During the course of another thread, the thread drifted off and around the original thread topic, we all know how that can go. The original post went as follows:

Is this over pressure?by Gobsmack

Plenty of good stuff was covered and a portion of the thread wandered into case capacities and involved the practice of reducing loads when loading standard military GI brass. The theory behind this thinking is military brass is heavier and thicker so logically if the outside dimensions are all made the same the thicker brass should result in less case volume inside the case. All very logical and makes sense.

I decided a small science experiment (as my wife calls them) was in order. I began with the basics, collecting what I hoped would be a wide range of brass. All of the brass was once fired, commercial and military. I selected ten cases each of Remington Peters, Winchester, WCC 10, LC 13 and Federal. That makes for 5 manufacturers including two GI brass in the lot. Each case was sized using RCBS sizing dies and case head to shoulder datum was set for 1.630" using an RCBS Precision Mic which I tested with a Forrester 1.630 Go gauge the idea being I wanted equal case dimensions case to case, The cases were all trimmed to a 2.005" case OAL.

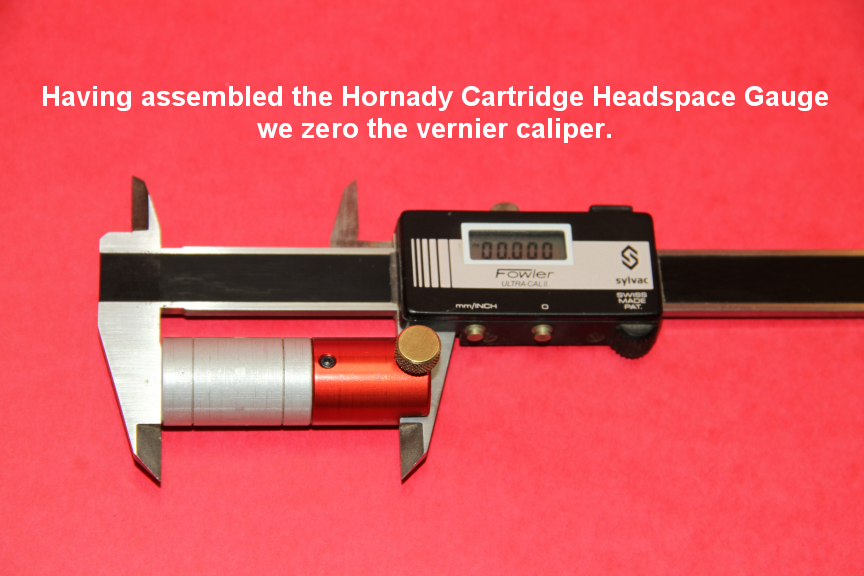

Next I weighed all 50 cases with clean primer holes, the case insides also had a spinning brush used on them. Following weight I used tiny measured 1.5 grain balls of modeling clay to fill the primer pockets and flash holes. I mixed a few drops of Dawn dish washing liquid into a gallon of pure distilled water at room temperature of 70 Degrees F. I used an injector syringe to fill each case and then weighed the cases with water and subtracted the 1.8 grain tare for the modeling clay.

So now I know how much water each case holds and I converted that to Volume expressed as cc (cubic Centimeters) Becomes obvious that retired people. for the most part, have a surplus of time.

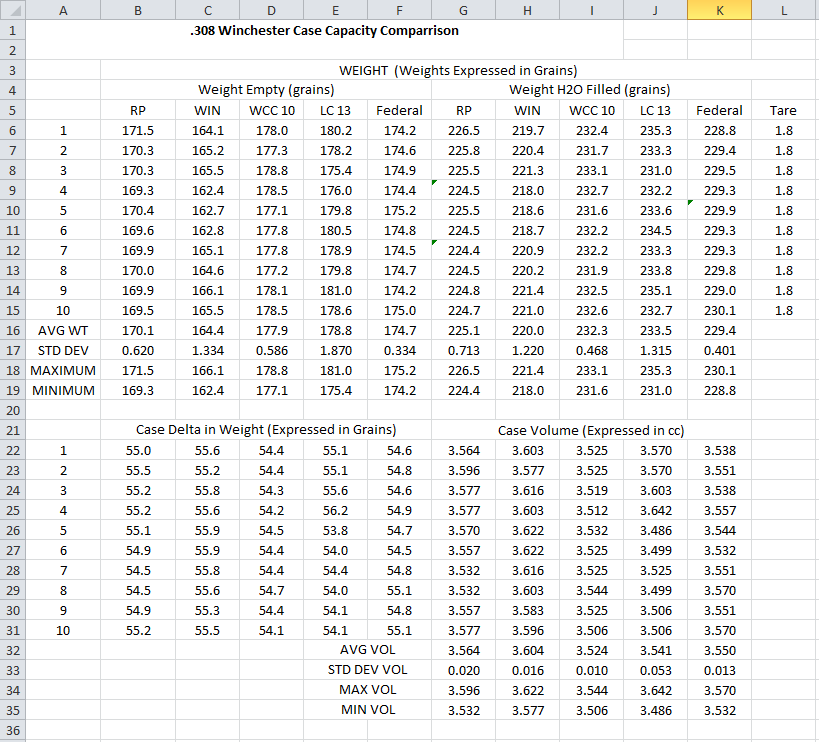

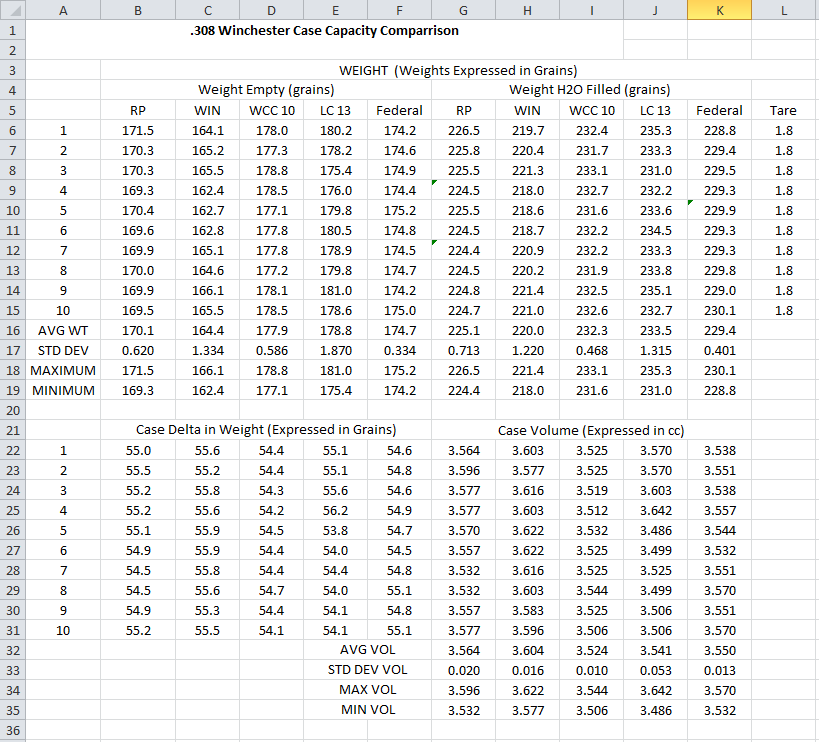

The cases were all dried and cleaned out. At this point my data sheet looks like this.

Looking at the numbers to date the RP Brass averaged 3.564 cc, the Winchester averaged 3.604 cc, the WCC 10 averaged 3.524 cc, the LC 13 averaged 3.541 cc and the Federal averaged 3.550 cc. So on average looking at the numbers the GI brass, the LC 10 and WCC 13 had lower averages than the three commercial manufacturer's brass. That being sort of expected. The nice number to look at though is The Standard Deviation number and this where small is good, like a golf score, the lower that standard deviation the more uniform the cases actually are and hand loaders should like that uniformity. This is where part 1 of my little science experiment ended for the year. So while the numbers change, how much will that volume metered change effect the powder charges and pressure?

This is where part 1 of my little science experiment ended for the year. So while the numbers change, how much will that volume metered change effect the powder charges and pressure?

My goal here is to prime each case with a CCI #200 large rifle primer and charge each case with 41 grains of AA 2495 powder under Sierra Match King 168 grain bullets using an RCBS micrometer bullet seater so all 50 bullets are seated uniform, or as close as I can get. Each 10 shot group will be run over an Oehler 35P Chronograph. I also hope to instrument the gun with a strain gauge pressure sensor so I can record the pressure curves. Granted I will not capture dead accurate pressures but I am more interested in just plotting curves for each shot. The latter will take some work but it should be a warm nice summer. I will also record the ammunition temperatures. This is more about curiosity than much else. Looking at the numbers in the spread sheet how much difference will those case volumes change for a given load and bullet weight> Rhe real question becomes will it matter enough the change velocity 15 feet downrange of the muzzle? Will it change things to actuallt see a pressure curve change? How much, in this scnario, will it matter?

I am very open to any thoughts or ideas.

Ron

Is this over pressure?by Gobsmack

I fired a number of the following rounds of .308 and saw some cratering. Does it look like a problem? Details as follows: LC03 and LC05 brass trimmed to 2.005", headspaced to 1.625", CCI 34 primers, Hornady 168gr. BTHP, 41.6gr. of IMG4895. Hornady says 41.4 is max but QL says 44.9 is max and I see a ton of people using this 42-43 grains online. I actually went to 41.6 because I originally confused the H4895 and IMR4895 numbers BUT, QL insists that 41.6 should be fine.

Fired out of a Polytech M14S with a professionally and recently installed LRB bolt.

Plenty of good stuff was covered and a portion of the thread wandered into case capacities and involved the practice of reducing loads when loading standard military GI brass. The theory behind this thinking is military brass is heavier and thicker so logically if the outside dimensions are all made the same the thicker brass should result in less case volume inside the case. All very logical and makes sense.

I decided a small science experiment (as my wife calls them) was in order. I began with the basics, collecting what I hoped would be a wide range of brass. All of the brass was once fired, commercial and military. I selected ten cases each of Remington Peters, Winchester, WCC 10, LC 13 and Federal. That makes for 5 manufacturers including two GI brass in the lot. Each case was sized using RCBS sizing dies and case head to shoulder datum was set for 1.630" using an RCBS Precision Mic which I tested with a Forrester 1.630 Go gauge the idea being I wanted equal case dimensions case to case, The cases were all trimmed to a 2.005" case OAL.

Next I weighed all 50 cases with clean primer holes, the case insides also had a spinning brush used on them. Following weight I used tiny measured 1.5 grain balls of modeling clay to fill the primer pockets and flash holes. I mixed a few drops of Dawn dish washing liquid into a gallon of pure distilled water at room temperature of 70 Degrees F. I used an injector syringe to fill each case and then weighed the cases with water and subtracted the 1.8 grain tare for the modeling clay.

So now I know how much water each case holds and I converted that to Volume expressed as cc (cubic Centimeters) Becomes obvious that retired people. for the most part, have a surplus of time.

The cases were all dried and cleaned out. At this point my data sheet looks like this.

Looking at the numbers to date the RP Brass averaged 3.564 cc, the Winchester averaged 3.604 cc, the WCC 10 averaged 3.524 cc, the LC 13 averaged 3.541 cc and the Federal averaged 3.550 cc. So on average looking at the numbers the GI brass, the LC 10 and WCC 13 had lower averages than the three commercial manufacturer's brass. That being sort of expected. The nice number to look at though is The Standard Deviation number and this where small is good, like a golf score, the lower that standard deviation the more uniform the cases actually are and hand loaders should like that uniformity.

My goal here is to prime each case with a CCI #200 large rifle primer and charge each case with 41 grains of AA 2495 powder under Sierra Match King 168 grain bullets using an RCBS micrometer bullet seater so all 50 bullets are seated uniform, or as close as I can get. Each 10 shot group will be run over an Oehler 35P Chronograph. I also hope to instrument the gun with a strain gauge pressure sensor so I can record the pressure curves. Granted I will not capture dead accurate pressures but I am more interested in just plotting curves for each shot. The latter will take some work but it should be a warm nice summer. I will also record the ammunition temperatures. This is more about curiosity than much else. Looking at the numbers in the spread sheet how much difference will those case volumes change for a given load and bullet weight> Rhe real question becomes will it matter enough the change velocity 15 feet downrange of the muzzle? Will it change things to actuallt see a pressure curve change? How much, in this scnario, will it matter?

I am very open to any thoughts or ideas.

Ron

![B]](http://[B][I][U][url]http://www.bearblain.com/images/CG4.png[/url][/U][/I][/B])