IllinoisCoyoteHunter

New member

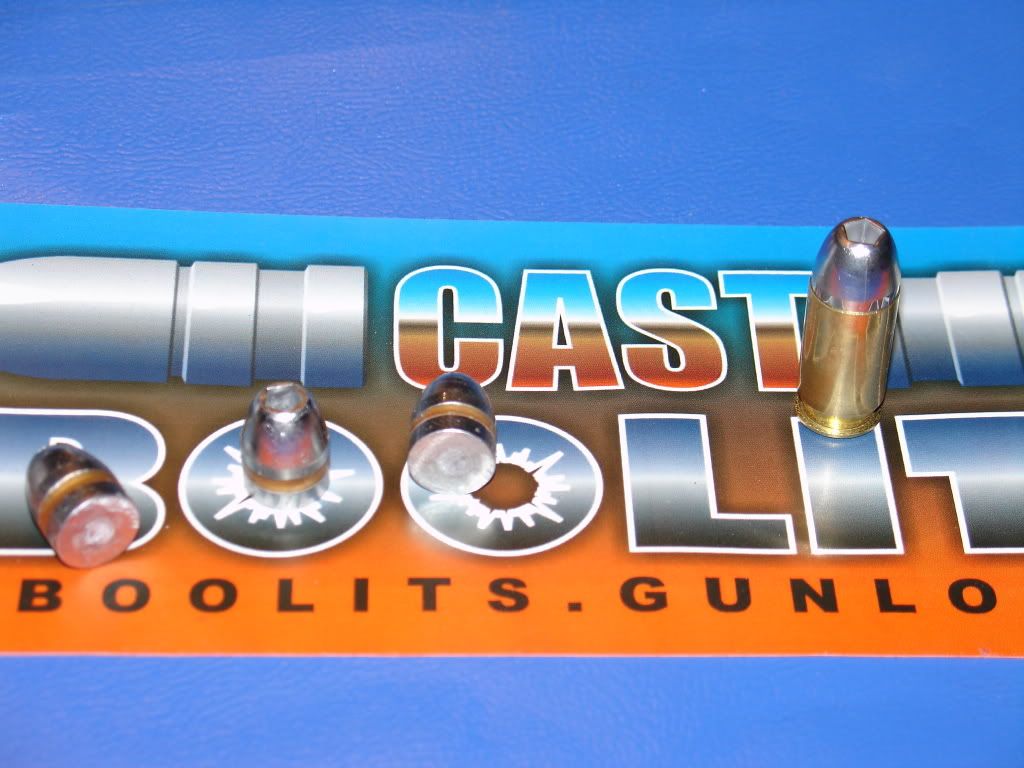

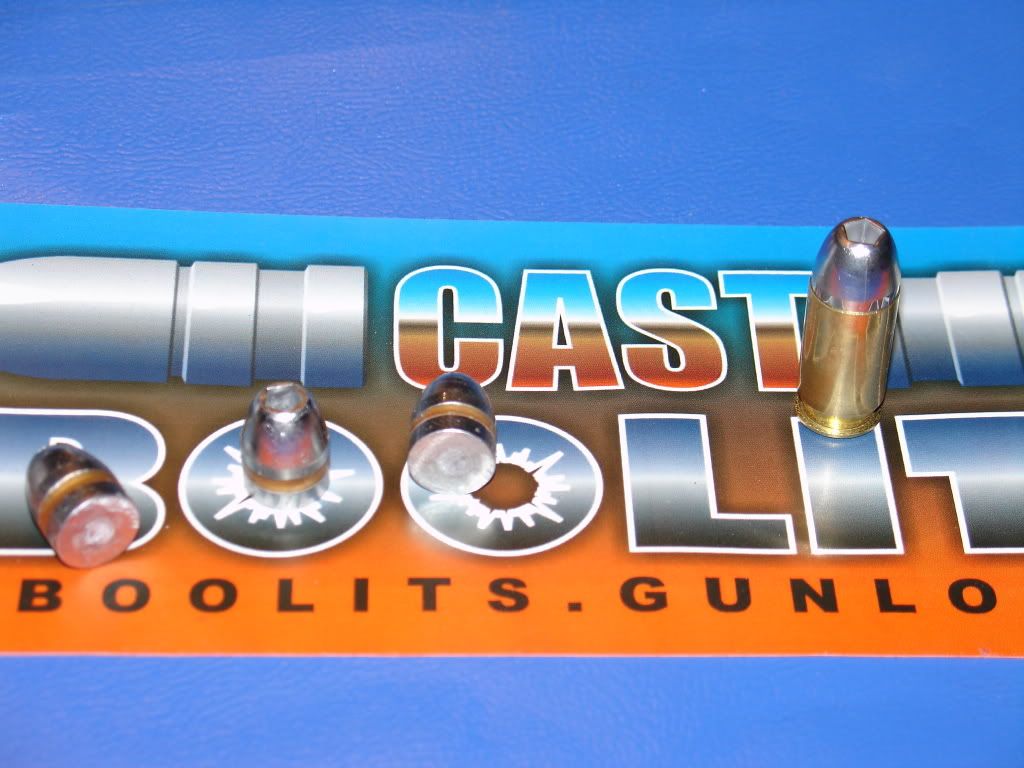

For all those who have never seen one of these this a two-cavity brass mold with cramer-style hollow point pins...sometimes referred to as cramer molds. This style of HP casting has many advantages. The main advantage is that the pins stay hot because they stay in the mold and use the heat from the mold to stay hot. Casting with these molds is fast and easy. To do so, pour alloy as usual and break sprue. After breaking the sprue, turn the mold upside down, open the cavity, and slide the pins out (towards the opposite mold block half). The bullets fall off the pins. Carefully close the mold and start over. Great design!

This mold happens to be a .453 HP mold with round HP pins and Pentagonal HP pins. Plus, either set of HP pins can be turned around and flat nose bullet can be cast. 3 different styles of bullets in one mold. The bullets in the pic are sized to .452" and lubed with WhiteLabel BAC lube. Expansion test to come in the future...

This mold happens to be a .453 HP mold with round HP pins and Pentagonal HP pins. Plus, either set of HP pins can be turned around and flat nose bullet can be cast. 3 different styles of bullets in one mold. The bullets in the pic are sized to .452" and lubed with WhiteLabel BAC lube. Expansion test to come in the future...