Fretless,

I think you may be confusing headspace with head dimensions. Headspace is a confusing term, so I'll explain it here for anyone else reading, even if that's not the issue with your description.

First, it is important to understand that headspace is actually a chamber dimension and not a cartridge case dimension. The term comes from rimfire cartridges, for which the rimed portion of the case is also the head (the pressure barrier). Headspace in a rimfire chamber is literally the amount of front-to-back space the chamber has for the head to fit into. It's the distance from the breechface (the bolt face in a rifle) to the bottom of the recess cut for the rim of the cartridge to fit into.

The importance controlling the chamber headspace when you make a gun is threefold. It determines how far the firing pin can drive the loose fitting cartridge forward before it meets enough resistance for the pin to ignite the priming mix. It determines how much the case will have to expand while containing pressure, a situation for which over expansion risks breeching the brass and leaking hot, high pressure gases than can damage the gun and shooter. The looseness of the fit can affect accuracy the weapon.

Over time, as centerfire cartridges were developed, headspace ceased to mean room for the case head in the chamber, but rather came to mean the distance from the breech face to whatever surface stops the cartridge from moving further forward. For rimfire cartridges and rimmed centerfire cartridges, this is still the rim. For an auto pistol cartridge its the distance from the breech to the shoulder in the chamber that the case mouth stops against. For a belted magnum cartridge it's the distance from the breech face to the step in the chamber that the belt of the case stops against. And for a bottleneck cartridge case, like a .223/5.56 NATO, it's the distance from the breech face to the shoulder of the chamber profile.

In that last instance, the bottleneck rifle case, the shoulders is a conical surface, so the question arises as to where on the shoulder's slope you want to measure the headspace from? It used to be taken from the breech face to the point where the shoulder meets the side of the case body (body/shoulder intersect, actually). You will find Hatcher and other older writers using this number. The problem with it is that since chambers have to be slightly wider than cartridge cases for cartridges to slip into the chamber freely, the case doesn't actually stop against that corner. Rather it centers in the cone of the shoulder and is stopped by part of the chamber shoulder is further forward. So, something had to be changed.

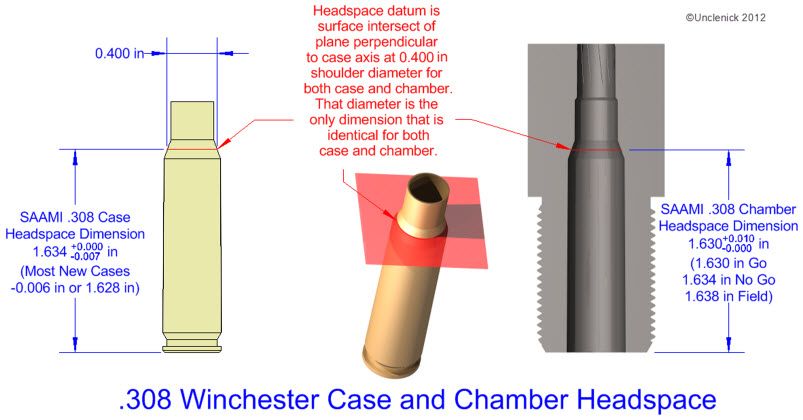

The solution was to declare a particular diameter of every cartridge design's shoulder to be the diameter used measure both the chamber and cartridge cases from to determine fit. So, it is the distance from the breech face of the closed bolt to that particular diameter on the chamber shoulder that is called the headspace of your rifle. The measuring diameter is called the shoulder datum. Datum is is just a word that means a defined measuring reference. If you look at chamber and cartridge drawings, because both have tolerances in opposite directions, the only dimension that is the same for both is that shoulder datum.

A habit that has developed is to refer to measuring from the outside of the case head to the shoulder datum on the case as Case Headspace. It's actually the headspace-filling space on the case, and how much smaller it is than the chamber headspace determines how loose the fit is.

Below is an illustration of the .308 Winchester's chamber and case headspace and where the shoulder datum is located, as determined by a plane perpendicular to the axis of both chamber and cartridge that passes through the shoulder at the SAAMI specified datum diameter for the .308.

For your .223, the shoulder datum diameter is 0.330", but the principle is the same. You'll notice case headspace maximum is often larger than chamber headspace minimum. This is because the chamber is fatter than the case and a closing bolt can easily compress a case enough to expand it to fill the chamber. However, that practice is not best for accuracy or feeding. It is merely acceptable as a limit.

As to your problem of narrowing a case head, the case head is much thicker brass than the rest of the case all the way to the 0.125" deck height of the case holder. You should not need to size it any further down than that. If you do, it suggests the brass is either defective or has been expanded to a degree that indicates it was subjected to unsafe pressure. In that instance the case should be tossed.