If you can change the height of the bench, you first want to decide if you are going to use elevated press mounts or not. Mine don't have them, but I built my benches about 41" tall—about the height of my elbows—as that seems a good height for standing and working. A stool can be added for when you don't wish to stand. I also put down anti-fatigue mats for my feet.

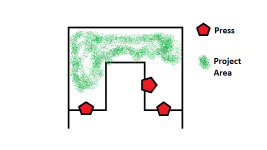

In order to have room left and right of your hands for batch loading rifle cartridges, take a look at

Lee's Benchplate removable press mount. This would let you mount one press in front of you at the bottom of the U-cutout, allowing powder dispensing and staging on either side. The presses you are not using at that moment could store under the bench.

For the last bench I built, I used whiteboard as the top surface. I like having a replaceable surface anyway. I used to use plain 1/8" Masonite board held in place by wood screws, so I could change it out when it got beat up. I switched to the white-coated Masonite (whiteboard) on the last bench build (3 now) so I could write on it with dry-erase pens. This let's me make notes and draw staging areas right on the work surface so I can better keep track of what I'm doing and what stage of the process each component is in. I also put up a whiteboard wall surface behind the bench so I can reach over and write notes or plans on it. I put one of those shallow tool-holder shelves full of different size holes up on the wall to hold the dry-erase pens and screwdrivers and hex wrenches and the like for presses and dies.

I ran a long power strip along the front of the bench that is fed by a voltage regulating transformer and with surge protection, and a small strip is fed from an isolation transformer hooked up to the aforementioned source. I also placed overlapping sheets of aluminum foil under the whiteboard and I have a ground wire going to them. I have grounded spun aluminum reflector lights of the type photographers use. These contain daylight color LED lamps now, but used to have daylight CFL's and a copper screen spanning the aluminum bell opening over each one. This is overkill, but I had the parts and materials lying around and it gives me very clean power and zero interference lighting for my electronic scales. I got a small (9"×12") granite surface plate for the scales to sit on. There is carpet scrap between the stone and the bench to further mitigate vibration.

So, by now you probably figure my bench looks closer to something Dr. Frankenstein might have than a loading bench, but the electricals are pretty much invisible. It's just set up to fight issues I've identified in my place in the past. The amount of extra work wasn't that great and I have something I know always works as well as is practical with electronic scales and measuring gear.

Storage space under the bench is important. I have a Giraud trimmer, boxes of bullets and whatnot under there. Some time back I bought a bunch of the shoe size snap-lid storage boxes from a home supply store and I have a separate one for each chambering I load for. All the dies, gauges or other odds and ends of tooling associated with that chambering go in. They then stack neatly on a shelf under the bench. Bullets and quantities of brass are heavy enough that I prefer not to bend over and reach under the bench for them, so they go on separate shelving adjacent to the bench. If you have separate shelving, you may prefer to keep your second and third presses there for the same reason.