Details

The 742 and similar models that had the multi-rows of small locking lugs on the bolt would peen a series of matching dents into the rails that can be directly seen without disassembly by shining a light through the bolt handle slot in the side of the frame while the bolt is forward. It is possible to make a more thorough examination when the mechanism is completely disassembled, but I can make a reliable call on expectations by examining the areas visible with the bolt closed and open.

Pulling the magazine and trigger assembly allows viewing the peen marks in the typical multiple battered areas. The barrel and bolt do not need to be removed if doing only an inspection of the battered areas- you just have to fight the action spring with that tiny bolt handle with the sharp edges against your one finger- use a rag, if necessary.

Peening evidence will be visible directly along the rail top surface on the far inside of the receiver in the indicated area. All will exhibit some peening, but heavy peening will have edges that stick up past the dents about as high as the dents are deep.

At that level of deformity, bolt troubles of remaining locked back are common, and any goof that tries to smooooooth off the dent/burred areas usually makes no difference of how well the gun functions due to the lack of bolt guide surface, since it has been ground or filed away. You basically trade one version of a "wedgie" for another, and removed metal has no way of being put back into place.

I have been able to do some special refit of parts and reforming of the metal to improve reliability. The last example repaired here was able to run multiple magazines without a hiccup during test fire for confirmation. I call that "returned to usefulness".

Kirby

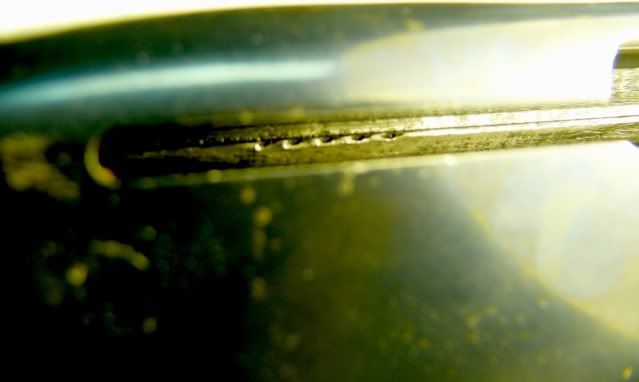

This is the view (previously mentioned) through the bolt handle slot in the side of the frame. Notice that the peen dents have no metal protruding up above the level of the rail- thus denoting that there has been filing etc. in an attempt to smooth the burred areas.

Here is another rail that has evidently been smoothed by filing and polishing etc. After all of that rework, the action still had unresolved issues that I later did mitigate, for the time being. No repair is forever, but can make a useful lifespan if no excess shooting like plinking is done with these rifles. The mechanisms were going to have a long life if only used for hunting and the testing necessary to ensure sight alignment and modest levels of practice. Many of the.308 and 30/06 rifles had batches of military surplus run through them and accelerated the process of deterioration that would have taken a normal lifetime and compressed that level of shooting into a couple of years (or less).