The rifle is a Remington 700 LTR 308 Cal. When removing the barrel and action from the stock, I noticed horizontal rub marks on the sides of the barrel between the lug and the action screw. Which matches lines on the aluminum bedding block. I was thinking of slightly grinding some of the bedding away and bedding with Devcon 10110 plastic steel puddy. Has anyone out there bed a HS precision stock or had this problem. Chris

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bed a HS Precision Stock

- Thread starter cw308

- Start date

Same here. I've got the same contact indicators on my HS precision PS012 stock with a 700 SPS. I've read where some people have skim bedded these by roughing up the aluminum and back filling, but from what I've seen on mine, a 1/2 moa rifle doesn't need fixing. Leave it be unless you've got problems.

Harry Bonar

New member

bedding

Sir;

I ALWAYS bed even the aluminum bedding blocks with Brownells steel bed after roughing up the recoil lug srea, Aluminum blocks are not always perfect.

Harry B.

Sir;

I ALWAYS bed even the aluminum bedding blocks with Brownells steel bed after roughing up the recoil lug srea, Aluminum blocks are not always perfect.

Harry B.

bedding

Sir;

I ALWAYS bed even the aluminum bedding blocks with Brownells steel bed after roughing up the recoil lug srea, Aluminum blocks are not always perfect.

Harry B.

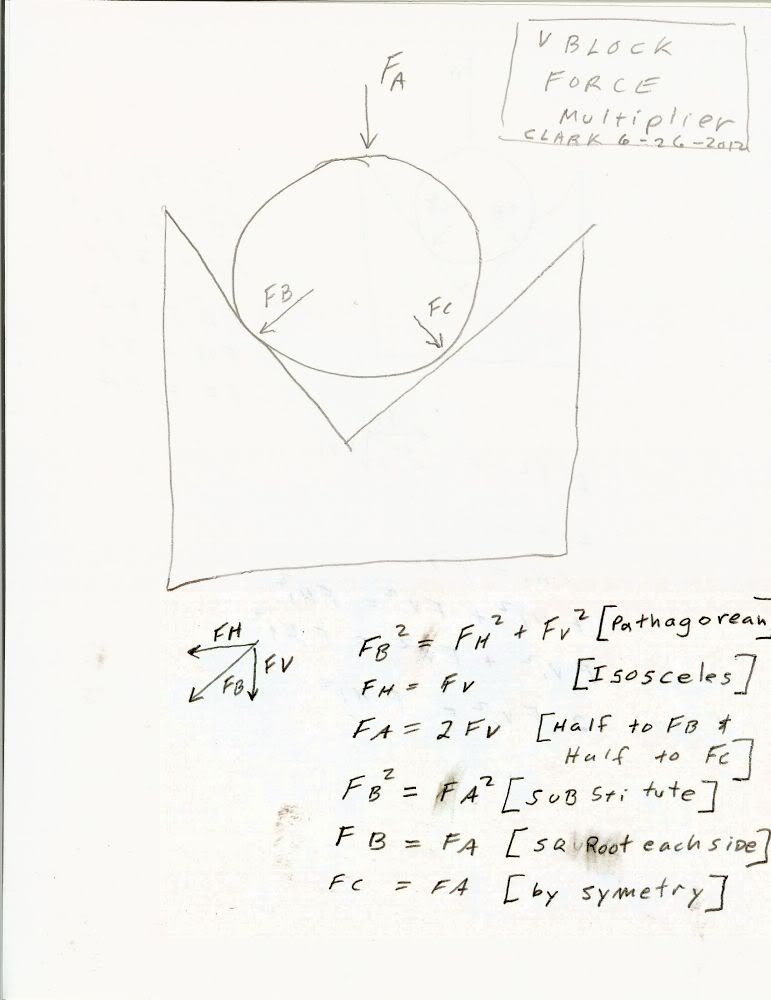

A cylinder [receiver] forced into V blocks, gets that force multiplied.

Remember calculating vectors in statics in freshman engineering?

If there is bedding interfering, some of the force multiplication may be lost.

If all of it is lost, and the cylinder is forced into a mating concave cylindrical bedding, we have one of the worst connections possible, with side to side rocking getting leverage to pull against the action screws.

We can only get so much axial tension on the action screws, and we want all the stiffness we can get out it.

I test the quality of the bedding job by grasping the stock wrist with one hand, smacking the barrel with the heel of the other hand and listing for vibration. Any buzz means there is interference. A long sustained pure tone means I have achieved my goal, an action to stock fastening that is so low compliance that the stock mass will be in a consistent recoil reaction before bullet escapement.

I often think that the goals of bedding get lost after people are distracted by the ritual of the process and the appearance when complete.

Hah! I scoff at this 'math'! What a poor excuse for tried and true stock bedding voodoo juju!!

Just kidding of course! All you need to do for an HS stock is make sure the action screws are torqued to 65 in/lbs. I make sure to tighten the front screw first then the rear. My Rem PSS sits in an HS and properly torqued it shoots like a laser

Just kidding of course! All you need to do for an HS stock is make sure the action screws are torqued to 65 in/lbs. I make sure to tighten the front screw first then the rear. My Rem PSS sits in an HS and properly torqued it shoots like a laser

Hmmmm, magical V-blocks . . . .I did some math, and the 90 degree V block doubles the forces.

Curious what conspired with the OP's project. I too have an H-S stock that i had the same thoughts about, not grinding out any of the original aluminum block surface in my case but just bedding the lug recess.

My gun sits upside down as we speak in the curing stage.

While i was already bedding the lug recess, i decided to scratch up the front block's surface and apply the Devcon there as well, why not, its right next to the lug recess i was bedding- might as well. I used the smallest carving attachment of my Dremel set at a slow speed and let it bounce up and down on the entire block surface to rough the aluminum up real good. Then, i went on and drilled some 1/16" shallow dimples evenly spread across the surface of the same area. Since i still want to be in contact with the original surface up front and did not bed the rear at all, i torqued the action to the stock immediately before the Devcon had time to begin to cure.

I dont believe i altered the original state too much and hope this will benefit to further support and stabilize my action in this cool new stock i bought.

My gun sits upside down as we speak in the curing stage.

While i was already bedding the lug recess, i decided to scratch up the front block's surface and apply the Devcon there as well, why not, its right next to the lug recess i was bedding- might as well. I used the smallest carving attachment of my Dremel set at a slow speed and let it bounce up and down on the entire block surface to rough the aluminum up real good. Then, i went on and drilled some 1/16" shallow dimples evenly spread across the surface of the same area. Since i still want to be in contact with the original surface up front and did not bed the rear at all, i torqued the action to the stock immediately before the Devcon had time to begin to cure.

I dont believe i altered the original state too much and hope this will benefit to further support and stabilize my action in this cool new stock i bought.

Scorch

I did some math, and the 90 degree V block doubles the forces.

Hmmmm, magical V-blocks . . . .

http://en.wikipedia.org/wiki/Simple_machine

Lever

Wheel and axle

Pulley

Inclined plane

Wedge

Screw

Think of it as a double wedgie.

Have not worked with the Rem action,but my M-70 has an HS Precision stock.

Before I considered mucking with the bedding block,I might try coating the reciever with a thin coat of prussian blue and put it together with the screws just snugged up to see how it settles in.If I had a high spot bearing hard I might scrape it in.

Before doing anything,may I ask,how does it shoot?I know you saw little marks,but,how does it shoot?

Before I considered mucking with the bedding block,I might try coating the reciever with a thin coat of prussian blue and put it together with the screws just snugged up to see how it settles in.If I had a high spot bearing hard I might scrape it in.

Before doing anything,may I ask,how does it shoot?I know you saw little marks,but,how does it shoot?

Shoots great. Turned out real well. I still have the original lines from the block coming through the Devcon so i know i didnt alter the actions original contact position to the stock . The Devcon did a great job filling in the lug recess and the center section of the block that is lower than the area of the two lines so that the entire underside of the barrel section behind the lug has good positive contact. I used a razor blade and Dremel to carve the edges of the Devcon so that its foot print is the same as the surface area of the front block section. I had to sand in front of the lug a little so that the Devcon did not touch the barrel. I only have contact at the lug and block. With the factory barrel and action, i dont know if it truely helped but it makes me think so anyway. I believe drilling dimples and removing a slight ammount of the center of the block is key to the Devcon being thick enough to not break up as well as making sure to not sand/gring away any of the area where the two lines show the original surface contact. The Devcon filled in the front screw hole of the stock aroung the screw a little so i used a drill bit to enlarge the hole so that the screw/stock does not bind.