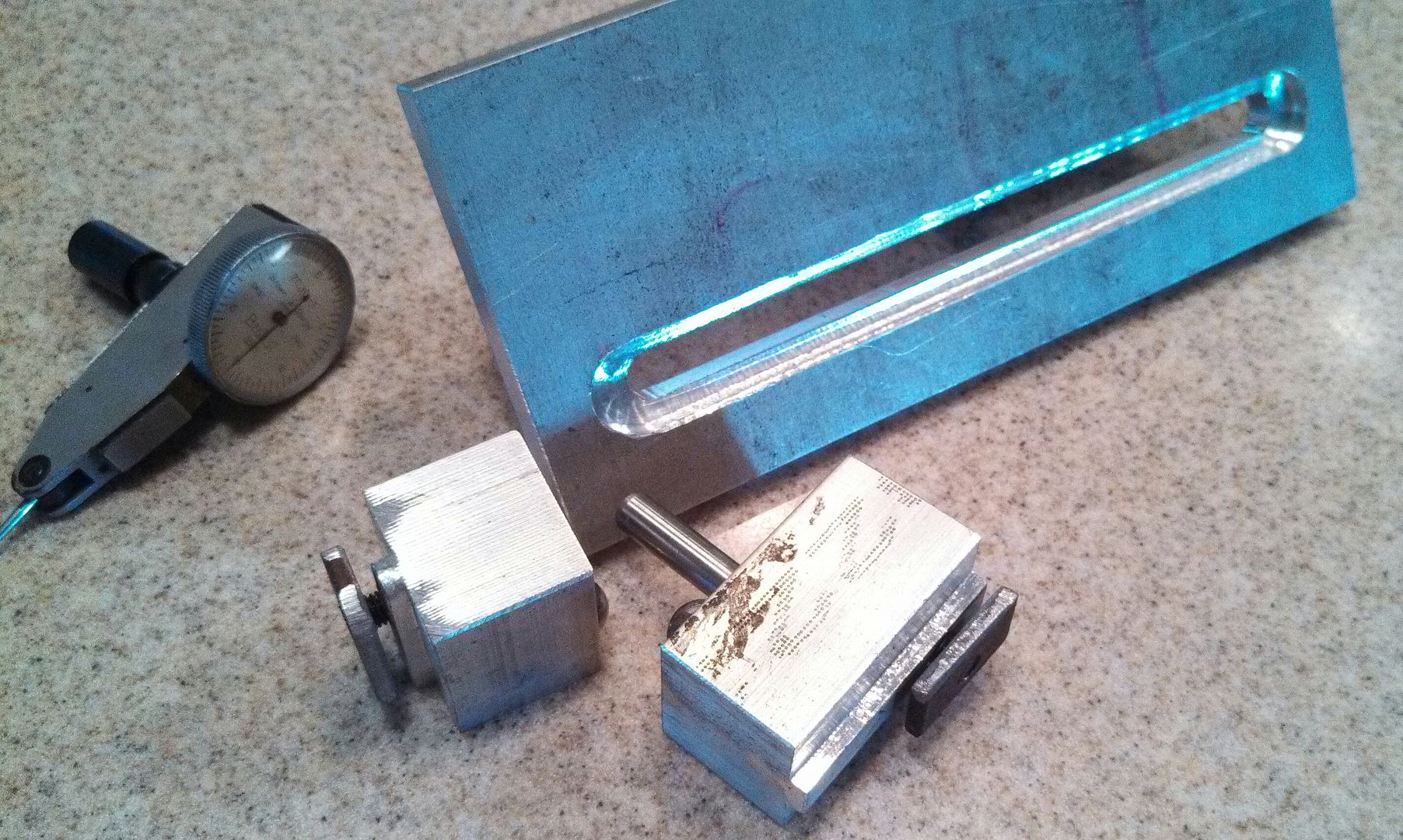

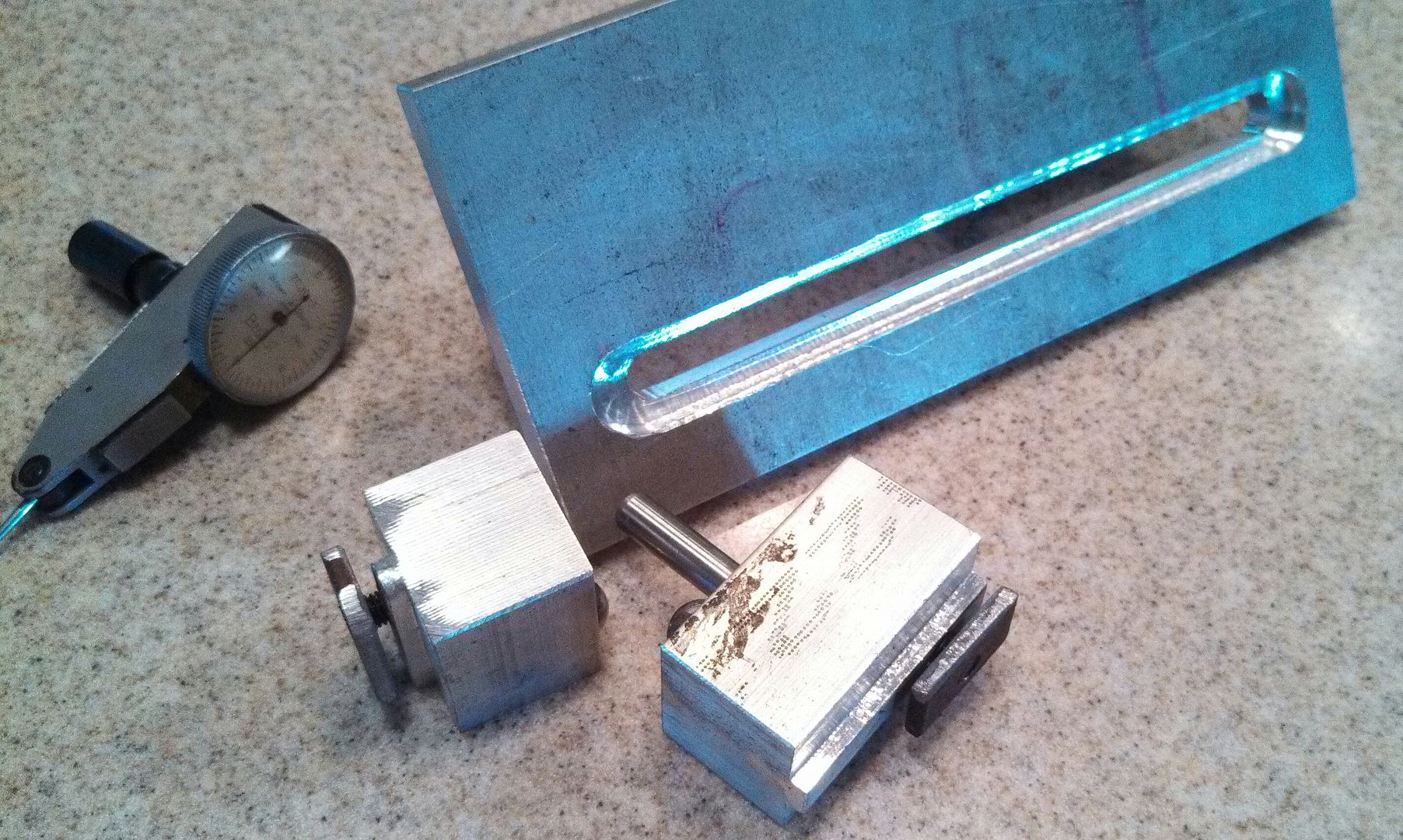

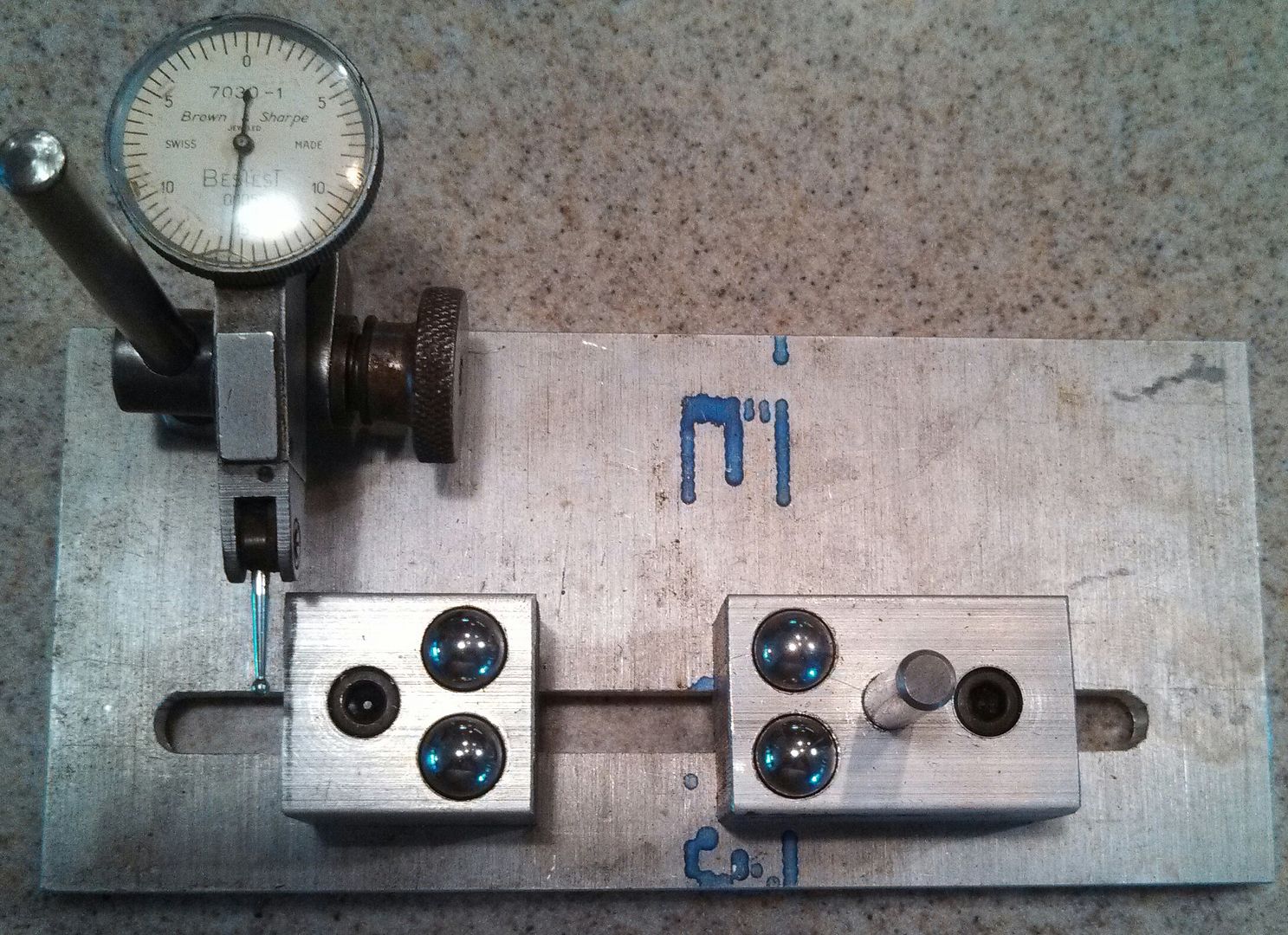

There have been a few times I have wished I had a simple little concentricity gauge dedicated to the reloading room for measuring runout in cases and to see how well bullets are being seated, so I built this one today.

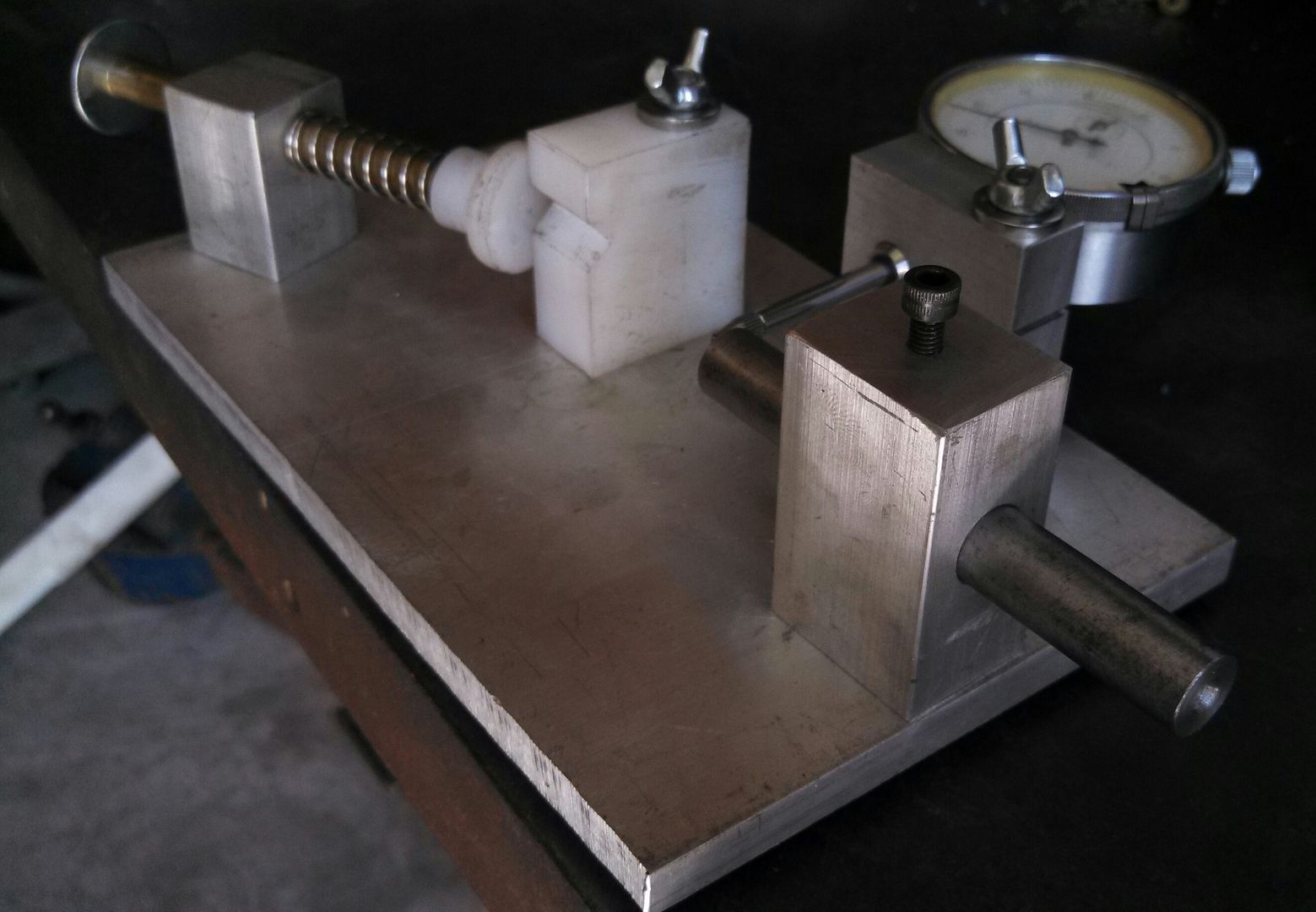

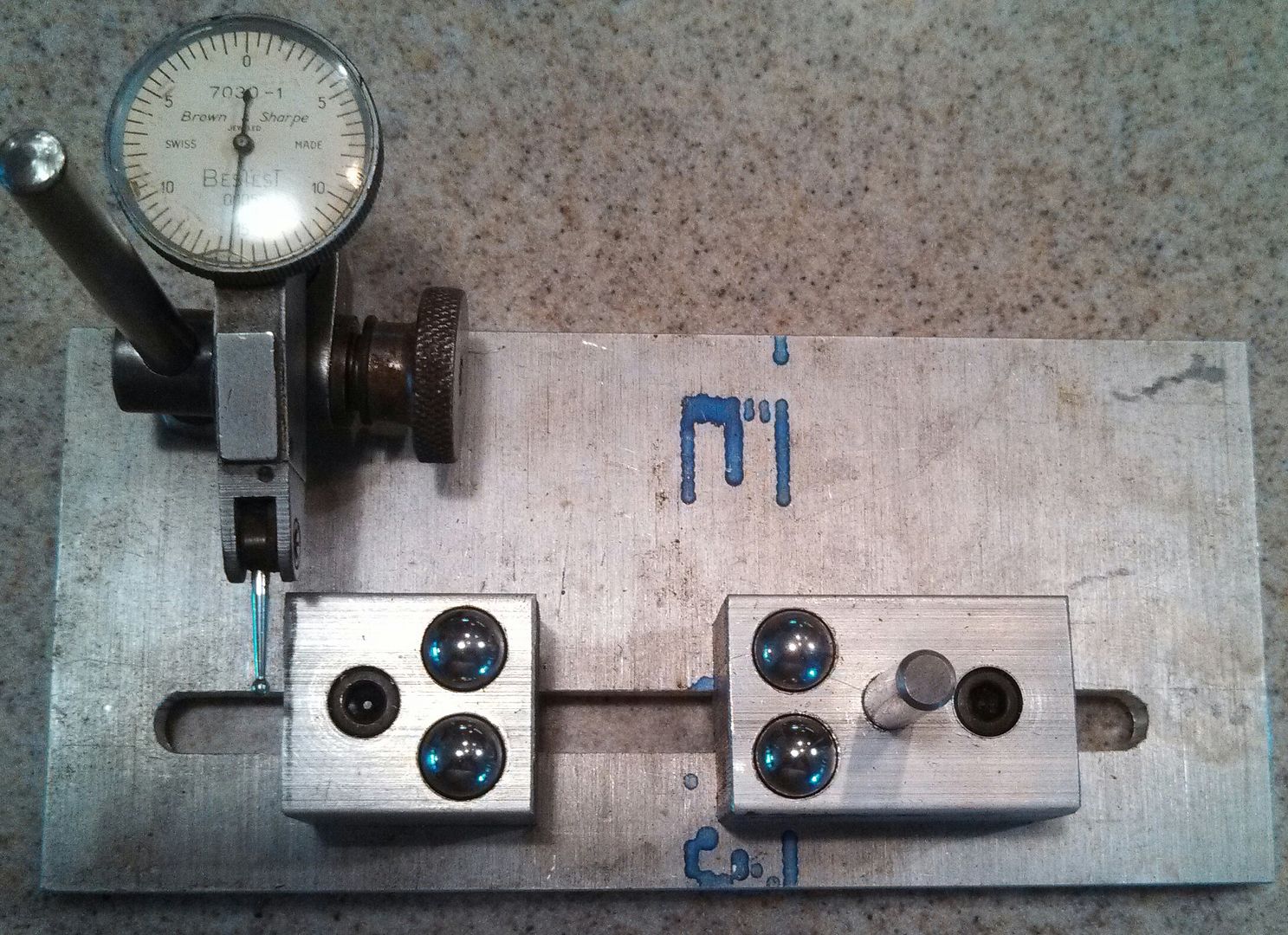

There is a slot machined into the base plate that the bearing holders ride in with an extra wide slot under that so the nut plate has clearance. This makes it so I just need one Allen wrench from the top to set it up.

The bearings are .375 and set into the aluminum carriers with Devon, I used a 1/4" stainless rod to mount one of my indicators to and a 1/4" dowel to locate the back of the case.

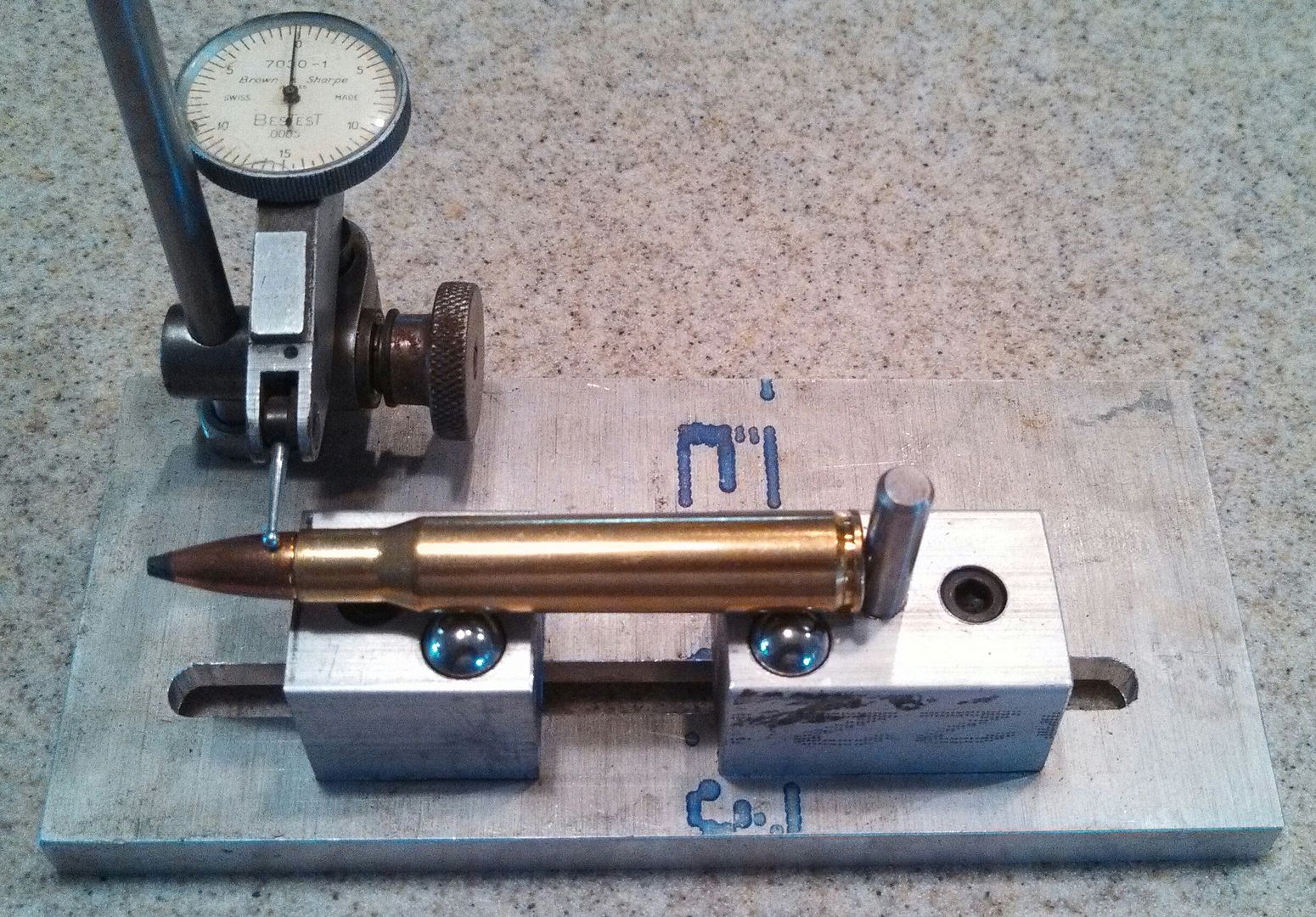

Tested it out on a precision ground dowel and it works but I think I am going to add a spring loaded wheel with and o-ring on the OD to act as a "tire" that holds the case down and back against the dowel and give my fingers something a little larger to turn.

There is a slot machined into the base plate that the bearing holders ride in with an extra wide slot under that so the nut plate has clearance. This makes it so I just need one Allen wrench from the top to set it up.

The bearings are .375 and set into the aluminum carriers with Devon, I used a 1/4" stainless rod to mount one of my indicators to and a 1/4" dowel to locate the back of the case.

Tested it out on a precision ground dowel and it works but I think I am going to add a spring loaded wheel with and o-ring on the OD to act as a "tire" that holds the case down and back against the dowel and give my fingers something a little larger to turn.