Georgiacatweazle,

Below is an illustration of bullet and case parts. It's for rifle, but the terminology still matches. The only point of confusion might be that some cast bullets have what looks like a very shallow boattail, but which is actually called a bevel base just for making seating into brass easier.

Load data:

Given similar bullet materials and weights, but different shapes, in general, the thing you would match pressure with is match the seating depth based on an ideal length case so the calculation sets the distance from the bottom of the bullet to the bottom of the case. But if the HP is a jacketed bullet and the 200 grain RN is a cast bullet, jacketed and cast bullet data often don't mix, and you'll want to find some data for a cast 200 grain RN. They need to both be cast or both be jacketed for this to apply:

1.) Find seating depth for load you want to match from:

Seating Depth = Ideal Case Length + Bullet Length – COL

In your case it would be:

Seating Depth = 0.898" + HP Bullet Length – 1.178"

Once you have that seating depth, figure out a COL for your bullet when it is seated to the same seating depth. This is done by rearranging the formula to solve for COL:

COL = Ideal Case Length + Bullet Length – Seating Depth

In your case it would be:

COL = 0.898" + 200 gn RN shape – HP bullet seating depth from first calculation.

As long as both bullets are cast of same hardness material, that would produce a pretty good pressure match in most circumstances.

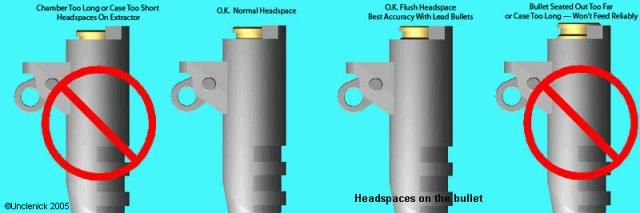

However, all that said, .45 Auto and other short pistol cases often don't have a simple powder capacity relationship because the powder space is so small it is common for the primer to unseat the bullet and push it out against the lands before the powder has time to build pressure well. That means that no matter what seating depth you use, you end up with the same pressure that you get seating as the third drawing from the left of my old illustration shows that Nick CS put up. Since that seating method produces better accuracy and less leading with cast bullets anyway, seating that way makes more sense. The only potential problem with it is if your bullet's nose profile is so long that seating that way causes the cartridges to be too long for the magazine. In that case, use the formula approach.