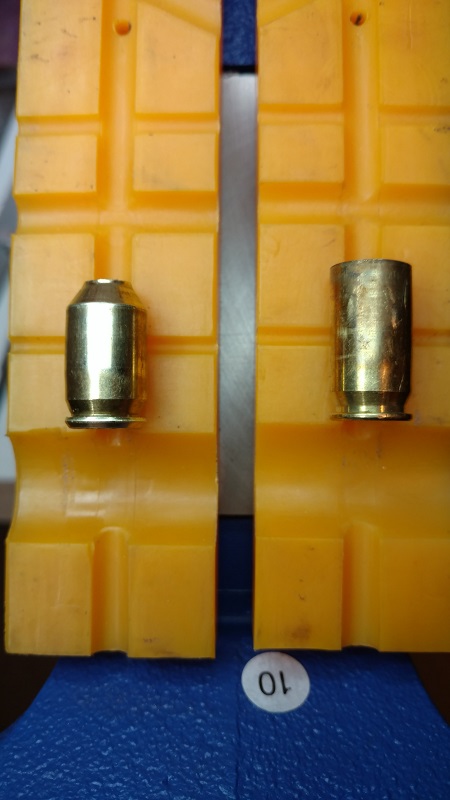

My cell phone camera is crap - but had the digital out this morning and grabbed a better picture of my swaged JHP .40 S&W projectiles.

This started life as 2 fired 9mm shell casings.

These were them polished, annealed to a cherry red and polished again.

Then a 165 grain 9mm lead core was inserted.

Then one was initially formed with a creasing die to add 6 creases.

Then both were pushed through a BT sniper nose forming die on a walnut hill swaging press to form both the hollow point cavity and the ogive nose of the projectile. This step also expands the lead fully into the 9MM shell and expands the whole thing to appx .4015 in size. WARNING - I broke a rockchucker in this step- highly recommend only doing this on a press rated for SWAGING - never a standard bullet press.

And the end result are .40 S&W JHP with an average weight of 187gr.

Now besides producing a pretty good JHP, these have one other use - If you fire cast lead rounds - especially through a Glock factory barrel - and have leading. The extractor ring on the 9mm casing does a magnificent job removing any lead fowling and buildup in the barrel.

As for the end result on the creased JHP - test firings have the creased JHP's breaking up into up to 8 pieces upon impact - the 6 creased lead pieces of the top point, then the main body of lead in the round, and then the jacket which tends to daisy out into a jagged flower of brass. This appears to be a low penetration stopping round that sheds a lot of its energy breaking up on impact. It's just the sort of performance I look for in a JHP.

This started life as 2 fired 9mm shell casings.

These were them polished, annealed to a cherry red and polished again.

Then a 165 grain 9mm lead core was inserted.

Then one was initially formed with a creasing die to add 6 creases.

Then both were pushed through a BT sniper nose forming die on a walnut hill swaging press to form both the hollow point cavity and the ogive nose of the projectile. This step also expands the lead fully into the 9MM shell and expands the whole thing to appx .4015 in size. WARNING - I broke a rockchucker in this step- highly recommend only doing this on a press rated for SWAGING - never a standard bullet press.

And the end result are .40 S&W JHP with an average weight of 187gr.

Now besides producing a pretty good JHP, these have one other use - If you fire cast lead rounds - especially through a Glock factory barrel - and have leading. The extractor ring on the 9mm casing does a magnificent job removing any lead fowling and buildup in the barrel.

As for the end result on the creased JHP - test firings have the creased JHP's breaking up into up to 8 pieces upon impact - the 6 creased lead pieces of the top point, then the main body of lead in the round, and then the jacket which tends to daisy out into a jagged flower of brass. This appears to be a low penetration stopping round that sheds a lot of its energy breaking up on impact. It's just the sort of performance I look for in a JHP.