So a couple weeks ago, I purchased and received 500 X-treme 200gn FP's (plated, of course) for 45 ACP. These bullets are new to me so I needed to determine the OAL. Well frankly, I was too lazy to dismantle my 1911's (3) to do the plunk tests. And I have the OAL recommendations for the entire line of Berry's bullets. I was thinking how different can their ogive's be from X-treme's?? Right? Wrong.

I loaded up 50 of them, OAL = 1.202 - I was shooting for 1.200 (Berry's recommendation); but I got 'em just a touch long (4.8gns TiteGroup, CCI 300, mixed brass) and took off to the range - with chronograph in tow.

About every third round, the gun (Kimber Target II) didn't quite want to go into battery. I had to force the slide forward a bunch of times. Then I got one that I couldn't get it into battery and it was a real beast to rack the slide back. I had a couple more of these. THEN - I had one that required extreme effort to rack it back, and when I finally did, I managed to pull the bullet apart. Powder everywhere; the bullet stuck in the breech.

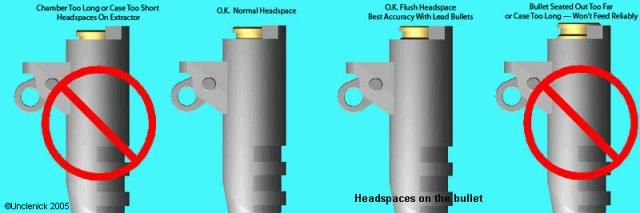

It was at that point when I figured I had an OAL problem .

.

(Background: I've had this gun only a few months, and our relationship has been a bit rocky - long stories. Point is, I was rather jumping to conclusions that it was just the Kimber giving me fits - again.)

After punching out the bullet with my trusty dowel, going in from the muzzle, I put on my strong glasses to aid my old eyes - and sure enough, extensive groove marks were clearly visible on the shoulder of the bullet. That left no doubt what the problem was.

When I got home, I decided to plunk test these bullets. Good idea, right?! In the Kimber, they plunked at 1.155 - a full 47 thousandths less than where I had them. And since I had my Colt handy (I took it to the range too. But I have completely different ammo for it, since it only has a 12 Lb recoil spring - it's my pure target shooter), I broke it down and plunked it too - 1.145 - 57 thousandths less (although I don't plan on using these bullets in the Colt).

In the Kimber, they plunked at 1.155 - a full 47 thousandths less than where I had them. And since I had my Colt handy (I took it to the range too. But I have completely different ammo for it, since it only has a 12 Lb recoil spring - it's my pure target shooter), I broke it down and plunked it too - 1.145 - 57 thousandths less (although I don't plan on using these bullets in the Colt).

I scrunched down the remaining ammo of the batch (27 rounds). Which I figure probably tore up the plating from the crimp. Therefore, I won't be using them for anything but range fodder now. As for the chronographing: I'll be retesting a new batch, with the new OAL - same charge weight. QuickLOAD shows only a modest boost in peak pressure.

So what's the moral to the story? Well, after 31 years of loading, it is still not wise to cut corners. I found myself in this situation out of pure laziness. I didn't feel like breaking down my guns to get to the barrels. I didn't feel like mocking up rounds, then pulling them when I was done, then reworking the brass, etc. - just pure laziness. No excuses. And I paid the price. I will be plunk testing all new semi-auto bullets from now on.

I loaded up 50 of them, OAL = 1.202 - I was shooting for 1.200 (Berry's recommendation); but I got 'em just a touch long (4.8gns TiteGroup, CCI 300, mixed brass) and took off to the range - with chronograph in tow.

About every third round, the gun (Kimber Target II) didn't quite want to go into battery. I had to force the slide forward a bunch of times. Then I got one that I couldn't get it into battery and it was a real beast to rack the slide back. I had a couple more of these. THEN - I had one that required extreme effort to rack it back, and when I finally did, I managed to pull the bullet apart. Powder everywhere; the bullet stuck in the breech.

It was at that point when I figured I had an OAL problem

(Background: I've had this gun only a few months, and our relationship has been a bit rocky - long stories. Point is, I was rather jumping to conclusions that it was just the Kimber giving me fits - again.)

After punching out the bullet with my trusty dowel, going in from the muzzle, I put on my strong glasses to aid my old eyes - and sure enough, extensive groove marks were clearly visible on the shoulder of the bullet. That left no doubt what the problem was.

When I got home, I decided to plunk test these bullets. Good idea, right?!

I scrunched down the remaining ammo of the batch (27 rounds). Which I figure probably tore up the plating from the crimp. Therefore, I won't be using them for anything but range fodder now. As for the chronographing: I'll be retesting a new batch, with the new OAL - same charge weight. QuickLOAD shows only a modest boost in peak pressure.

So what's the moral to the story? Well, after 31 years of loading, it is still not wise to cut corners. I found myself in this situation out of pure laziness. I didn't feel like breaking down my guns to get to the barrels. I didn't feel like mocking up rounds, then pulling them when I was done, then reworking the brass, etc. - just pure laziness. No excuses. And I paid the price. I will be plunk testing all new semi-auto bullets from now on.

Last edited: