I'm not sure of the actual discussion you saw, but I also had the conversation on another forum and it referenced this video:

https://www.youtube.com/watch?v=MOZpy55U-jY

SAAMI max for .22LR is quite low, some 24k PSI max or somewhere near there, isn't it? Compare that to modern... or better, I should say... popular calibers and it falls short. A good reason for that is the age of the chambering itself, always have to be wary of very OLD guns that are chambered for the same thing. Another good reason is the construction of the brass cartridge case, the rimfire style of priming makes for a folded case head that is inherently less able to resist higher pressures.

So I'm curious about the pressures at work in these blank cartridges...

or maybe I should say, where these are

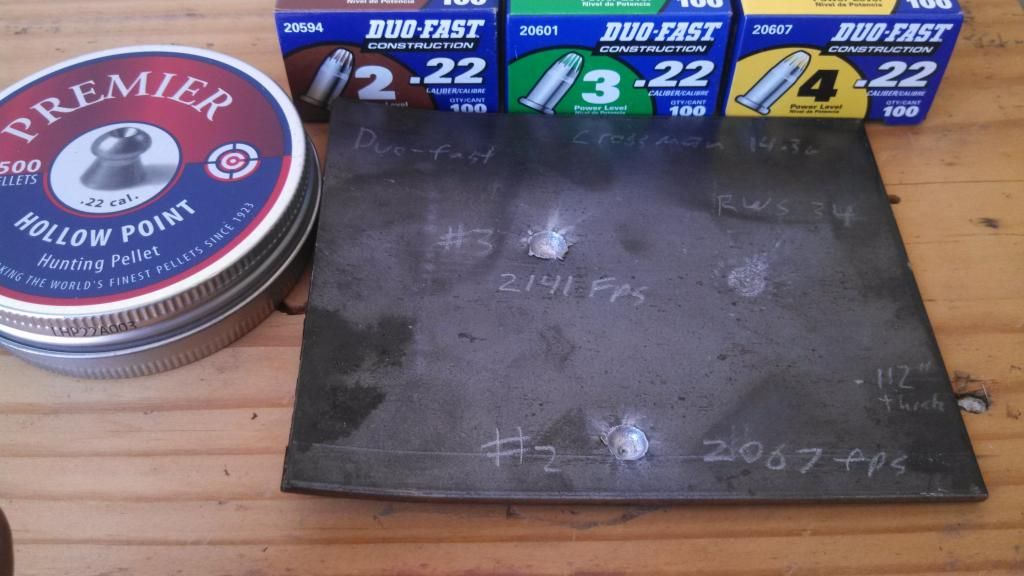

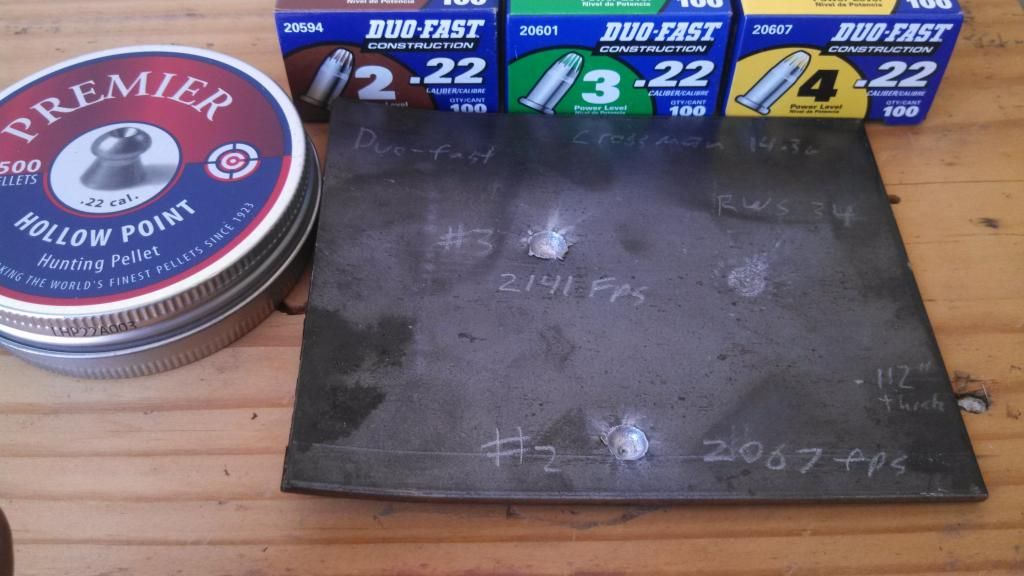

designed to operate. For whatever it is they do when they are discharged, a large part of the equation is whatever is resisting the blast. In the case of their actual design, it's going to be some sort of industrial nail or brad. In the case of these guys and their testing, it's a lead pellet of known weight.

When you take these little blank rounds and you put an obstruction in front of them that is -NOT- what they were designed to do, you are altering the max chamber pressure of their design... which I can't say we even know from the get-go. Off hand, I can't even guess if a 14 grain pellet is lighter or heavier than

whatever the nail or brad is that's meant to be used in the industrial application for which they were intended.

In this day and age, gun manufacturers can certainly make chambers and barrels that can handle a .22LR round that were upped from 24k PSI but the question becomes... can the cartridge case withstand it? Can the unlocked breech/blowback design handle it? And how long before someone slips a hot .22LR in to a 100-year old platform of some sort?

We know this from conventional centerfire handloading: if we take a known full-pressure cartridge and we knock more than HALF the bullet weight off it, we know that we'll need to increase the powder charge to bring the round up to pressure spec. And that's if we can find a bullet that will fit. (because we don't typically see that wide a range in one bullet diameter.) In fact if we did... we would most likely also change powders entirely to address the radically different bullet weight.

I think all of that adds up to the possibility that these nail gun blanks were built & designed specifically to run at a higher pressure than .22LR ammunition, and that's why these pellets are hitting like hammers compared to ammo from the same exact firearms.

So, who else thinks this is a really dumb thing to do?

I find it interesting far more so than "dumb." Depending on the

HOW and

WHERE, it's just testing and experimenting. If it's not your cup of tea,

you probably shouldn't take part in it. And it does kind of sound like it isn't your cup of tea.

Back to the subject:

if the pellets placed in front of these blanks are

less in weight than the actual nails or brads used in the tools for which these are designed...

then all the OP actually did was run them at

less pressure than the blanks were designed. But in all likelihood, he ran them at a pressure over spec for the rifle itself. Without knowing more, we don't know.