You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

case prep center ?

- Thread starter rebs

- Start date

Oh man I need one bad . I just finished prepping 800 LC-16 cases . It took hours to do so . It was the most I've ever tried to do in one lump some . I could not do it and had to split it in to two 400ct lots . Cleaning , sizing and removing primer crimp were not to bad . How ever trimming and deburring took for ever . I not only had to split the lot in two . It then took each lot a couple days to finish 1/2hr or so at a time .

I've been looking at different prep centers or trimmers and they always seemed to cost to much . After prepping those 800 cases . I'm ready to spend any amount to save the time .

For me I've been looking at the

Lyman Case Prep Xpress Case Prep Center

http://www.midwayusa.com/product/211733/lyman-case-prep-xpress-case-prep-center-115-volt

Or the Frankford arsenal one

http://www.midwayusa.com/product/628405/frankford-arsenal-platinum-series-case-prep-and-trim-center

I'm leaning towards the Frankford because it trims as well .

I've been looking at different prep centers or trimmers and they always seemed to cost to much . After prepping those 800 cases . I'm ready to spend any amount to save the time .

For me I've been looking at the

Lyman Case Prep Xpress Case Prep Center

http://www.midwayusa.com/product/211733/lyman-case-prep-xpress-case-prep-center-115-volt

Or the Frankford arsenal one

http://www.midwayusa.com/product/628405/frankford-arsenal-platinum-series-case-prep-and-trim-center

I'm leaning towards the Frankford because it trims as well .

Last edited:

Personally I have small output of ammunition. Although I do understand the lack of productivity when producing 500 or more rounds efficiently in a reasonable length of time.

Perhaps a dedicated case prep area set up separated but near the press area.

If cleaning the cases is required then of course that would be first. In some cases a sorting system for incoming cases.

Of course the press or presses should be efficient.

To be able to quickly change over would save a lot of time.

Keep this one going for all of us.

Perhaps a dedicated case prep area set up separated but near the press area.

If cleaning the cases is required then of course that would be first. In some cases a sorting system for incoming cases.

Of course the press or presses should be efficient.

To be able to quickly change over would save a lot of time.

Keep this one going for all of us.

Fotheringill

New member

There are a lot of steps to take in reloading. It can be absolutely mind numbing to do it in lots of 500, or for me, 100. To help preserve my sanity, I never do any step, except tumbling, in a lot of more than 50. It may be extra time going to another room or place on my bench for the next step, but it is a minimal waste of time. Try smaller lots because I would bet that part of the travail is the repetition of something 500 times that is getting you down instead of breaking things up a bit.

For example, if you use an electronic dispenser such as a Charge Master or Lyman Gen 5 or 6, let your mind take you back to sitting there waiting for the last .1 grain to hit that pan 500 times.

For example, if you use an electronic dispenser such as a Charge Master or Lyman Gen 5 or 6, let your mind take you back to sitting there waiting for the last .1 grain to hit that pan 500 times.

I use a Lee deluxe quick trim, so my case prep occurs on my press. It's messy as brass trimmings find their way everywhere, but I don't shoot super high volume .223 and it forces me to conduct press maintenance (which I should do willingly anyway). I have processed about 1500 this year though, which is more than usual. It's not too bad. I'll break it down into 200-400 round lots and take my time doing it. I cleaned, sorted, lubed, and sized 450 pieces over the past 2 or 3 weeks. This past weekend I trimmed, cleaned the primer pocket (and cut a few crimps off), and primed 200 of them. I trimmed another 100 last night, and will prime them tonight. I just work at my own pace and it's really not so bad.

I honestly hate lubing, sorting, and inspecting worse than anything, but at least I can sit on the couch and watch TV while I do that.

I honestly hate lubing, sorting, and inspecting worse than anything, but at least I can sit on the couch and watch TV while I do that.

shootniron

New member

I have the RCBS...it does pretty well, but there might be others that are better.

I have and use the RCBS version simply because it was given to me as a gift. Overall it works fine but before it I just did what needed done manually. Since I like removing carbon and crud from primer pockets it works great for that. Also great for chamfering and deburring case mouths. I would guess it is a matter of looking at features and what each does case by case and deciding what you want and what your budget is.

Ron

Ron

berettaprofessor

New member

Franklin Arsenal; love it. Get the accessory decrimp/pocket tools as well. Worth it.

turtlehead

New member

I've had the Lyman for two days.

It comes with all the tools and I happen to have another near full set from my Lyman hand tool.

It seems great. Very solid. Very quiet. I'm happy. Was on sale for $90.

Someone also sells a trimmer mod for it.

It comes with all the tools and I happen to have another near full set from my Lyman hand tool.

It seems great. Very solid. Very quiet. I'm happy. Was on sale for $90.

Someone also sells a trimmer mod for it.

JeepHammer

Moderator

Before you jump into an 'All In One' unit,

There might be some considerations you want to discuss...

The first one off the top of my head is no guides for cutting processes.

That means 'Angle Of Finger' accuracy on cutting functions like primer crimp removal & primer pocket reaming.

If you can bend the case back into shape, getting the shoulder/Datum Line back where it belongs (a lot can't),

Then consider a trimmer that does all three cuts, Length, Inside Taper, Outside Champfer at the same time instead of three different functions.

(Saves a crap load of time & finger stress)

Girard (? spelling) and the 'Trim It II' are both powered trimmers that index off the Datum Line on the case shoulder & both will do three cuts at once.

Flat face cutters, even powered units, leave you deburring/tapering/champfering in separate processes.

Not a big deal with 10 or 20 cases,

Do a couple thousand and you will see the benifit in doing all three cuts at once!

There might be some considerations you want to discuss...

The first one off the top of my head is no guides for cutting processes.

That means 'Angle Of Finger' accuracy on cutting functions like primer crimp removal & primer pocket reaming.

If you can bend the case back into shape, getting the shoulder/Datum Line back where it belongs (a lot can't),

Then consider a trimmer that does all three cuts, Length, Inside Taper, Outside Champfer at the same time instead of three different functions.

(Saves a crap load of time & finger stress)

Girard (? spelling) and the 'Trim It II' are both powered trimmers that index off the Datum Line on the case shoulder & both will do three cuts at once.

Flat face cutters, even powered units, leave you deburring/tapering/champfering in separate processes.

Not a big deal with 10 or 20 cases,

Do a couple thousand and you will see the benifit in doing all three cuts at once!

turtlehead

New member

Giraud Tri-Way trimmer. Worth it's weight in gold.

Under $100.

Under $100.

The first one off the top of my head is no guides for cutting processes.

Very good point to keep in mind . Right now I'm using the Lyman universal case trimmer with drill attachment . It has pilots that slide inside the neck when cutting . How ever I found when trimming some cases . There is so much material cut off that the pilots get stuck and I can't withdraw the cutting arm . So I started using it with out the pilots and have not had an issue .

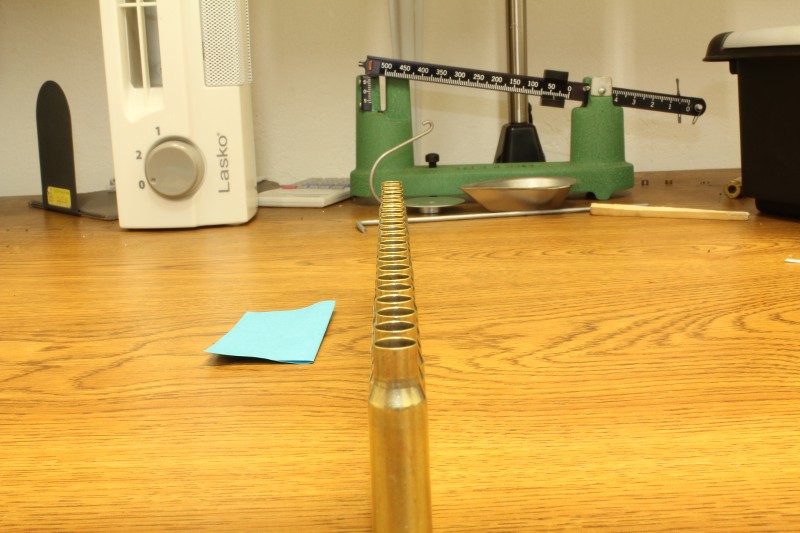

It cuts the mouth very square to the case body . Here's a pic of the cases stood on there mouths showing they do not lean one way or the other .

To give you an idea how that method of standing them up works .You line 10+ cases up using a straight edge so they are perfectly inline with one another at the base . If they are square to the surface they are setting on the tops should line up straight down the line . Here is a pic of some cases that were fired from a firearm with an out of square bolt face . This resulted in the case heads being canted after firing . Notice how the case mouths don't line up down the line

As apposed to these that are nice and straight

So yes making sure things are square is important and is measurable .

Last edited:

Here is my prep center. I bolted the Frankford Arsenal to the board along with the RCBS Trim Pro. The gladware container was cut down and fitted as a catch can for shavings/carbon.

I only use the FA to trim .223 since I prep them by the thousands, I use the RCBS for my low volumne/high accuracy loads for the .243, 30-06, 30-30, .44mag, 357mag.

But I do use the debur/chamfer feature of the FA for all of the cases I trim.

The way I was doing this chore before the FA was labor intensive and still makes my hands cramp thinking about it!

I only use the FA to trim .223 since I prep them by the thousands, I use the RCBS for my low volumne/high accuracy loads for the .243, 30-06, 30-30, .44mag, 357mag.

But I do use the debur/chamfer feature of the FA for all of the cases I trim.

The way I was doing this chore before the FA was labor intensive and still makes my hands cramp thinking about it!

Doublehelix3216

New member

I've got the Lyman Case Prep Xpress that I use for primer pocket work, and a Giraud Tri-Way Trimmer mounted on a customer motor drive for case trimming.

Both are amazing!

Both are amazing!

disseminator

New member

I've got and recommend the Lyman. It works great and being top mounted, it collects all the brass trimmings and keeps your work area neat.

For Swaging Mil brass, get the Dillon Super Swage. It will make short work of brass prep. And finally, I use the WFT for 223 and it does such a job I don't bother reaming or chamfering anymore.

I prep mine in lots of 1000 give or take. Much nicer than doing 100 at a time. I have about 3500 ready to load right now and I won't need to prep them again for quite some time which is nice.

For Swaging Mil brass, get the Dillon Super Swage. It will make short work of brass prep. And finally, I use the WFT for 223 and it does such a job I don't bother reaming or chamfering anymore.

I prep mine in lots of 1000 give or take. Much nicer than doing 100 at a time. I have about 3500 ready to load right now and I won't need to prep them again for quite some time which is nice.