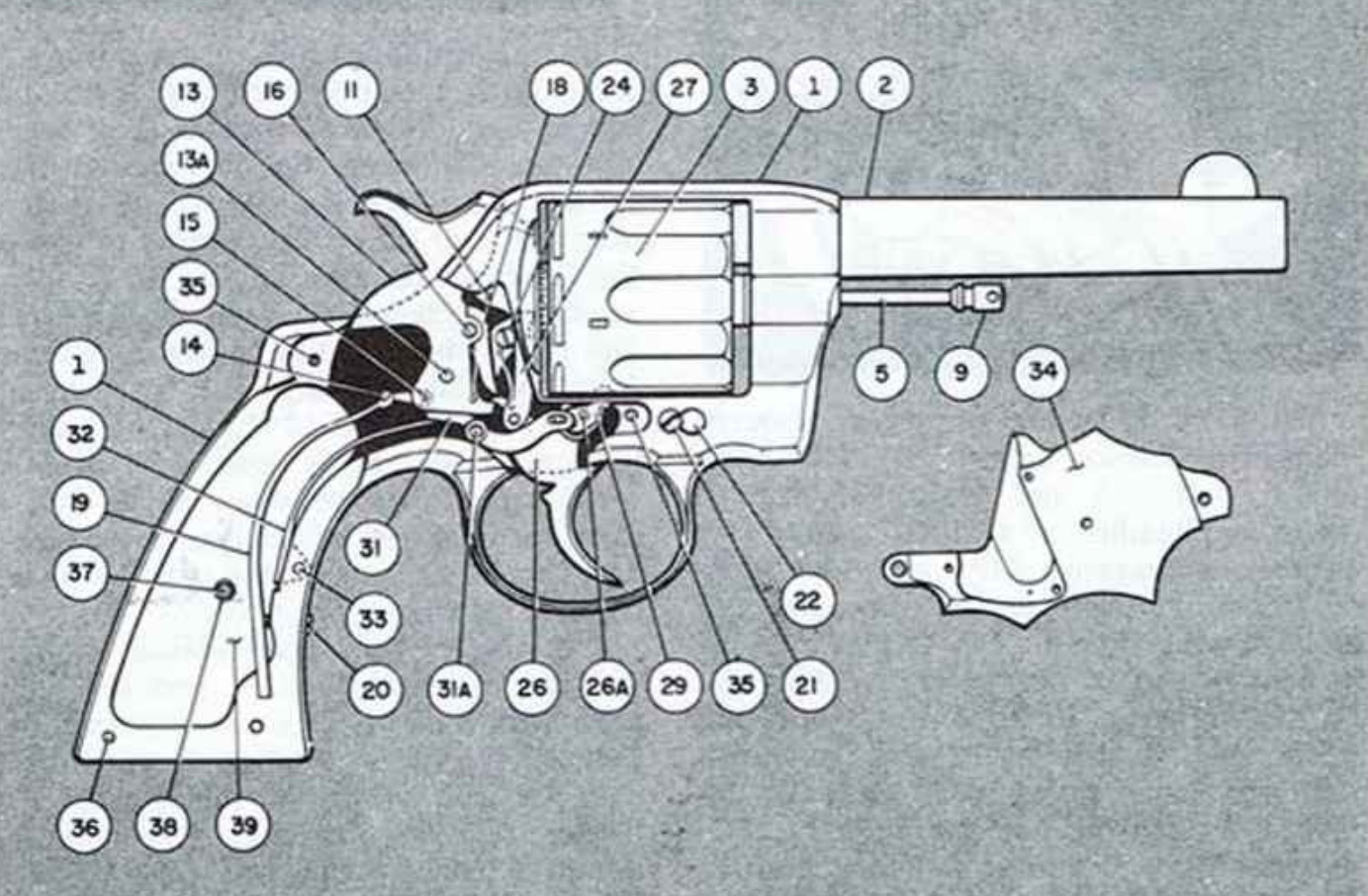

Colt 1894 .38 New Army & Navy

I have a Colt 1894 .38 Army & Navy and it will not cycle the trigger can be pulled but the hammer only move abot a 1/8 of a inch. The cylinder will not cycle to the next chamber either. Can I fix this or should. I take it to a gunsmith?

Thanks

I have a Colt 1894 .38 Army & Navy and it will not cycle the trigger can be pulled but the hammer only move abot a 1/8 of a inch. The cylinder will not cycle to the next chamber either. Can I fix this or should. I take it to a gunsmith?

Thanks

Last edited: