One is a Weatherby Vanguard in .30-06. It shot excellent groups with the original synthetic stock. After replacing it with a Boyd's walnut stock it shot the same load into similar groups to the same point of impact at 100 yards. I didn't even have to adjust the scope. Very surprising

1) In your opinion, will bedding the actions of these guns provide a noticeable benefit?

You did not mention group size nor show any pictures of the groups. Assuming that your groups are 1.25" or less, I would not monkey around with the Boyd's stock. Actually, I probably would monkey around with the Boyd's stock, but having gone down that path before, with a hunting rifle, and I had mixed results. My rifle was a 30-06 M700 and taking the thing out of the factory Tupperware stock and bedding it in a laminated wood stock, my groups were not sufficiently small to have made a difference.

My experience with a M700 in 6.5 Swede was different. I conducted load development for M700 classic in 6.5 Swede and found the thing was not necessarily a tack driver. At 100 yards it did shoot under 2”, which I consider perfectly acceptable for deer hunting. If the rifle shoots 2 MOA, then it will hit within four inches at 200 yards, six inches at 300 yards. That is plenty good, considering that I don’t hold much better with a lightweight rifle off the bench.

The 6.5 Swede action was in a wooden factory stock. For this rifle, and someone else confirmed their rifle was similar, Remington created a raised area in the barrel channel which created a pressure point. I like free floated barrels. When a barrel heats up it will expand. If there is a pressure point, or a bearing point on the barrel, as the barrel expands, the pressure against the barrel changes. This will cause a change in a point of impact. Not only did the stock have this raised factory pressure point, the barrel rubbed against the side of the barrel channel.

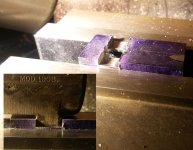

So with stock channel tools, I scraped the barrel channel, removing the pressure point, and created a clearance so the barrel no longer touched the left side of the barrel channel. I suspect the left side of the barrel touching the stock created a lot of side to side movements. But not all. If the recoil lug is free to slide around in the stock, the action will shift during recoil.

I “pillar” bedded creating columns of Bisonite, and then I routed a humongous amount of wood forward of the magazine recess, and filled that with Bisonite. The final bedding looks awful, with voids, and it is not completely filled out around the recoil lug recess. But I was tired and grumpy and wanted to shoot my rifle, so I put it back together and took it to the range.

Anyway, just bedding this rifle changed its group size considerably. These lightweight rifles are hard to shoot, they are twitchy, they kick hard, and they are very sensitive to stock weld and shooting position. Still, this rifle shot close to 1 MOA which is excellent for a deer rifle.

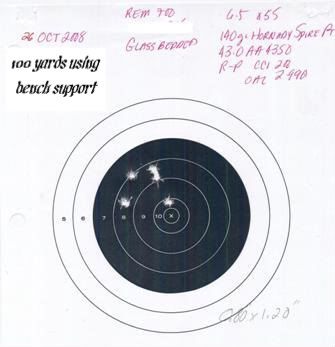

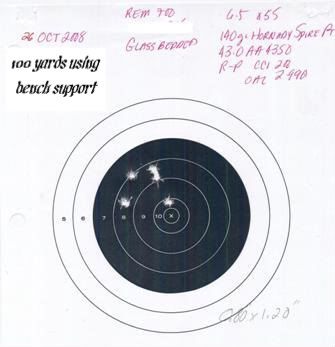

I have couple of "before glassbedding" targets. Everything is at 100 yards. If you notice the wide horizontal dispersion with 140 SMK’s. Sierra match bullets are in a word, superb. In a match barrel they will shoot bug hole groups. This side to side movement indicated to me that something was wrong with the bedding. The action, or the barrel was moving left and right in the stock.

In my opinion it shot much better. This target was fired fast, about five shots under a minute, maybe two. I racked the bolt and shot if the crosshairs looked good. The barrel was hot enough to be uncomfortable to touch.

2) I still have the original tupperware for the Vanguard - just because - if I bed it in the Boyd's stock, would you recommend bedding it in the plastic stock, too

I have not tried bedding a Tupperware stock and don't know if there would be complications. If the rifle shoots well in the Boyd's, I would not mess with the factory Tupperware stock. The primary reason is that I would hold on to it and see if I could sell it, or keep it in case I wanted to sell the Vanguard. Shooters don't want to buy a messed up stock, and having to grind out someone else's epoxy will make the stock hard to sell. And then, having a factory original rifle, one not showing any bubba bedding (some of my bedding jobs are horrible looking) would make the whole rifle easier to sell.

Bed only if you are having accuracy problems or just want a project. And do it in the Boyd's aftermarket stock only.