You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.55 accurate load

- Thread starter 225win

- Start date

ligonierbill

New member

I haven't tried SST's, but I can share a couple other 140's. My go to hunting load is a 140 Sierra GameKing over a stout load of Reloder 22. You're shooting a strong rifle, but I don't want to publish an over spec load that someone could get in trouble with. Look at Speer a couple generations back. This goes a bit over 2,700 from my M70 22" and groups under an inch. CCI 200 primer.

The other is a published target load for my 1903 Mauser 96. I managed to shoot a 1 1/4" group with the standard sights with 142 Sierra MatchKings over 44.7 gr Re-22, again with CCI 200.

I have not found a powder that does better than Re-22 with 140's.

The other is a published target load for my 1903 Mauser 96. I managed to shoot a 1 1/4" group with the standard sights with 142 Sierra MatchKings over 44.7 gr Re-22, again with CCI 200.

I have not found a powder that does better than Re-22 with 140's.

I conducted load development in my M700 classic in 6.5 Swede and found the thing was not necessarily a tack driver. At 100 yards it did shoot under 2”, which I consider perfectly acceptable for deer hunting. If the rifle shoots 2 MOA, then it will hit within four inches at 200 yards, six inches at 300 yards. That is plenty good, considering that I don’t hold much better with a lightweight rifle off the bench.

The 6.5 Swede action was in a wooden stock. For this rifle, and someone else confirmed their rifle was similar, Remington created a raised area in the barrel channel which created a pressure point. I like free floated barrels. When a barrel heats up it will expand. If there is a pressure point, or a bearing point on the barrel, as the barrel expands, the pressure against the barrel changes. This will cause a change in a point of impact.

So with stock channel tools, I scraped the barrel channel, removing the pressure point, and created a clearance so the barrel no longer touched the left side of the barrel channel. I suspect the left side of the barrel touching the stock created a lot of side to side movements. But not all. If the recoil lug is free to slide around in the stock, the action will shift during recoil.

I “pillar” bedded creating columns of Bisonite, and then I routed a humongous amount of wood forward of the magazine recess, and filled that with Bisonite. The final bedding looks awful, with voids, and it is not completely filled out around the recoil lug recess. But I was tired and grumpy and wanted to shoot my rifle, so I put it back together and took it to the range.

Anyway, just bedding this rifle changed its group size considerably. These lightweight rifles are hard to shoot, they are twitchy, they kick hard, and they are very sensitive to stock weld and shooting position. Still, this rifle might shoot under 1 MOA, which is excellent for a deer rifle.

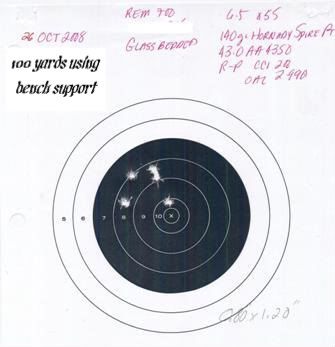

Here is a "before glassbedding" target. Everything is at 100 yards. If you notice the wide horizontal dispersion with 140 SMK’s. Sierra match bullets are in a word, superb. In a match barrel they will shoot bug hole groups. This side to side movement indicated to me that something was wrong with the bedding. The action, or the barrel was moving left and right in the stock.

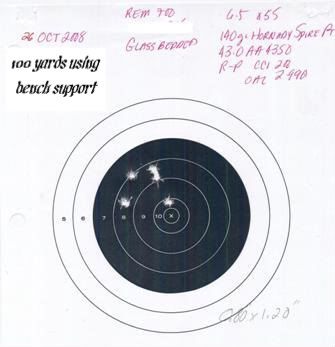

After glassbedding, in my opinion it shot much better. These targets were fired fast, about five shots under a minute, maybe two. I racked the bolt and shot if the crosshairs looked good. The barrel was hot enough to be uncomfortable to touch.

The load for the above target used AA4350. I am of the opinion that any of the 4350's, that is AA4350, IMR 4350, or H4350 will produce outstanding accuracy in this cartridge with a 140 grain bullet. I tested Swedish ball in my M700 and consider the load used on the target to be a close equivalent to ball ammunition. A M700 is built out of better materials than a Swedish service rifle and I could have pushed the velocity up more than service rifle pressures and I would not have had any concerns. However, the load I used shot well and would make an outstanding deer hunting load. I have not seen a reason to change it.

M700 22" Barrel

143 gr Swedish Ball 1986 headstamp

2 Feb 2008 T = 54 °F

Ave Vel =2470

Std Dev =18

ES = 48

High = 2491

Low = 2443

N = 5

140 gr Hornday Spire Point 43.0 grs AA4350 R-P new brass CCI-200 OAL 2.990"

2 Feb 2008 T = 52 °F

Ave Vel =2512

Std Dev =27

ES = 72

High = 2547

Low = 2475

N = 5

The 6.5 Swede action was in a wooden stock. For this rifle, and someone else confirmed their rifle was similar, Remington created a raised area in the barrel channel which created a pressure point. I like free floated barrels. When a barrel heats up it will expand. If there is a pressure point, or a bearing point on the barrel, as the barrel expands, the pressure against the barrel changes. This will cause a change in a point of impact.

So with stock channel tools, I scraped the barrel channel, removing the pressure point, and created a clearance so the barrel no longer touched the left side of the barrel channel. I suspect the left side of the barrel touching the stock created a lot of side to side movements. But not all. If the recoil lug is free to slide around in the stock, the action will shift during recoil.

I “pillar” bedded creating columns of Bisonite, and then I routed a humongous amount of wood forward of the magazine recess, and filled that with Bisonite. The final bedding looks awful, with voids, and it is not completely filled out around the recoil lug recess. But I was tired and grumpy and wanted to shoot my rifle, so I put it back together and took it to the range.

Anyway, just bedding this rifle changed its group size considerably. These lightweight rifles are hard to shoot, they are twitchy, they kick hard, and they are very sensitive to stock weld and shooting position. Still, this rifle might shoot under 1 MOA, which is excellent for a deer rifle.

Here is a "before glassbedding" target. Everything is at 100 yards. If you notice the wide horizontal dispersion with 140 SMK’s. Sierra match bullets are in a word, superb. In a match barrel they will shoot bug hole groups. This side to side movement indicated to me that something was wrong with the bedding. The action, or the barrel was moving left and right in the stock.

After glassbedding, in my opinion it shot much better. These targets were fired fast, about five shots under a minute, maybe two. I racked the bolt and shot if the crosshairs looked good. The barrel was hot enough to be uncomfortable to touch.

The load for the above target used AA4350. I am of the opinion that any of the 4350's, that is AA4350, IMR 4350, or H4350 will produce outstanding accuracy in this cartridge with a 140 grain bullet. I tested Swedish ball in my M700 and consider the load used on the target to be a close equivalent to ball ammunition. A M700 is built out of better materials than a Swedish service rifle and I could have pushed the velocity up more than service rifle pressures and I would not have had any concerns. However, the load I used shot well and would make an outstanding deer hunting load. I have not seen a reason to change it.

M700 22" Barrel

143 gr Swedish Ball 1986 headstamp

2 Feb 2008 T = 54 °F

Ave Vel =2470

Std Dev =18

ES = 48

High = 2491

Low = 2443

N = 5

140 gr Hornday Spire Point 43.0 grs AA4350 R-P new brass CCI-200 OAL 2.990"

2 Feb 2008 T = 52 °F

Ave Vel =2512

Std Dev =27

ES = 72

High = 2547

Low = 2475

N = 5