I am a n00b at this. I loaded about 30 rounds of 45 colt using a modern black powder substitute and had a heck of time getting the fouling out of my barrel.

It reads like I did two things "wrong", just from reading about it.

1. It seems like petrochemicals make BP fouling quite tenacious, I have read a few places now of folks getting thier bore absolutely sparkiling clean, and then taking all the oil off the bore with something like methanol so there is no petro-oil in there to make the fouling sticky. I guess they re-oil their bores with something like rendered bacon fat, thankfully I have some of that.

2. It seems not enough lube makes fouling tenacious, extra lube makes a bit of a mess but cleans up easily.

I have loaded my second batch, but am waiting for warmer weather here. I started with trimmed uniform length brass. Then I measured from the bottom of the case to the rim of the case mouth, and from the base of the bullet to the crimping groove. The substitute I have (I think it is 777, not at home right now to look) wants anywhere from zero free air space to 10% compressed powder charge.

I ended up using a pipe cutter on a spare piece of .45 Colt brass to make a powder measure so I could put the same -volume- of powder in each case.

I also melted up some of my bullet lube and poured it out on a sheet of tim foil on a baking sheet.

There is a bajillion recipes for bullet lube out there. I use 45% beeswax, 45% Crisco and 10% olive oil by weight, and it works good for me down to minus 30dF. Since it is all food grade stuff I can mix it in the kitchen on the regular stove without having to buy a second set of kitchen utensils for my loading bench. I don't know how it will do in summertime heat because I just started using it last fall.

Any road, I let the thin layer of lube cool on the tin foil, and then used another .45 Colt case, this one with the head cut off, as a cookie cutter. I find a .38Spec brass is adequate as a plunger, basically punch the .45 Colt brass into the lube sheet to cut out a cookie, then slide the .38Spec brass head first in from the other end to push the cookie out. My lube cookies are about 0.1" thick.

So I primed the brass, poured in uniform charges of BP substitute, eased a cookie on top of that and then seated my bullet.

I have a hunch I could get away with a lot less sophisticated methodology, but I am willing to put a little effort in the front end to save going through that cleanup from last time again. Also I could get a bigger charge volume if I left the cookie out for perhaps a little more velocity, see cleanup.

I have not yet fooled with a drop tube to help settle my powder charge more densely. I haven't come up with a plunger to manually compress my powder before I seat a bullet on it. I haven't yet fooled with cloth wads. I looked at cloth wads, but for the money they can't possibly be holding very much in the way of lube.

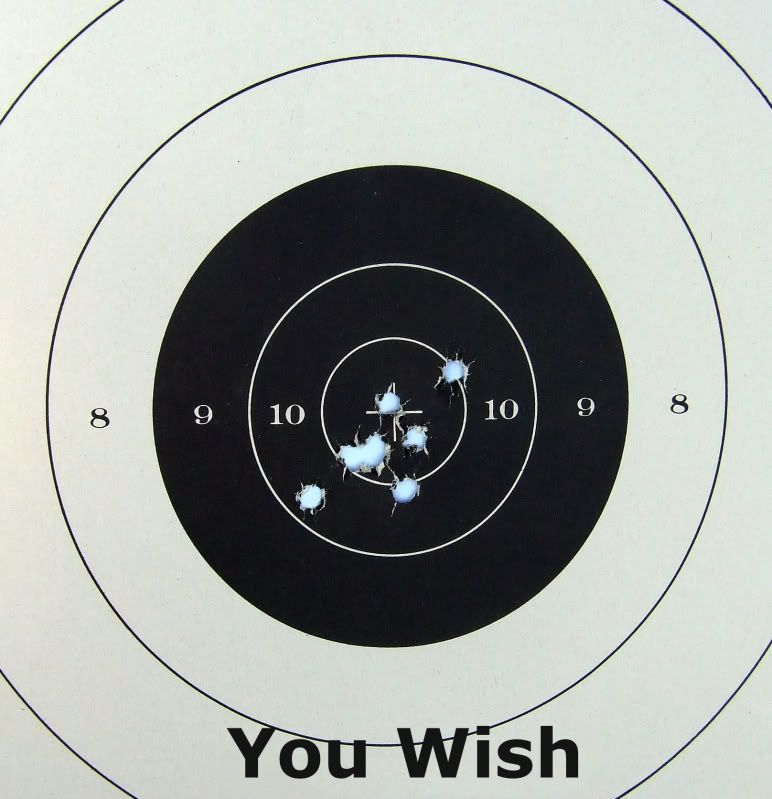

For my next tricks I am going to load up some 270SAA with lube cookie and chrono those, and I want to coem up with a BP load for a 230gr bullet that chronos 750-800fps muzzle so I can shoot steel target with the 1911 owners.

For the former I need ambients above +20dF so my chrnograph will run, for the latter I am probably going to need some cloth wads and some cream of wheat and maybe a compressor step too.