You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Belgian Gun Blue ---

- Thread starter Prince55

- Start date

Dixie Gunsmithing

Moderator Emeritus

Really, most clean water will work, such as well or spring water, since it is there to heat the part, allowing the bluing chemical to work when applied, and forms the blue/rust after placing the part back back into the water, then removed again for carding.

Some say you can use Hereter's formula out of the bottle, cold, on heated parts. Others say it should be transfered into a glass bottle, to be heated. A glass bluing bottle should be placed where it will stay heated, suspended off the side of tank, and hanging in the water, to where you can get a swab into it, to apply to the polished steel, after heating.

You should also clean the polished steel parts with something like Brownell's Dicro-Clean 909, or equivalent, before bluing. Do not handle the parts, unless with clean gloves, afterwards.

Art Isaacson, I think, is making the old Herter's bluing formula. It comes in a plastic bottle, which means you'll have to transfer it to a small 2 oz. or so glass bottle, if you want to use it heated. Art used to have a video on how to use this, but I don't see it listed now.

Some say you can use Hereter's formula out of the bottle, cold, on heated parts. Others say it should be transfered into a glass bottle, to be heated. A glass bluing bottle should be placed where it will stay heated, suspended off the side of tank, and hanging in the water, to where you can get a swab into it, to apply to the polished steel, after heating.

You should also clean the polished steel parts with something like Brownell's Dicro-Clean 909, or equivalent, before bluing. Do not handle the parts, unless with clean gloves, afterwards.

Art Isaacson, I think, is making the old Herter's bluing formula. It comes in a plastic bottle, which means you'll have to transfer it to a small 2 oz. or so glass bottle, if you want to use it heated. Art used to have a video on how to use this, but I don't see it listed now.

I have always used distilled water. It is not expensive and I think the minerals and/or chemicals found in tap water could affect the blue. I can't say they do, because I have never wanted to take a chance on using other than distilled water.

(FWIW, those "spring" waters often are nothing more than the city tap water in places that sound good. It might have come from some "pure clear spring" to begin with, but when it was bottled, it came out of the pipe.)

Jim

(FWIW, those "spring" waters often are nothing more than the city tap water in places that sound good. It might have come from some "pure clear spring" to begin with, but when it was bottled, it came out of the pipe.)

Jim

Dixie Gunsmithing

Moderator Emeritus

Jim is correct, bottled spring water is about all tap water from a cities supply. (I think it's the biggest rip-off since selling air). When I say spring, I mean an actual natural spring on your own property, or other, such as a farm, etc., and running into a cistern.

If Art is making it to the original Herter's formula, it should work with clean well/spring water, as that is what was used back then, by many. However, if you have a hard water well, I'm not sure how it will react.

Before dishing out a lot of dough on distilled water, (around $10-$14 a case, or 6 gallons), heat some water on the stove, in an old pot, and try bluing a small piece of polished and cleaned steel. If it works, then your water is okay to use. If you don't have hard water, and don't have to use a filter, then you're probably okay.

If Art is making it to the original Herter's formula, it should work with clean well/spring water, as that is what was used back then, by many. However, if you have a hard water well, I'm not sure how it will react.

Before dishing out a lot of dough on distilled water, (around $10-$14 a case, or 6 gallons), heat some water on the stove, in an old pot, and try bluing a small piece of polished and cleaned steel. If it works, then your water is okay to use. If you don't have hard water, and don't have to use a filter, then you're probably okay.

Last edited:

Jim Watson

New member

Rain water used to be the standard source of clean water.

These days maybe after a long rain to scrub some of the pollution out of the air.

These days maybe after a long rain to scrub some of the pollution out of the air.

Bill DeShivs

New member

I have used tap water here, but our water is about the best in the country.

I really don't think distilled water costs $10-$14 a gallon. Ms. Debbie buys it for me to do plating with, and I'm pretty sure she would have noticed $14 water!

Dixie- are you using Perrier for your bluing, or was your decimal point off?

I really don't think distilled water costs $10-$14 a gallon. Ms. Debbie buys it for me to do plating with, and I'm pretty sure she would have noticed $14 water!

Dixie- are you using Perrier for your bluing, or was your decimal point off?

Dixie Gunsmithing

Moderator Emeritus

Sorry about that, I should have written per case. There are 6 gallons in a case. Though that doesn't count the shipping on around 50+ pounds, by ordering from Amazon, etc. if you order it.

You could try purified water, too, it is much less.

I edited the post to reflect the case price.

You could try purified water, too, it is much less.

I edited the post to reflect the case price.

Dixie Gunsmithing

Moderator Emeritus

Jim, I though about Rain water, and it may work now. To me, it should be better, since the so called acid rain, produced by burning coal, is nowhere like it was in the 1970's and earlier. Hardly any housing or factories are heated by coal now, and the power plants are now scrubbed, more now than then, so any acid content should be much less.

Bill. you're correct, as you need distilled for plating, as there's no way around it, that I know of. Undistilled water will mess up a plating bath, and it's bad to use in lead-acid batteries too. I used the price for a case, and typed gallon. I had in mind enough to fill a tank, which will consume about 4-5 gallons. I need to start rereading what I type better. Thanks for catching that.

Bill. you're correct, as you need distilled for plating, as there's no way around it, that I know of. Undistilled water will mess up a plating bath, and it's bad to use in lead-acid batteries too. I used the price for a case, and typed gallon. I had in mind enough to fill a tank, which will consume about 4-5 gallons. I need to start rereading what I type better. Thanks for catching that.

Last edited:

Dixie Gunsmithing

Moderator Emeritus

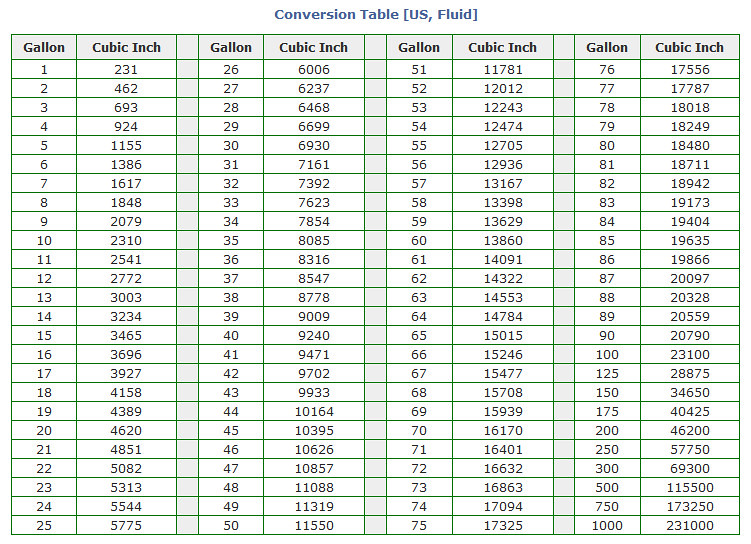

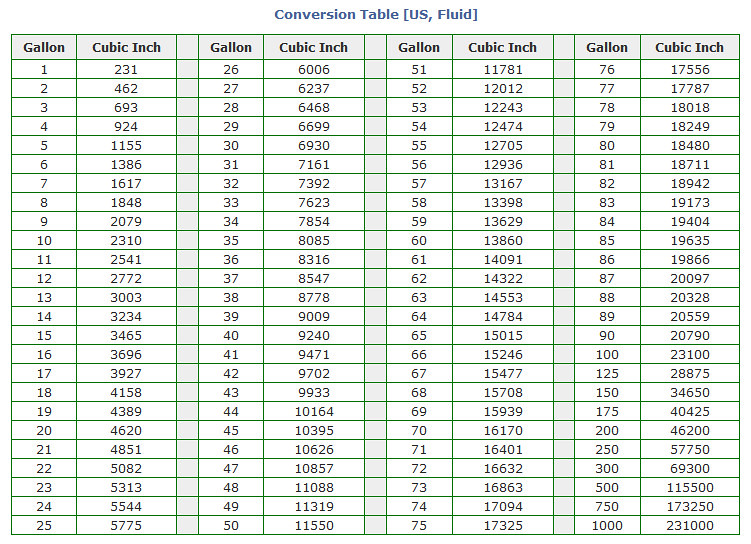

Gallons to Cubic Inches

I thought I'd add this gallons to cu. in. conversion chart, for those who need to fill a certain size tank, etc., with water for bluing.

US, Fluid by Will Matney, on Flickr

US, Fluid by Will Matney, on Flickr

Also, one can divide by 231, if the cu. in. of the tank is known. If you have a rectangular 6" x 6" x 40" tank, and you want to fill it to within 1" of the top, you would have 6" x 5" x 40" = 1220 cu. in. Then, 1200 / 231 = 5.19 Gal.

For a round container, using the example of a 12" pot or cooker, that is 6" deep, and you want to fill it to 5", you would use the formula: radius squared x pi, or 6" radius x 6" x pi (or 3.14159) = 113 inches for the pots area, in sq. inches, then multiply that by the depth of 5", equals 565 cu. in. 565 / 231 = 2.44 Gallons

I thought I'd add this gallons to cu. in. conversion chart, for those who need to fill a certain size tank, etc., with water for bluing.

US, Fluid by Will Matney, on Flickr

US, Fluid by Will Matney, on FlickrAlso, one can divide by 231, if the cu. in. of the tank is known. If you have a rectangular 6" x 6" x 40" tank, and you want to fill it to within 1" of the top, you would have 6" x 5" x 40" = 1220 cu. in. Then, 1200 / 231 = 5.19 Gal.

For a round container, using the example of a 12" pot or cooker, that is 6" deep, and you want to fill it to 5", you would use the formula: radius squared x pi, or 6" radius x 6" x pi (or 3.14159) = 113 inches for the pots area, in sq. inches, then multiply that by the depth of 5", equals 565 cu. in. 565 / 231 = 2.44 Gallons

Winchester 75 Target trigger guard ---

I've had trouble getting a decent finish on a Winchester model 75

trigger guard. Seems like it might be alloyed with nickel or other.

I finally just gave up a few months ago. I might try again.

It kept turning out mostly gray / brown.

Thanks for the tips

I've had trouble getting a decent finish on a Winchester model 75

trigger guard. Seems like it might be alloyed with nickel or other.

I finally just gave up a few months ago. I might try again.

It kept turning out mostly gray / brown.

Thanks for the tips

Dixie Gunsmithing

Moderator Emeritus

I have a 75, and the guard looks to be just a stamped sheet metal guard, and I'd guess it's out of something like A569-A1011, or maybe A-36 steel, though both are about the same, steel wise, except how it's rolled. Either ought to blue well, as it does in a caustic bath.

How many coats did you apply, and card between with steel wool, or a carding wheel? It might take 5-6+ applications, with reheating and carding in between, for it to blacken.

It is possible for them to have used an iron flat, which will turn a brown to a redish-purple, when blued in an unmodified caustic solution, but this isn't the same as the Herter's chemicals. I use a modified caustic, which wouldn't show that color, only a blue-black, so I may have missed what it's made of. I've only used hot water bluing for double barrel sets over the ribs soldering.

How many coats did you apply, and card between with steel wool, or a carding wheel? It might take 5-6+ applications, with reheating and carding in between, for it to blacken.

It is possible for them to have used an iron flat, which will turn a brown to a redish-purple, when blued in an unmodified caustic solution, but this isn't the same as the Herter's chemicals. I use a modified caustic, which wouldn't show that color, only a blue-black, so I may have missed what it's made of. I've only used hot water bluing for double barrel sets over the ribs soldering.

Even if it comes directly from a flowing, clear spring, in the remote mountains, water may be full of minerals that will mess up a bluing job. Some spring water is hard as heck, depending on the type of rock it has flowed through.

I still suggest distilled water, but those who have had good success with their local well or city water will certainly save money.

Jim

I still suggest distilled water, but those who have had good success with their local well or city water will certainly save money.

Jim

FrankenMauser

New member

I would stick with distilled water, as well. ...At least in my part of the country.

I can get 5 gallons for $4.50 or less. Last year, for a camping trip, I picked up 9 gallons for just over $7 (four 2.25 gallon jugs at $1.79 apiece). I went for 'drinking water' but the distilled was cheaper...

My grandfather's place is in the foothills of the mountains, here in Southern Idaho. He got EXTREMELY lucky when he had to put in a new well, and tapped right into an underground river. (The rest of the valley below him is tapped into the aquifer that's just 40 feet underground and contaminated with fertilizer, PCBs, and cow crap.)

He's got crisp, clean, delicious, flowing water, straight from the bedrock of the mountains.

...And it's the hardest water I've ever seen. He averages maybe two years per water heater, before the liners are caked with minerals and have to be replaced. His plumbing (vales, elbows, and faucets in particular) has to be chiseled clean of the deposits every 6-8 months. He's on his fourth pressure tank in 40 years. I lost count of the number of pumps he's had to put in (though part of that is due to the deep well). And, he passes massive kidney stones on a regular basis.

Spring water, it is. But, suitable for rust conversion on a firearm? ...Not in my opinion.

I can get 5 gallons for $4.50 or less. Last year, for a camping trip, I picked up 9 gallons for just over $7 (four 2.25 gallon jugs at $1.79 apiece). I went for 'drinking water' but the distilled was cheaper...

Yep....Even if it comes directly from a flowing, clear spring, in the remote mountains, water may be full of minerals that will mess up a bluing job. Some spring water is hard as heck, depending on the type of rock it has flowed through.

My grandfather's place is in the foothills of the mountains, here in Southern Idaho. He got EXTREMELY lucky when he had to put in a new well, and tapped right into an underground river. (The rest of the valley below him is tapped into the aquifer that's just 40 feet underground and contaminated with fertilizer, PCBs, and cow crap.)

He's got crisp, clean, delicious, flowing water, straight from the bedrock of the mountains.

...And it's the hardest water I've ever seen. He averages maybe two years per water heater, before the liners are caked with minerals and have to be replaced. His plumbing (vales, elbows, and faucets in particular) has to be chiseled clean of the deposits every 6-8 months. He's on his fourth pressure tank in 40 years. I lost count of the number of pumps he's had to put in (though part of that is due to the deep well). And, he passes massive kidney stones on a regular basis.

Spring water, it is. But, suitable for rust conversion on a firearm? ...Not in my opinion.

Dixie Gunsmithing

Moderator Emeritus

Jim, FrankenMauser, yes, spring or well water will have some minerals in it, and not all is hard water, but it's the same water that was used with Herter's bluing back when it was still made by Herter's. If I remember correctly, distilled water wasn't even mentioned back then (See the Brownell's Kinks books).

Myself, and another Gunsmith, (where I apprenticed), used well water in both hot water bluing, (Herter's and Dicropan), and caustic bluing, (Oxynate 7), and we didn't have a problem, before 1987. That was when I was still in Ky., and had soft well water. (I'm not sure what the water was at McCarty's). Here, all that's available is city water, and you have to use something else for hot water bluing.

I used to use Lesage spring water, for hot water bluing, that was actually real spring water, and bottled just across the river in WV. They went out of business, (a law passed making them chlorinate it), and now I have to use distilled. I may try the purified water that they have available, as it is supposed to be filtered, however, I don't know if there's any chlorine or fluorine in it. If there is, those two and acid don't play well together.

One thing I noticed, though it is about caustic bluing, is that on the AGI video about it, Gene Shuey uses tap water for the rinse tanks. This setup drags that water into the bluing. I think he states that he uses the same water to control the caustic bath, too. He doesn't say what his water supply is, whether well or city. Of course, I do the same, and have never had a problem, and it is city tap water. Then again, this is a totally different chemical process, when compared to an acid based bluing.

Myself, and another Gunsmith, (where I apprenticed), used well water in both hot water bluing, (Herter's and Dicropan), and caustic bluing, (Oxynate 7), and we didn't have a problem, before 1987. That was when I was still in Ky., and had soft well water. (I'm not sure what the water was at McCarty's). Here, all that's available is city water, and you have to use something else for hot water bluing.

I used to use Lesage spring water, for hot water bluing, that was actually real spring water, and bottled just across the river in WV. They went out of business, (a law passed making them chlorinate it), and now I have to use distilled. I may try the purified water that they have available, as it is supposed to be filtered, however, I don't know if there's any chlorine or fluorine in it. If there is, those two and acid don't play well together.

One thing I noticed, though it is about caustic bluing, is that on the AGI video about it, Gene Shuey uses tap water for the rinse tanks. This setup drags that water into the bluing. I think he states that he uses the same water to control the caustic bath, too. He doesn't say what his water supply is, whether well or city. Of course, I do the same, and have never had a problem, and it is city tap water. Then again, this is a totally different chemical process, when compared to an acid based bluing.

Gunplummer

New member

I lived in a place named Limeport for years. Take it from there. I used well water for rust bluing and never had a problem. I did have some problems with the rust action of different formulas I used. The last time I blued (8-9 years ago), Brownell's was making "Brownell's Classic Rust Blue". I do not know if they still sell this, but it is a very aggressive rust agent. You actually can "Burn" the parts if you let them rust too long between boils. As said before, metal content will affect color, but so will the bluing you are using. Brownell's really gives you a dark, blue-black color quicker than a lot of others.

Dixie Gunsmithing

Moderator Emeritus

Gunplummer,

They still make it. I was looking at the MSDS sheet on it, and it is Nitric Acid based. The first original hot water rust blue was Nitric Acid, and a handful of nails dissolved in it. Brownell's version has a bit more in it.

The Brownell's version has Nitric Acid, Ferric Nitrate, Ferric Chloride, and Hydrogen Chloride. Ferric Nitrate is the most concentrated chemical in it, and I'd say, both Ferric's take place of the nails. They do have an odd range on the percentages of each, that vary a good bit. The Nitric Acid is from 2.5% to 10%.

http://www.brownells.com/gunsmith-tools-supplies/metal-prep-coloring/metal-bluing/specialty-bluing-chemicals/classic-rust-blue-prod22820.aspx

They still make it. I was looking at the MSDS sheet on it, and it is Nitric Acid based. The first original hot water rust blue was Nitric Acid, and a handful of nails dissolved in it. Brownell's version has a bit more in it.

The Brownell's version has Nitric Acid, Ferric Nitrate, Ferric Chloride, and Hydrogen Chloride. Ferric Nitrate is the most concentrated chemical in it, and I'd say, both Ferric's take place of the nails. They do have an odd range on the percentages of each, that vary a good bit. The Nitric Acid is from 2.5% to 10%.

http://www.brownells.com/gunsmith-tools-supplies/metal-prep-coloring/metal-bluing/specialty-bluing-chemicals/classic-rust-blue-prod22820.aspx