The one I borrow from work is bigger, and about $15,000

The hand held unit they use in the field has two lasers, the most accurate reading is between the lasers, the display shows the highest temp detected.

Admittedly, I didn't think about the refresh rate, the expensive unit is real time, I haven't played with the hand held enough to tell if it's real time or a series of time spaced images.

I found out that Templiq is a little off, depending on how much thinner used, humidity, the time from apply to heating, the age of the bottle, etc.

So I also used a thermocouple when gas heating.

The metal thermocouple runs into trouble when induction heating, the Stainless probe heats faster than the brass,

That's why I used infrared as my verifying check of the Templiq.

My 'Last Word' has always been the end result, the Rockwell test.

The process to get that last result takes different routes, gas or induction, high temps and faster times or lower temps and longer times, etc.

I *Wish* they would sell a 800*F unit for the same price!

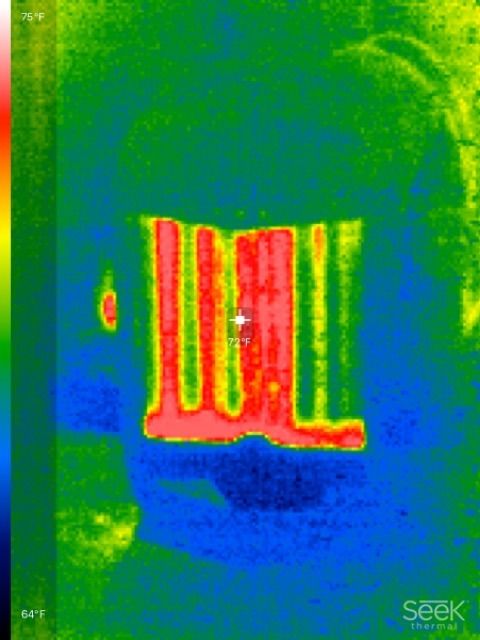

As for application, if you are doing gas, 750*F & 800*F in the neck if you are 'Fast' cooking.

Marking the outside of the case exposes the Templiq to direct flame heat, so you CAN use Templiq to see how far down the heat reaches,

But you can NOT use it on the outside of neck/shoulder to tell when the brass reaches target temp because of direct flame exposure.

I do the 800*F stripe to tell if the case overheated.

This is what tipped me to mouth overheating.

Let me know I needed to heat the case (side) a little lower down to keep the mouth from overheating before the shoulder reached target temp.

That same test let me know the mouth needs to protrude slightly op/out of the annealing coil.

Since induction heats the brass from within, and the mouth is the thinnest part of the case there is less brass to react with the induction, so it doesn't fry brass like gas will,

But I was still finding some signs of overheating when the power got cranked up.

The 'Easiest' solution was to lower the coil a little on the case and the overheating signs immedately went away.

When induction annealing things get a little more simple with Templiq because you can apply to the outside of the case neck/shoulder.

I find with my fat fingers and less than X-ray vision painting the inside of a .22 case neck is a pain in the butt!

I'm still waiting for evolution to give me that magnified vision & third arm with super steady hand...

Until then I make due with magnifier and tiny art store paint brushes.