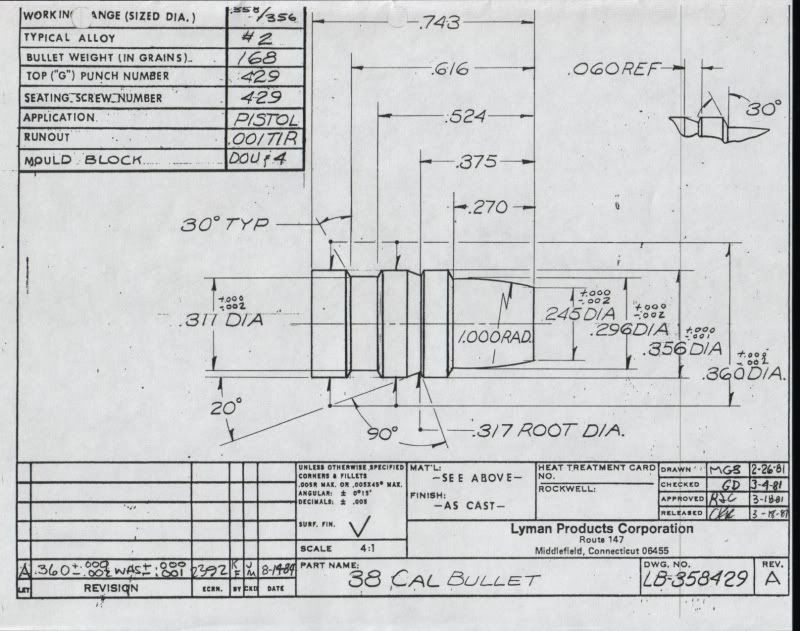

For quite a while I read `bout the length of the 358429 being toolong for the colts & smiths ,just could`nt comprehend it being too long for the GP100 ???

UNTIL I traded for a sc Lyman & noticed rite off the front band was wider , somewhat wider !!!

I trim my brass with the Lee system to 1,285" & with this boolit it only leaves .020" to the face of the cyl . Now I have no problem trimming the brass a bit to give it some breathing room , but was just amazed at the differences .

I`ve posted on this before but I now have my PC straightened out & can post a pic ,here it is .

UNTIL I traded for a sc Lyman & noticed rite off the front band was wider , somewhat wider !!!

I trim my brass with the Lee system to 1,285" & with this boolit it only leaves .020" to the face of the cyl . Now I have no problem trimming the brass a bit to give it some breathing room , but was just amazed at the differences .

I`ve posted on this before but I now have my PC straightened out & can post a pic ,here it is .