Scottish Highlander

New member

Evening all, long time since I have posted on here. I have been reloading quite some time now and was always using once fired Sako brass in my rifle that was fire formed to my rifle. I recently bought 140 Lapua brass once fired from a source. I trimmed all the brass and it had already been necked through a die and tumbled.

I primed and loaded with powder but now that I've done that I went to fire the brass and the bolt is very stiff on closing on some of it. Not all of it!

The brass is the correct length which is 100% definite.

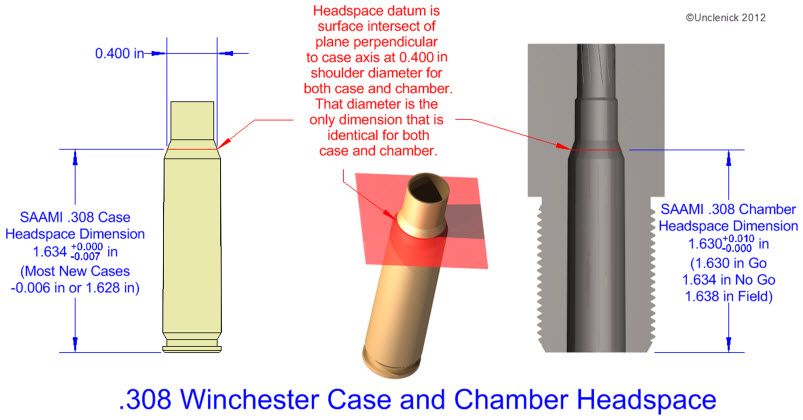

The bullets COAL are all withing parameters with the bullet seated so it is .040 back from the lands. Obviously the only problem left is the shoulder of the brass is hitting the rifling as I shut the bolt which is making it stiff to close.

My question is are these safe to fire and once fired will they fire form to my chamber or will they still be stiff to close. I don't have a full length die but might need to buy one to bump the shoulder back a thou or two so the bolt closes smooth.

What is your technical opinion everyone ?

Thanks all the way from Scotland

I primed and loaded with powder but now that I've done that I went to fire the brass and the bolt is very stiff on closing on some of it. Not all of it!

The brass is the correct length which is 100% definite.

The bullets COAL are all withing parameters with the bullet seated so it is .040 back from the lands. Obviously the only problem left is the shoulder of the brass is hitting the rifling as I shut the bolt which is making it stiff to close.

My question is are these safe to fire and once fired will they fire form to my chamber or will they still be stiff to close. I don't have a full length die but might need to buy one to bump the shoulder back a thou or two so the bolt closes smooth.

What is your technical opinion everyone ?

Thanks all the way from Scotland