You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Comercial to Military Brass

- Thread starter bungiex88

- Start date

You are going to start using military brass instead of commercial brass. I have 308 W dies, I do not have a military set for 7.62 NATO. Many reloaders have trouble sizing machine gun fired brass, it is possible I have never had a case that was fired in a machine gun, If I did I did not notice it being more difficult to size.

F. Guffey

F. Guffey

I am not sure I understand your question. Are you saying you have received some Lake City military brass you want to reload?

If so, the only problem I see is to convert the crimped primer pocket so you can re-prime. This entails either using a cutter or a swage to remove the crimp in the primer pocket after de-priming the crimped primer.

I use a Dillon Super Swage 600 on my Lake City 5.56 brass. It also comes with the components for .308 and a couple of other calibers.

Otherwise, I think you will find the brass will then reload just as any commercial brass.

If so, the only problem I see is to convert the crimped primer pocket so you can re-prime. This entails either using a cutter or a swage to remove the crimp in the primer pocket after de-priming the crimped primer.

I use a Dillon Super Swage 600 on my Lake City 5.56 brass. It also comes with the components for .308 and a couple of other calibers.

Otherwise, I think you will find the brass will then reload just as any commercial brass.

4runnerman

New member

Im with Guffy here. Only difference is crimped primer and weight. A 308 die is a 308 die. Why Military brass?. Weights are all over the place- Accuracy will suffer unless you weigh all cases and pick out a certain weight.

Yup that's it.Remove the primer crimp(a one time thing), reduce your load by 10% and work up.

Marco Califo

New member

If you acquired U.S. (Lake City or LC YY) military once fired 7.62x51, then they were fired in a machine gun, with loose chambers and puffed out. All military 7.62 once fired is like that. First sizing tends to be very difficult to the extent you swear something is wrong. Go slow. Remove your expander ball from your die and only size the outside first. Good lube is critical. I use Lucas Bros. White Lithium grease, and it makes sizing these cases a lot easier. The primer crimp will need to be removed. I use a countersink drill bit and it just cuts away some of the offending brass. TRIM - your case lengths will be all over the place after sizing. Some will need possibly zero trim, while others will need 15+ thousands taken off. Personally, I prefer to buy this brass pre-processed to the full extent possible. It is worth it, unless you have the equipment and too much time on your hands. Weighing the cases, and separating into like groups is supposed to aid accuracy.

After you process the brass, all charges for 308 in 7.62 military brass should be reduced by about 2 grains, in addition to reducing 10% for your starting loads. This is

true for 7.62 which do have thicker brass. It is NOT true for 5.56/223 from LC which runs right on par with commercial 223.

After you process the brass, all charges for 308 in 7.62 military brass should be reduced by about 2 grains, in addition to reducing 10% for your starting loads. This is

true for 7.62 which do have thicker brass. It is NOT true for 5.56/223 from LC which runs right on par with commercial 223.

Last edited:

I use almost exclusively LC brass for my 308 . I agree with others that it has not been an issue for me to size and chamber in my rifles . I did have issues when I tried to use one shot case lube but stopped and went back to a wax based lube and never had an issue again . Can you feel a little more resistances at times ? Sure but with the proper lube they still size just fine .

If the OP is asking what to do if you have a load you've been shoot with commercial brass and now want to change to NATO brass . What I do is drop the charge 1.5gr and work back up . I in fact just did this with two different loads last week . I was able to load the new NATO brass to the old charge amounts with no pressure signs and same accuracy . AVG velocity was about the same as well . I should add that my loads are almost never at max charge so dropping 1.5gr usually puts me close to min loads or at least below the mid charge point .

oh and yes you will need to remove the primer crimp .

If the OP is asking what to do if you have a load you've been shoot with commercial brass and now want to change to NATO brass . What I do is drop the charge 1.5gr and work back up . I in fact just did this with two different loads last week . I was able to load the new NATO brass to the old charge amounts with no pressure signs and same accuracy . AVG velocity was about the same as well . I should add that my loads are almost never at max charge so dropping 1.5gr usually puts me close to min loads or at least below the mid charge point .

oh and yes you will need to remove the primer crimp .

Lake City brass is pretty good stuff. I have shot tens of thousands of rounds of LC in my various M1a's, bolt rifles. It is my recollection that my LC generally weighed between 175 and 177 grains per case. Commercial 308 brass varied more in weight than LC, I had Federal NM cases that were 155 grain. And I had some Federal NM cases that weighed 177 grains.

If what you have is machine gun brass, I would size the brass in a small based die. Just a good lube or you will stick the case in the die. I use RCBS water soluble or Imperial sizing wax. With surplus brass check to see if you have case head separation issues. Take a paper clip, bend it to a hook, and see if you can feel a inside ring. If you do, toss the brass.

I recommend you set up your dies with a case gage. You don't want to undersize or over size your brass.

If what you have is machine gun brass, I would size the brass in a small based die. Just a good lube or you will stick the case in the die. I use RCBS water soluble or Imperial sizing wax. With surplus brass check to see if you have case head separation issues. Take a paper clip, bend it to a hook, and see if you can feel a inside ring. If you do, toss the brass.

I recommend you set up your dies with a case gage. You don't want to undersize or over size your brass.

Slamfire nailed it. I got a great deal on 2.5K of LC 7.62 cases. All had been MG fired. I tumbled them clean, lubed with Imperial Sizing Wax and went to it. After the initial sizing through the SB die I did the primer pockets on the Dillon and trimmed to length. If you can get one for your trimmer the carbide cutter makes quick work of it.

Once processed though your good to go, just start low and work up.

Once processed though your good to go, just start low and work up.

LC nato machine gun brass can be bought once fired for cheap money, however be warned it's a b!tch to size, you have to anneal the necks or you will be beating the crap out of your press. Like others commented Imperial wax will be a big help. The nato brass is a few thousandths thicker than the civilian brass.

balderclev

New member

I've never understood this problem with 556/223 or 762/308 issues.

All my 223 rounds are resized lc 556 cases and my 308 rounds are 762 military brass. It is just much cheaper. I resize them, build a load, and shoot them. No problems ever. Of course, I have to remove the crimp the first time.

All my 223 rounds are resized lc 556 cases and my 308 rounds are 762 military brass. It is just much cheaper. I resize them, build a load, and shoot them. No problems ever. Of course, I have to remove the crimp the first time.

I've never understood this problem with 556/223 or 762/308 issues.

Just to be clear . The OP was not asking about the cases specifically per-say . He wanted to know if you have an existing load/cartridge that you've been loading using commercial brass . Can you just load that charge in LC or other NATO brass

And to clarify I had a load worked up in commercial brass but ended up running into good deal of Lake city for cheap.

My answer was drop down 1.5gr and work back up . I believe changing cases constitutes a rather large change in an already worked up load when it comes to center fire rifle cartridges . I personally don't work them back up from scratch when changing head stamps but rather just drop the charge down some and work back up comparing new to old .

I believe it's been shown that case weight has very little to do with case volume so IMHO when changing head stamp on an existing load . You should drop the charge weight a grain or two and work back up regardless of case weight .

Now when I do this I don't do the full work up . Meaning instead of 5 shots per load I'll load 3 Because I'm really looking for pressure signs then grouping . Then to confirm the new load is accurate . Instead of going back and loading 20 more of the new charge like I would in initial load development . I'll only load 5 or 10 to confirm the new load is in fact accurate before cranking them out 50 to 100 at a time .

YMMV

Last edited:

4runnerman

New member

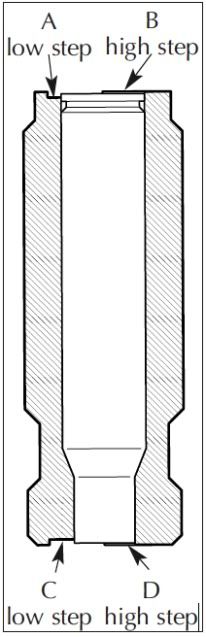

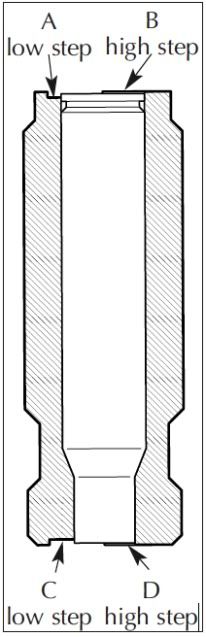

Metal- You lost me on that one.Case weight has little to do with case volume?.

My tests totally show it has a lot to do with internal volume. I have pictures in another post.

223 cases.

2- non military cases

2- military cases

All 4 cases loaded with 25.5 gn Varget. While the 2 non military cases show powder to just below the neck, the 2 military cases show powder 1/2 way up the neck ( compressed load it would be). Just saying

My tests totally show it has a lot to do with internal volume. I have pictures in another post.

223 cases.

2- non military cases

2- military cases

All 4 cases loaded with 25.5 gn Varget. While the 2 non military cases show powder to just below the neck, the 2 military cases show powder 1/2 way up the neck ( compressed load it would be). Just saying

I've read many an article that shows case weight had very little to do with volume but I guess there is more to that . That was when each of the cases were under 10gr from one another most were under 7gr difference . If the cases are 20+ grains different then they will have a volume difference . Unclenick brought up a good point when it comes to case volume . They all must be measured from fire formed cases from the same chamber. All must be trimmed to the same length as well . I'm on my phone now . When I get home I'll link the article with test results

Last edited:

Here you go http://www.6mmbr.com/223rem.html, check out the weight to case volume test about 1/3 of the way down the page . The PMP that weighs 104.5gr @ 29.9gr of volume and the Federal weighs 96.3gr @ 30.2gr of volume . That's over 8gr in weight with only a .3gr difference in volume . That will not be noticed when loading .