I have purchased a 6.5-06 about a year ago. I'm currently trying to work up some test loads. Im having problems with the bullets seating in the chamber can anyone give me some ideas as to why when I try and close the bolt with a bullet in the chamber it sticks and I have to force the bolt to close. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5-06 problems

- Thread starter Snyder30

- Start date

Yes I'm reloading them. I've tried trimming the case length back. 2.49 to 2.43 and the case is still to long I'm afraid to go back any farther. I've tried coloring the casing with a Sharpie and looking for scratches and all I see is one little mark on the base of the shoulder.

Coat the rounds with Machinist's Layout Dye. The dried dye will rub-off where contact is being made. If a fired casing will come out of the chamber but will not go back into the chamber when reloaded, then it is something you have done to the casing (too much crimp, bullets seated too far out, etc.).

all I see is one little mark on the base of the shoulder.

I would suggest you avoid crimping the cases. Crimping only requires a hint of effort and then there is that thing with crimping while the bullet is moving down. Lyman claimed crimping is a bad habit, they did that long before the Internet, they claimed crimping reduced bullet hold, after that reloaders invented neck tension and it has made no sense ; since.

F. Guffey

603Country

New member

I had a similar problem with my 223 and the new barrel. Factory loads would chamber (I had to borrow one from a neighbor), but reloads would not chamber. I finally solved my problem by measuring the factory loads and reloads. I found that the thick neck walls of the Lapua brass, with a bullet seated, would not let the round chamber. The new barrel had a real snug match chamber that I was unaware of and had not asked the gunsmith for. I was left with the options of turning necks forever or having the chamber ‘loosened’ a bit. I went with option 2. So, if you can get a factory round (are they easy to buy), compare measurements with your reloads. You’ll find the problem. Of course, finding a factory 223 round may be the easiest thing a fellow can do. Might not be that way with your caliber.

And just last week I went to load and test 60 gr Partitions in that same 223. I started with Nosler’s suggested COAL and they would not chamber. Then I did what I should have done in the first place and measured the chamber for max COAL.

So...measure...

And just last week I went to load and test 60 gr Partitions in that same 223. I started with Nosler’s suggested COAL and they would not chamber. Then I did what I should have done in the first place and measured the chamber for max COAL.

So...measure...

603Country

New member

One other thing...and I have done it...is that you might be causing the case to bulge at the shoulder. Crimping too much (I don’t crimp rifle rounds) or seating flat based bullets (if you haven’t adequately chamfered the case mouth) could cause that. If so, the case will not chamber. You may be doing a tiny bit of that, causing difficulty in chambering. It’s tough to look at a case and tell if you’ve ‘rolled’ the shoulder a bit.

On the other hand, if all you’ve done is resize the case and it won’t chamber. Hmmmm. Ok...back to measuring...

On the other hand, if all you’ve done is resize the case and it won’t chamber. Hmmmm. Ok...back to measuring...

Let me see if I understand.

You have trimmed the case length back,so long cases are probably not the issue.

If you are trying the brass without seating a bullet,crimp,shoulder collapse, and seating depth are eliminated. Don't worry about those for now...maybe later!

Its a 6.5-06. Likely you formed it from something ,like 30-06?

And its a custom barrel/chamber job. You bought the rifle built.

You have a bunch of variables and unknowns.But those can be sorted out.

You might have to learn quite a bit.

IF you have a good riflesmith available(that's a big if) the most straight-line to your solutions would be a Cerro-Safe chamber cast to see what you actually have.

Next best would be if the seller provided a fired case with the rifle that is as fired.

But you may have neither.

Its going to take a process,one variable at a time,and take notes.

You likely are not using factory 6.5-06 brass. How do you get yours?

Are you forming 30-06 brass? If you neck down .044 thousandths,where does the metal go? The neck gets thicker.. Someone mentioned a "tight match chamber"

Maybe. Or your chamber might be the proper size,but with thick necks,your ammo may be oversize.One solution is neck turning.Sort of a PITA,but it can work.

I don't have the drawings handy.But look in load manuals and compare the .270 and 280 .There is some length difference on the .270,but see how the shoulder length dims compare. If you can use .280 brass,you are only necking down .020.Thats less than half the 30-06.I justed checked the .270.It has a longer neck,case length. Its a trim issue.The shoulder is in the same place (OK,1.948 vs 1.949) So you only have to neck down .013 if you use .270 brass. The neck won't thicken enough to cause a problem.

If you are sizing down 30-06,trimming and necking down .270 may solve your problem.( Something you can try,for a test.Your sizing die sizes the outside of the neck down far enough to be slightly undersize.The expander plug upsizes the ID of the neck for proper bullet fit.At that point,if neck thickness is too much,the neck OD will be oversize.So just to try to identify your problem,remove the decap/expander spindle from the die and size a few test pieces.Without the expander,the necks should be small enough.Let me know how that goes)

Next issue,headspace,sizing,shoulder setback.

Order a Wilson (or equivalent) bushing case length gauge. A 30-06 one or a .280 one should work if the don't have a 6.5-06. Now,somebody will disagree. Usually,they don't know how to use a bushing gauge,or the don't bother to maintain a known head clearance. I'll explain later.You decide,listen to them,or me. I don't care. I suggest telling them to ....excuse themselves. The distraction is confusing.

You trimmed and sized your brass.I assume you just bumped the shellholder with the die. Try it in both your new bushing gauge,and your rifle.

If it was tight neck from 30-06 brass,should feel better. Does the bolt close easily? Has the shoulder been setback enough?

Drop it in your gauge. Is it between the high-low limits on the gauge?.

Measure over the case and bushing gauge ,write the number down.

I don't care to write a book here,covering all the possibilities.

When you get this far,tell me the results. We'll take it from there.

A caution note: If,as I suspect,you have a problem with the necks thickening and being tight in the chamber,don't shoot any like that.It can be dangerous.The neck requires room to expand and release the bullet.If it can't,pressures go up.

You have trimmed the case length back,so long cases are probably not the issue.

If you are trying the brass without seating a bullet,crimp,shoulder collapse, and seating depth are eliminated. Don't worry about those for now...maybe later!

Its a 6.5-06. Likely you formed it from something ,like 30-06?

And its a custom barrel/chamber job. You bought the rifle built.

You have a bunch of variables and unknowns.But those can be sorted out.

You might have to learn quite a bit.

IF you have a good riflesmith available(that's a big if) the most straight-line to your solutions would be a Cerro-Safe chamber cast to see what you actually have.

Next best would be if the seller provided a fired case with the rifle that is as fired.

But you may have neither.

Its going to take a process,one variable at a time,and take notes.

You likely are not using factory 6.5-06 brass. How do you get yours?

Are you forming 30-06 brass? If you neck down .044 thousandths,where does the metal go? The neck gets thicker.. Someone mentioned a "tight match chamber"

Maybe. Or your chamber might be the proper size,but with thick necks,your ammo may be oversize.One solution is neck turning.Sort of a PITA,but it can work.

I don't have the drawings handy.But look in load manuals and compare the .270 and 280 .There is some length difference on the .270,but see how the shoulder length dims compare. If you can use .280 brass,you are only necking down .020.Thats less than half the 30-06.I justed checked the .270.It has a longer neck,case length. Its a trim issue.The shoulder is in the same place (OK,1.948 vs 1.949) So you only have to neck down .013 if you use .270 brass. The neck won't thicken enough to cause a problem.

If you are sizing down 30-06,trimming and necking down .270 may solve your problem.( Something you can try,for a test.Your sizing die sizes the outside of the neck down far enough to be slightly undersize.The expander plug upsizes the ID of the neck for proper bullet fit.At that point,if neck thickness is too much,the neck OD will be oversize.So just to try to identify your problem,remove the decap/expander spindle from the die and size a few test pieces.Without the expander,the necks should be small enough.Let me know how that goes)

Next issue,headspace,sizing,shoulder setback.

Order a Wilson (or equivalent) bushing case length gauge. A 30-06 one or a .280 one should work if the don't have a 6.5-06. Now,somebody will disagree. Usually,they don't know how to use a bushing gauge,or the don't bother to maintain a known head clearance. I'll explain later.You decide,listen to them,or me. I don't care. I suggest telling them to ....excuse themselves. The distraction is confusing.

You trimmed and sized your brass.I assume you just bumped the shellholder with the die. Try it in both your new bushing gauge,and your rifle.

If it was tight neck from 30-06 brass,should feel better. Does the bolt close easily? Has the shoulder been setback enough?

Drop it in your gauge. Is it between the high-low limits on the gauge?.

Measure over the case and bushing gauge ,write the number down.

I don't care to write a book here,covering all the possibilities.

When you get this far,tell me the results. We'll take it from there.

A caution note: If,as I suspect,you have a problem with the necks thickening and being tight in the chamber,don't shoot any like that.It can be dangerous.The neck requires room to expand and release the bullet.If it can't,pressures go up.

Last edited:

603Country

New member

Oldscot has a good point. My 220 Swift has a snug chamber, and the RCBS sizing die just barely bumps the shoulder back enough that the reloads will chamber. I ground a touch off of the shell holder in order to size it a bit more.

If you fire a round and then can successfully rechamber the empty case, that’s one significant data point. If you resize that case and now it will not chamber, i’m thinking that your sizing Die is indeed not sizing enough. It’s sizing the body of the case and causing the shoulder to be moved forward, but the Die is not contacting and moving the shoulder back enough.

If you fire a round and then can successfully rechamber the empty case, that’s one significant data point. If you resize that case and now it will not chamber, i’m thinking that your sizing Die is indeed not sizing enough. It’s sizing the body of the case and causing the shoulder to be moved forward, but the Die is not contacting and moving the shoulder back enough.

I've tried using 2506 casings. But I've had more success today with using 270 casings as the measurements for the shoulder are the same. 2506 casings a a weee bit longer from base to start of shoulder. I've resized the 270 casings to 6.5 and turned the neck thickness down. Still not as smooth as I would like it but it's better than yesterday's attempts with the 2506 casings. Does this make sense to anyone

Curious problem. I would be slugging the throat or making a chamber casting to see what the chamber dimensions are like.

Resizing dies are often toleranced to a couple of thousandths. Nothing to write home about, and yours could be a little loose for your chamber. I would take Mr. Guffey's favorite trick, and remove the decapping pin from the sizing die and slip a feeler gauge into the shell holder just under the casehead to force it to be sized down further. You can usually slip a 0.005" gauge in pretty easily. See if that doesn't allow the case to fall into place. You can try different thicknesses of feeler gauge to learn what you really need to get a fit. Once you have that, fire the rounds in that chamber and measure them with a case comparator (improvised as below is fine) so you can tell if your resizing die is failing to return them to that fitting size. If the chamber is tight, it can happen. In that case, you may want to check the needed feeler gauge size again, and, once verifies, have that thickness ground off the mouth of the sizing die so it will work without the feeler gauge.

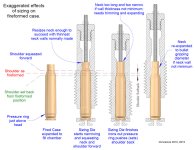

Resizing moves the shoulder forward before moving it back again, so if the shoulder of the die is too far forward, you can wind up with cases too long.

Resizing dies are often toleranced to a couple of thousandths. Nothing to write home about, and yours could be a little loose for your chamber. I would take Mr. Guffey's favorite trick, and remove the decapping pin from the sizing die and slip a feeler gauge into the shell holder just under the casehead to force it to be sized down further. You can usually slip a 0.005" gauge in pretty easily. See if that doesn't allow the case to fall into place. You can try different thicknesses of feeler gauge to learn what you really need to get a fit. Once you have that, fire the rounds in that chamber and measure them with a case comparator (improvised as below is fine) so you can tell if your resizing die is failing to return them to that fitting size. If the chamber is tight, it can happen. In that case, you may want to check the needed feeler gauge size again, and, once verifies, have that thickness ground off the mouth of the sizing die so it will work without the feeler gauge.

Resizing moves the shoulder forward before moving it back again, so if the shoulder of the die is too far forward, you can wind up with cases too long.

Attachments

If it works out that your die is not setting the shoulder back enough,as Unclenick said,having the die ground is an option.I'd have it done in a surface grinder or maybe on a lathe with a toolpost grinder.

There is another way that might be cheaper.Redding sells "Competition Shellholders" which can be had in a shorter deck height.I think you can get as much as .010,in.001 increments.

There is another way that might be cheaper.Redding sells "Competition Shellholders" which can be had in a shorter deck height.I think you can get as much as .010,in.001 increments.

603Country

New member

I just took the low-tech approach and took a little off the top of the shell holder. Probably would be best to do the F Guffey approach and use the feeler gauge first to see how much needs to come off the die or shell holder. I just ground a small amount off the shell holder and sized a case and tried to see if it would fit. I didn’t have the ability to grind the Die accurately and didn’t want to wait for the competition type shellholders.

I've tried using 2506 casings. But I've had more success today with using 270 casings as the measurements for the shoulder are the same.

From the base to the intersection of the shoulder and body should be the same for all three cases. The difference is the distance from the base to the intersection of the neck and shoulder with 270 being the shortest. If 270 is working the best for you, it's another indication your shoulder bump is not enough.

The main reason I suggested using 25-06 brass is because the necks won't get thicker since you're sizing up instead of down.

m&p45acp10+1

New member

Turn the die down until it touches the shell holder. Move the handle so the die can be turned down more. Go down one full turn. With no shell in see if the press will cam over if it does lube and size a case. See if it chambers. If it does problem solved. If not try another half turn down. I have seen this work more times than not.