You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone have a Lee Loader instructions in ANY gauge?

- Thread starter UK2TX

- Start date

Lee has all their manuals online. You can find one for the Load All here:

http://www.leeprecision.com/instruct/index.html

Bob

http://www.leeprecision.com/instruct/index.html

Bob

Hello Bobshouse,

Thanks for the reply, unfortunately I was looking for the instructions for the original Lee Loader not the Load-All, and thanks to Jack R-NJ I'm soon to be sorted.

This is the email I got from Lee when I asked them about it:

-----Original Message-----

From: info@leeprecision.com [mailto:info@leeprecision.com]

Sent: Tuesday, February 05, 2002 6:04 AM

Subject: Re: Lee Loader 10ga shotgun instruction set

The Target Model Reloader, Lee Loader for shot shells, Auto Prime with threaded shell holder was made by Lee Custom Engineering. For the whole story, read Richard Lee's article in Handloader's Digest, 17 th. ed., etc.)

Lee Custom has been out of business for a number of years and Lee Precision does not make parts for those tools.

Thanks for the reply, unfortunately I was looking for the instructions for the original Lee Loader not the Load-All, and thanks to Jack R-NJ I'm soon to be sorted.

This is the email I got from Lee when I asked them about it:

-----Original Message-----

From: info@leeprecision.com [mailto:info@leeprecision.com]

Sent: Tuesday, February 05, 2002 6:04 AM

Subject: Re: Lee Loader 10ga shotgun instruction set

The Target Model Reloader, Lee Loader for shot shells, Auto Prime with threaded shell holder was made by Lee Custom Engineering. For the whole story, read Richard Lee's article in Handloader's Digest, 17 th. ed., etc.)

Lee Custom has been out of business for a number of years and Lee Precision does not make parts for those tools.

Precision33

Inactive

Did UK2TX actually post the instructions for the Lee Loader? I have a 12ga. set in perfect cond., but no instruction sheet. Sure would help!!

Lee loader Instructions

I have Lee Loaders in 12,16, 20 and .410. It may take a couple of days but I will scan and post when I get back home.

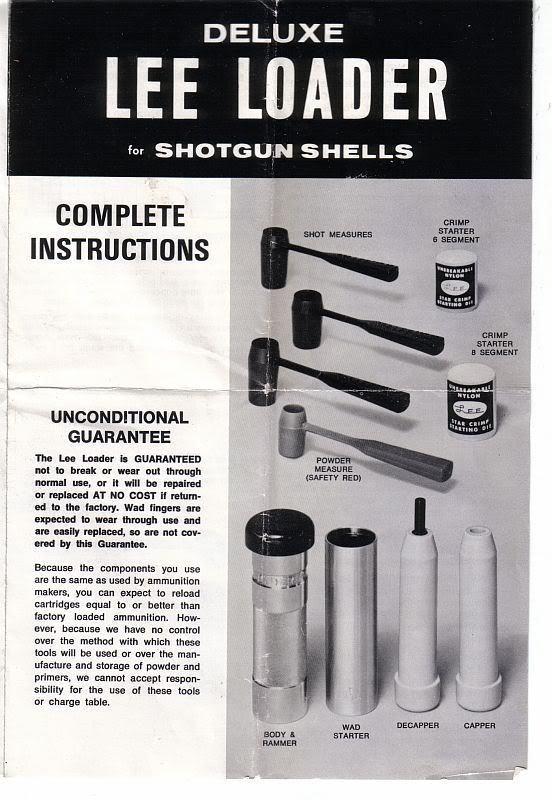

Basically - the box contains a steel loading body with a steel rammer nested inside. There is a decapper (a steel rod with a punch at one end), a capper (a steel rod with a hole in one end), an adjustable shot measure and a plastic powder dipper embossed 190.

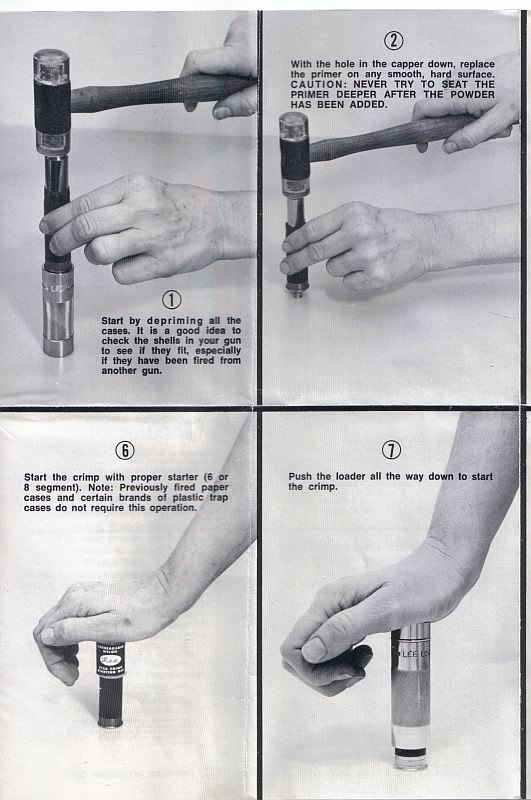

1- you deprime all your hulls first. Place the hull in to open end of the loading body that has the split ring nearest. It should sit on a little flange. Put the decapping rod into the hull and hit it with a mallet. This should drive the primer out.

2- reprime the cases. Put the rounded top rammer back into the loading body. Place a 209 primer on top of the rammer's head. Place a deprimed hull onto the primer. Place the capping rod, hole end first into the hull. Tap the rod so that the hull seats down onto the primer, flush.

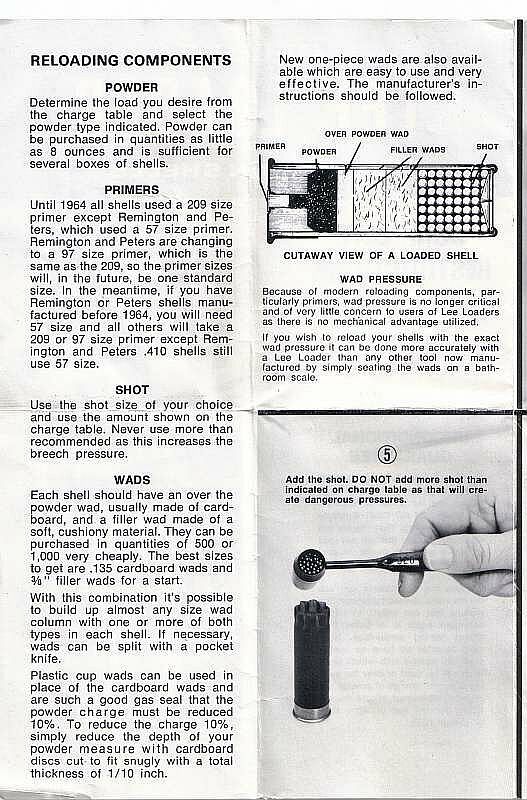

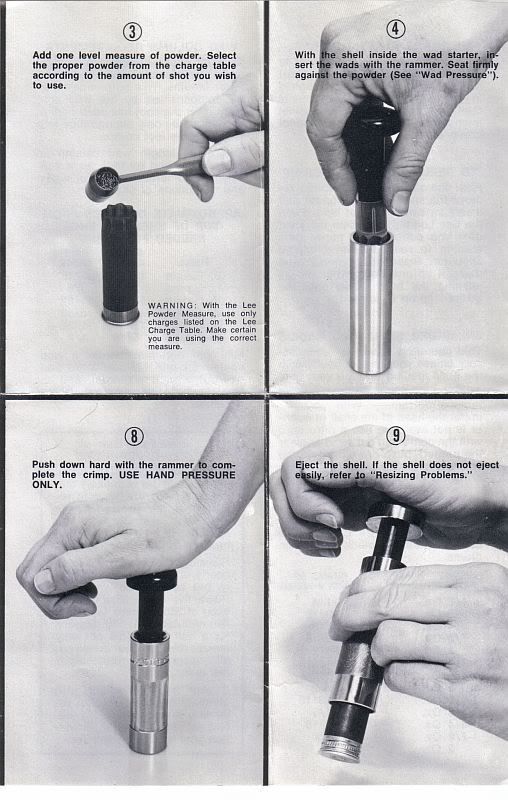

3- Add one level powder measure of powder (the safest powder used and available today is Red Dot. But the 190 dipper is likely to throw too much; it is about the same size as the Lee 3.1cc dipper. You only need about 18 grains of Red Dot or 23 grains of Unique). Place the loading body onto the hull split ring end up.

4- Insert your wad. Seat it with the rammer.

5- Drop in one ounce and one eighth of shot.

6- Push the loading body all the way on to the hull to start the crimp.

7- Insert the rammer into the loading body from the still open end of that body and push down hard to close the crimp.

8 - pick up the shell, load body and rammer and, pushing on the rammer, eject the shell.

The new yellow plastic Lee dipper at 2.5 cc will give you the load that you need for ReD Dot and Unique.

Pete

I have Lee Loaders in 12,16, 20 and .410. It may take a couple of days but I will scan and post when I get back home.

Basically - the box contains a steel loading body with a steel rammer nested inside. There is a decapper (a steel rod with a punch at one end), a capper (a steel rod with a hole in one end), an adjustable shot measure and a plastic powder dipper embossed 190.

1- you deprime all your hulls first. Place the hull in to open end of the loading body that has the split ring nearest. It should sit on a little flange. Put the decapping rod into the hull and hit it with a mallet. This should drive the primer out.

2- reprime the cases. Put the rounded top rammer back into the loading body. Place a 209 primer on top of the rammer's head. Place a deprimed hull onto the primer. Place the capping rod, hole end first into the hull. Tap the rod so that the hull seats down onto the primer, flush.

3- Add one level powder measure of powder (the safest powder used and available today is Red Dot. But the 190 dipper is likely to throw too much; it is about the same size as the Lee 3.1cc dipper. You only need about 18 grains of Red Dot or 23 grains of Unique). Place the loading body onto the hull split ring end up.

4- Insert your wad. Seat it with the rammer.

5- Drop in one ounce and one eighth of shot.

6- Push the loading body all the way on to the hull to start the crimp.

7- Insert the rammer into the loading body from the still open end of that body and push down hard to close the crimp.

8 - pick up the shell, load body and rammer and, pushing on the rammer, eject the shell.

The new yellow plastic Lee dipper at 2.5 cc will give you the load that you need for ReD Dot and Unique.

Pete

Last edited:

oneounceload

Moderator

I had one of those in the pre-internet days of yore - pretty straightforward - work from left to right......

Then I graduated to MEC single stage and then to progressives.......and it goes on and on........

Then I graduated to MEC single stage and then to progressives.......and it goes on and on........

Precision33

Inactive

darkgael, Thanks for taking the time to write out the instructions! I will enjoy making a box of reloads the old fashioned way!!

oneounceload said:I had one of those in the pre-internet days of yore - pretty straightforward - work from left to right......

Then I graduated to MEC single stage and then to progressives.......and it goes on and on….….

Wow! Déjà vu all over, again. The same sequence started for me in the late 60s. Went the same route with reloading metallics, too -- LEE to Dillon.

fancy

Crimp starter? Wad starter?

What will they think of next? That must be one of the "new" kits.

What size is the dipper in that set? What powders did Lee cite? Shot weight?

These are so handy that I wonder why Lee stopped production. The .410 sets fetch a premium on Ebay.

Pete

Crimp starter? Wad starter?

What will they think of next? That must be one of the "new" kits.

What size is the dipper in that set? What powders did Lee cite? Shot weight?

These are so handy that I wonder why Lee stopped production. The .410 sets fetch a premium on Ebay.

Pete

oneounceload

Moderator

For the work involved in making one shell I could load up a half box on my lowly MEC Jr. single stage.............