You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boyd gun stocks?

- Thread starter Chad.C

- Start date

Exceeded my expectations !!!

In the past five years, I have ordered three of their stocks without any issues. ..

Be Safe !!!

For many reasons my measure is that they are the best. I recently bought a thumbhole stock for my Savage-93 and was very pleased with the fit. They exceeded my expectations. .....are they any good

In the past five years, I have ordered three of their stocks without any issues. ..

Be Safe !!!

Boyd's just work !

I have a Boyd's walnut (RIA) sporter on my Yugo M24/47 8mm mauser, and a Boyd's Pepper Laminate (Prairie Hunter) on my Son's Spanish 7mm mauser.

I purchased both stocks unfinished, sanded them myself (180, 240, & 320 grit) and hand rubbed them with Birchwood Casey's Tru Oil (7 coats and 5 coats respectively).

They turned out great and have been in the rain many times with no ill effects.

The guns handle with ease, and are easier to shoot well, in the Boyd's stocks.

They are both over 60 years old, but don't feel that way in those stocks.

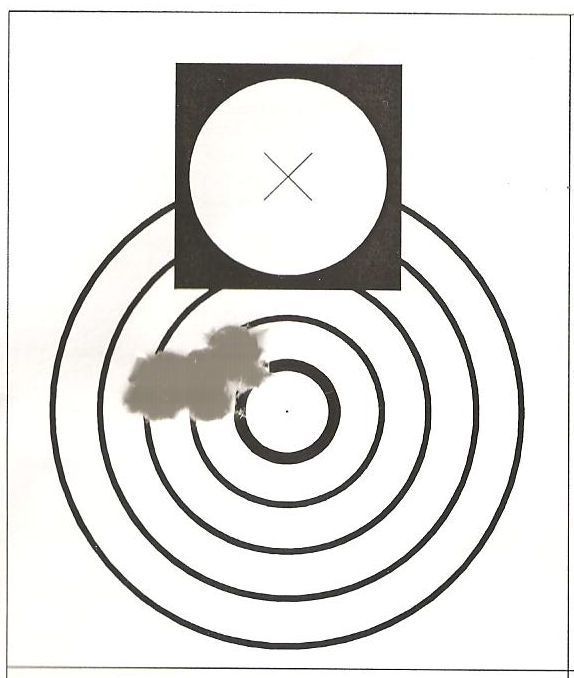

92551 92552

I have a Boyd's walnut (RIA) sporter on my Yugo M24/47 8mm mauser, and a Boyd's Pepper Laminate (Prairie Hunter) on my Son's Spanish 7mm mauser.

I purchased both stocks unfinished, sanded them myself (180, 240, & 320 grit) and hand rubbed them with Birchwood Casey's Tru Oil (7 coats and 5 coats respectively).

They turned out great and have been in the rain many times with no ill effects.

The guns handle with ease, and are easier to shoot well, in the Boyd's stocks.

They are both over 60 years old, but don't feel that way in those stocks.

92551 92552

Attachments

The Boyd's web site sucks if you are searching to see what they have.

10 years ago I encountered a high pressure salesman on the phone there.

But they have a lot of stocks, and the prices are low. They will custom cut for cheap.

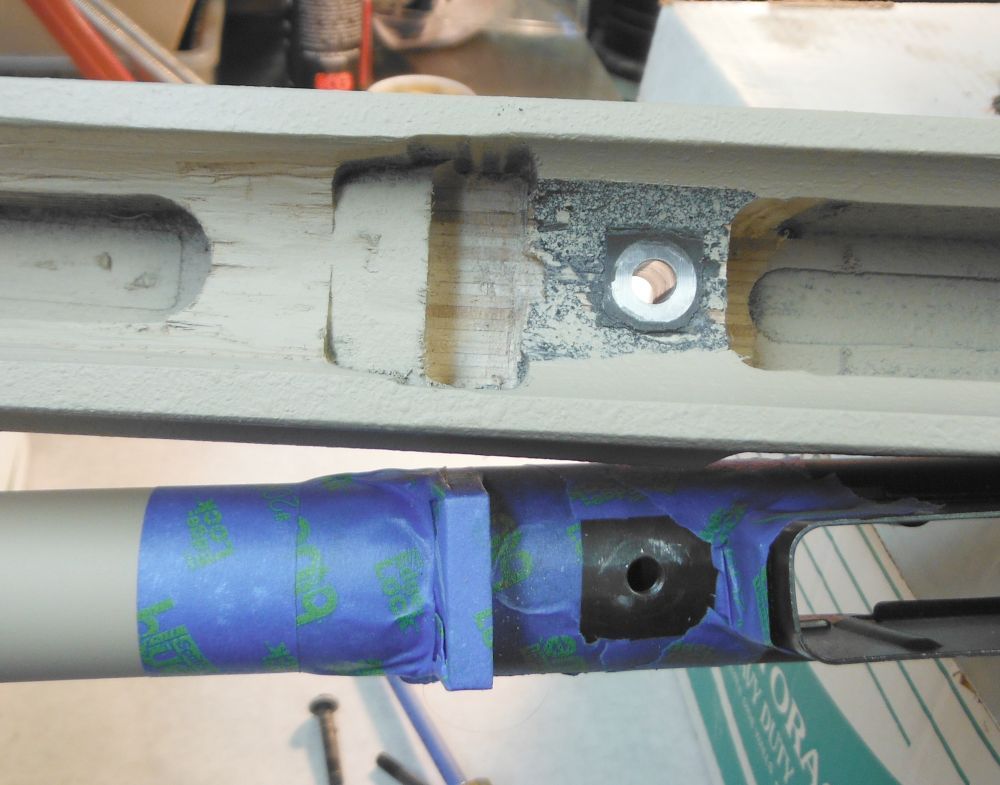

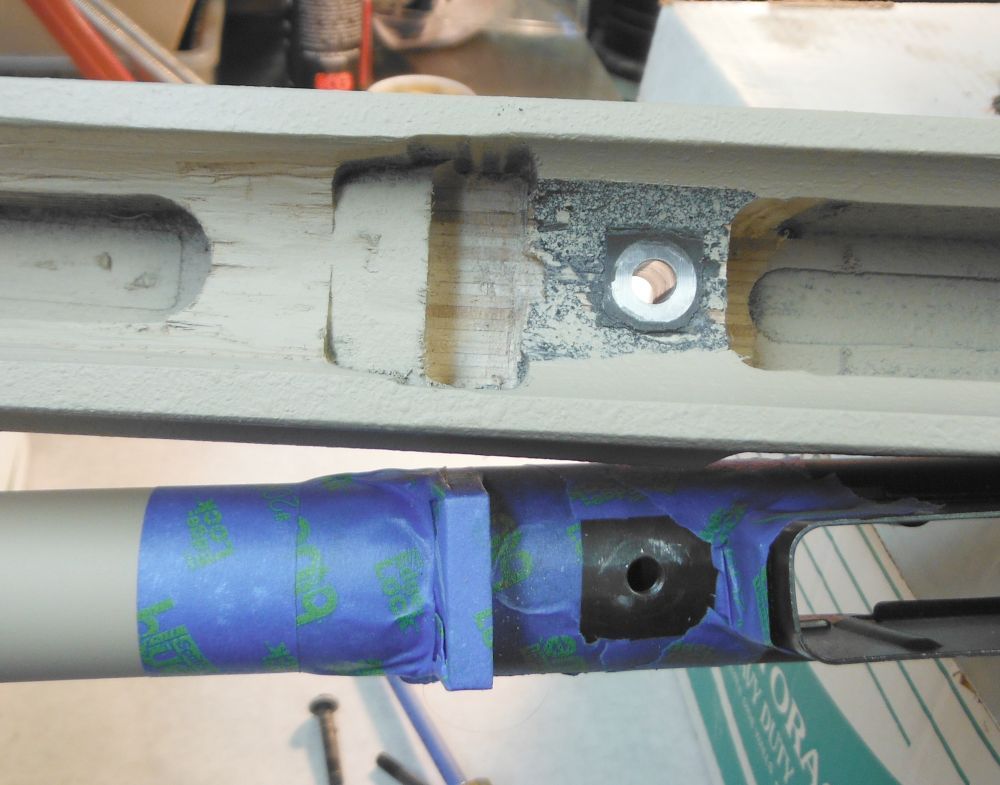

Last month I bedded one, and this is how I did it.

I cut pillars on the lathe from 1/2" aluminum alloy round stock and then mill the ends with a boring head to get a radius that matches the round receiver.

I put the barrelled action upside down in the barrel vise and level it.

I put the pillars on and pre compress them with the action screws.

I set the space between the barrel and stock and between the action and stock with layers of tape.

I put Devcon on the pillars.

I put the stock over the pillared action and wrap surgical cord around them to bind them together.

I level the stock.

After the pillars have cured, I measure the volume of the recoil lug well and the volume of the recoil lug. I calculate how full to fill the recoil lug well with Devcon.

I get the rifle right side up, up in the air, with the recoil lug well filled with the right amount of Devcon, and then I tighten the the action screws.

When done the barreled action only touches the stock at the two pillars and the back of the recoil lug.

The action screws should be such a low compliance connection that they go from first resistance to maximum torque in 10 degrees of rotation.

10 years ago I encountered a high pressure salesman on the phone there.

But they have a lot of stocks, and the prices are low. They will custom cut for cheap.

Last month I bedded one, and this is how I did it.

I cut pillars on the lathe from 1/2" aluminum alloy round stock and then mill the ends with a boring head to get a radius that matches the round receiver.

I put the barrelled action upside down in the barrel vise and level it.

I put the pillars on and pre compress them with the action screws.

I set the space between the barrel and stock and between the action and stock with layers of tape.

I put Devcon on the pillars.

I put the stock over the pillared action and wrap surgical cord around them to bind them together.

I level the stock.

After the pillars have cured, I measure the volume of the recoil lug well and the volume of the recoil lug. I calculate how full to fill the recoil lug well with Devcon.

I get the rifle right side up, up in the air, with the recoil lug well filled with the right amount of Devcon, and then I tighten the the action screws.

When done the barreled action only touches the stock at the two pillars and the back of the recoil lug.

The action screws should be such a low compliance connection that they go from first resistance to maximum torque in 10 degrees of rotation.

Great value. They use Rutland Strataply laminates (I buy my blanks from them) and they're high quality. But like any other stock (and laminates are more stable than hardwoods), I'd recommend bedding at least the recoil lug to maximize longevity- and improve consistency/accuracy of the stock.

Keep in mind that for older rifles, esp. milsurps where receiver dimensions can vary final fitting of the action to the stock can be from mild to wild- and their disclaimers say so.

Keep in mind that for older rifles, esp. milsurps where receiver dimensions can vary final fitting of the action to the stock can be from mild to wild- and their disclaimers say so.

Huffmanite

New member

Have bought maybe 5 stocks from Boyds last 4 or so years and they were decent. Mind you some were their unilet stocks that had no inletting, but of the ones that were inletted for a particular kind of action, they were decently done. Mine were all walnut stocks, no laminated ones.

I wouldn't hesitate buying a Boyd's stock, providing I did not want a stock with a top grade/showroom piece of wood.

I wouldn't hesitate buying a Boyd's stock, providing I did not want a stock with a top grade/showroom piece of wood.

Just installed one last night...

So yeah, I like them.

I have a Savage Axis in .223, and the worst part of the gun has always been the stock. Well, Boyds' began offering stock for the Axis in mid-October, and I ordered immediately.

I did have some fitting issues to deal with as they accidentally sent me a prototype from the first run, but they dealt with it incredibly well and there are not enough good things to say about their customer service. I have Boyds' stocks on 3 of my rifles, and like them all. For the money, I do not think they can be beat. I plan to glass bed this new one when my range closes for January and February.

For pics, go here (not allowed to post the same pictures in different threads) - post #35.

So yeah, I like them.

I have a Savage Axis in .223, and the worst part of the gun has always been the stock. Well, Boyds' began offering stock for the Axis in mid-October, and I ordered immediately.

I did have some fitting issues to deal with as they accidentally sent me a prototype from the first run, but they dealt with it incredibly well and there are not enough good things to say about their customer service. I have Boyds' stocks on 3 of my rifles, and like them all. For the money, I do not think they can be beat. I plan to glass bed this new one when my range closes for January and February.

For pics, go here (not allowed to post the same pictures in different threads) - post #35.