locknloader

New member

Can anyone shed some light on the basics of powder burn rates and how that comes into play when reloading (or point me to some good reading on the subject).

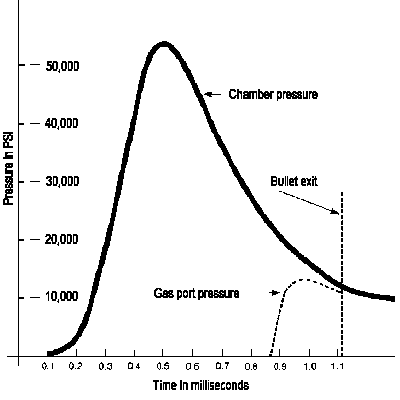

The very basic understanding i have so far is that fast burning powders reach peak pressure more quickly, have more of a "snap" than "push" recoil feel.

I am having a hard time finding some good information about how burn rate comes into play when selecting a powder for a given round. I have only been finding general statements like "dont use a fast powder, pressure jumps too quickly" or people will just randomly suggest a powder, then when i look it up i notice the burn rate is damn close to the one someone else said not to use, -CENSORED--CENSORED--CENSORED-!!!

I'd like to have a good enough understanding of the critical data points of a powder so i can apply that towards load development, and not use general statements made by others to guide my decision.

I am mainly interested in 9mm and 40cal right now, but i think it's necessary to include other rounds like 45 in the discussion because i believe that's a lower pressure round and the 9/40 are higher pressure ones?

Sorry for my ignorance but gota start somewhere!

The very basic understanding i have so far is that fast burning powders reach peak pressure more quickly, have more of a "snap" than "push" recoil feel.

I am having a hard time finding some good information about how burn rate comes into play when selecting a powder for a given round. I have only been finding general statements like "dont use a fast powder, pressure jumps too quickly" or people will just randomly suggest a powder, then when i look it up i notice the burn rate is damn close to the one someone else said not to use, -CENSORED--CENSORED--CENSORED-!!!

I'd like to have a good enough understanding of the critical data points of a powder so i can apply that towards load development, and not use general statements made by others to guide my decision.

I am mainly interested in 9mm and 40cal right now, but i think it's necessary to include other rounds like 45 in the discussion because i believe that's a lower pressure round and the 9/40 are higher pressure ones?

Sorry for my ignorance but gota start somewhere!