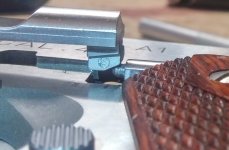

What is the distance the slide stop plunger is supposed to protrude from the plunger tube with no slide stop in place? Measured from the end of the plunger tube to the tip of the spherical radius on the end of the slide stop plunger at rest.

The reason I'm asking is because mine protrudes far enough that the spherical radius on the end is well past the ramped surface on the slide stop preventing it from depressing the plunger during assembly, the only way is to use a tool to manually depress the plunger into the frame a bit.

The reason I'm asking is because mine protrudes far enough that the spherical radius on the end is well past the ramped surface on the slide stop preventing it from depressing the plunger during assembly, the only way is to use a tool to manually depress the plunger into the frame a bit.