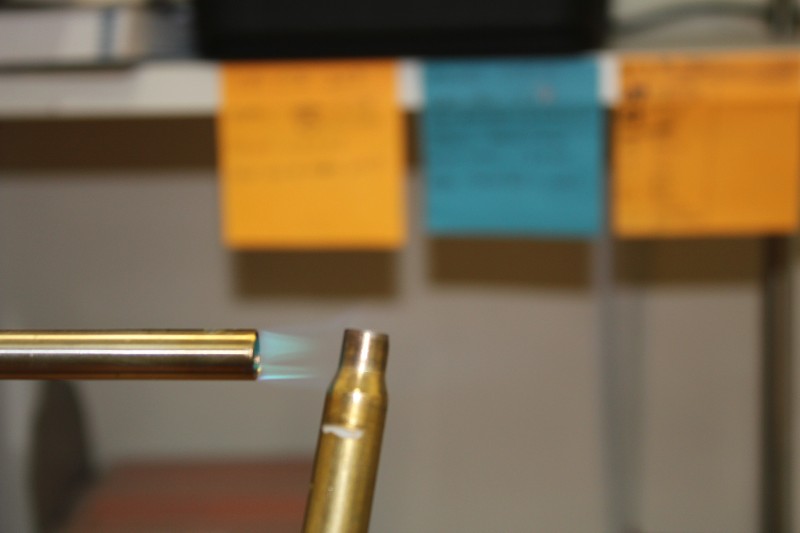

I have a few thousand "twice fired" .223 cases to anneal. I picked up a Giraud tool annealing machine a few months ago and did some initial testing with some junk cases and 750 degree (green) TempilLaq.

It seems most of info and YouTube videos on the Intertubes concerning annealing is wrong: Lots of people saying TempiLaq turns black when it reaches temperature (and they put it on the outside of the case mouth, right in the flame), or heat the brass 'til it's cherry red and "temper" it with a cold water quench, etc...

I went to the TempiLaq site and they have a very nice video of a flat piece of metal sitting in a very well lit oven. There's some TemiLaq on top. When the metal reaches the right temp, the TempiLaq liquifies and puddles. No glowing metal or black TempiLaq here.

So after setting up my machine and running about a hundred junk cases through, I determined that there is no way I can see TempiLaq liquify on the inside of a .223 case mouth while it's rotating in a flame.

Plan "B" was to compare case necks with TempiLaq that had heated and cooled down, to cases that had not been heated to see if I could see signs of spreading or movement of the green stuff that would indicate it went liquid at some point: No dice there either.

So on to plan "C"... I ordered an infra-red thermometer from Amazon. It's got a pair of LED laser pointers that are supposed to indicate how wide of an area the thermometer is reading. They converge at about 27 inches from the lens of the thermometer. I'm hoping at that distance the thing will be reading an area slightly smaller than my case neck.

I'm not one to trust a new piece of gear until it's proven. I have concerns that reading the case mouth while it's in the flame could induce errors. I don't have anything to calibrate this to, so I'm looking for a way to at least verify that I'm in the ballpark (plan "D"?), and not getting the necks too soft.

A friend of mine says he anneals in the dark and stops as soon as the mouth just begins to glow (very) dull red. He's a pretty good shooter but I have no idea what his metallurgy skills might be. I know cherry red is too hot but I don't know what kind of "glow" would be close to 750.

So what kind of glow (if any) would be close 750?

Alternatively, is there a way to test case neck "softness" post annealing? I've seen the advice about squeezing cases with pliers and trying to feel differences but I'm looking for something more objective than "feeling".

It seems most of info and YouTube videos on the Intertubes concerning annealing is wrong: Lots of people saying TempiLaq turns black when it reaches temperature (and they put it on the outside of the case mouth, right in the flame), or heat the brass 'til it's cherry red and "temper" it with a cold water quench, etc...

I went to the TempiLaq site and they have a very nice video of a flat piece of metal sitting in a very well lit oven. There's some TemiLaq on top. When the metal reaches the right temp, the TempiLaq liquifies and puddles. No glowing metal or black TempiLaq here.

So after setting up my machine and running about a hundred junk cases through, I determined that there is no way I can see TempiLaq liquify on the inside of a .223 case mouth while it's rotating in a flame.

Plan "B" was to compare case necks with TempiLaq that had heated and cooled down, to cases that had not been heated to see if I could see signs of spreading or movement of the green stuff that would indicate it went liquid at some point: No dice there either.

So on to plan "C"... I ordered an infra-red thermometer from Amazon. It's got a pair of LED laser pointers that are supposed to indicate how wide of an area the thermometer is reading. They converge at about 27 inches from the lens of the thermometer. I'm hoping at that distance the thing will be reading an area slightly smaller than my case neck.

I'm not one to trust a new piece of gear until it's proven. I have concerns that reading the case mouth while it's in the flame could induce errors. I don't have anything to calibrate this to, so I'm looking for a way to at least verify that I'm in the ballpark (plan "D"?), and not getting the necks too soft.

A friend of mine says he anneals in the dark and stops as soon as the mouth just begins to glow (very) dull red. He's a pretty good shooter but I have no idea what his metallurgy skills might be. I know cherry red is too hot but I don't know what kind of "glow" would be close to 750.

So what kind of glow (if any) would be close 750?

Alternatively, is there a way to test case neck "softness" post annealing? I've seen the advice about squeezing cases with pliers and trying to feel differences but I'm looking for something more objective than "feeling".