Mr. Guffey is giving both excellent advice and a good example of gas bypass.

If you look online for some of the super high speed slow motion video of bullets firing, you see the puff of bypass gas that precedes the bullet to the muzzle. Dr. Lloyd Brownell describes how it is affected by seating depth and how it, in turn, affects peak pressure. Look at pages 45-51,

here.

The main thing is that pressure expands the brass at the neck away from the bullet faster than it can move the bullet mass significantly forward. Therefore, gas starts leaking out at the case mouth and goes around the bullet until the bullet covers the free-travel distance (aka, bullet jump to the lands) so its widest diameter can begin creating a seal. That's the gas you see preceding the bullet in the slow motion videos.

Pressure peels the neck brass from the bullet starting at the bullet base and moving forward. At the moment the lifting of the brass reaches the case mouth, gas starts to escape, creating a pressure drop that stops the neck being expanded much further. The result, which you can find on any rifle case, is the mouth of the case hasn't expanded quite as much as the rest of the neck below it. Often, if the chamber neck isn't too loose, you find a new bullet will not fall into it until you expand it slightly.

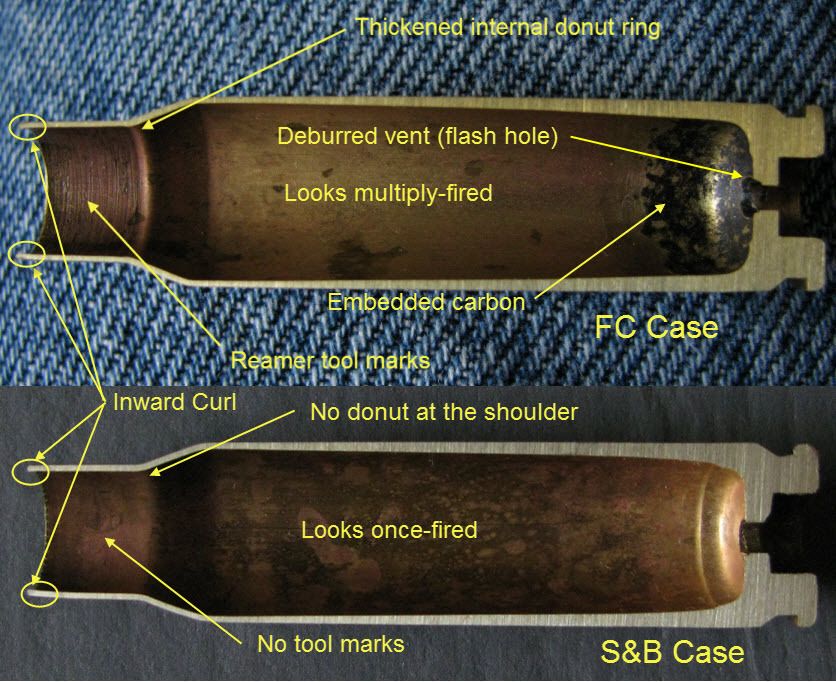

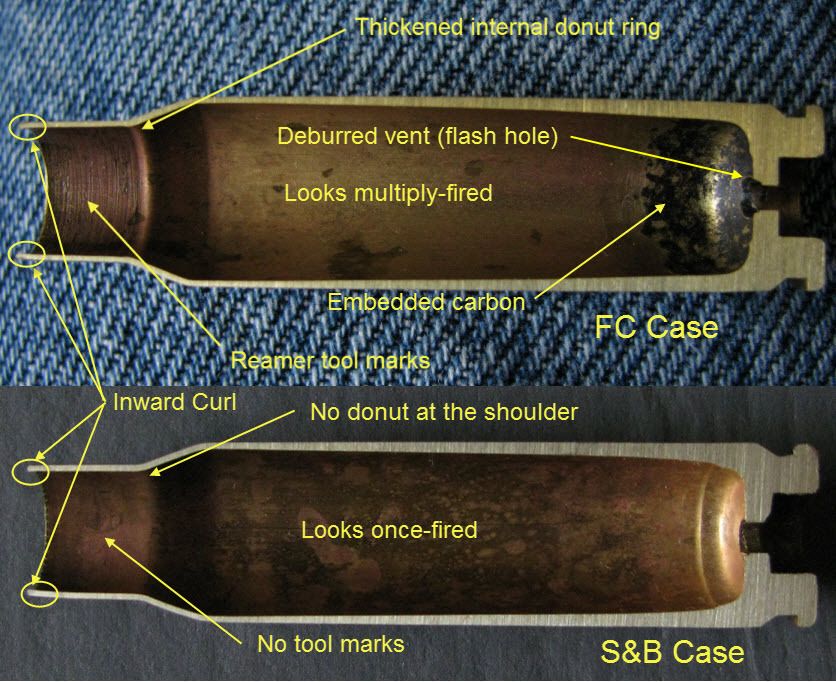

Below is an image of .308 case, the bottom one a newly fired case and the upper one well-used. Both show the little bit of inward curl at the mouth.

So How does a cannelure affect that? My expectation would be that when there is a crimped cannelure, it will delay the start of bypass because the crimped case mouth takes a little more time and effort to lift clear of the bullet, which is probably how it raises start pressure. It would seem likely that as it starts to lift, gas can, indeed, start to bleed through the grooves in the cannelure, so the mouth may not lift quite as far as it does from a smooth bullet surface until after the bullet had moved the cannelure past the mouth, and thus it adds a little drag to the bullet's initial motion. A cast bullet crimp groove would behave no differently. Indeed, I have some jacketed bullets of foreign manufacture that have crimp grooves in them; a sort of toothless cannelure. They are not very accurate, though. It's not easy to avoid distorting a bullet when you roll any kind of groove into it. This is why match bullets don't have cannelures. Though, frankly, the big bullet makers have gotten pretty good at rolling cannelures with minimal distortion, and I've had some very accurate Hornady and Sierra bullets that have cannelures.