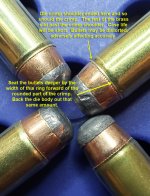

New Starline brass, Lee 3 die set, (no FCD, yet)

Left has 1/2-3/4 crimp, 5th round backing out .20 on my sp101

Right is additional crimp without additional seating and certainly doesn't look like the 44s I did long ago.

I have a Lee FCD & Redding profile crimp in my shopping cart but would like some guidance before I do anything.

Suggestions?

Left has 1/2-3/4 crimp, 5th round backing out .20 on my sp101

Right is additional crimp without additional seating and certainly doesn't look like the 44s I did long ago.

I have a Lee FCD & Redding profile crimp in my shopping cart but would like some guidance before I do anything.

Suggestions?