You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

17HMR Marlin

- Thread starter stagpanther

- Start date

stagpanther

New member

The marlin has a strange 1/2 pillar of sorts that dovetails into the barrel but does not extend all the way to the bottom metal. There is no rear pillar at all. I decided I will go ahead and fully pillar and bed, even if the stresses are negligible. Trigger is another issue, mine breaks at a rather hefty 4.25 lbs, gotta do something about that.

stagpanther

New member

I got the pillar in for the front screw by widening the hole in the stock the length of where it meets the dovetailed pillar that Marlin puts on the barrel. Can't say for sure whether or not that makes an inherent stress point. Also put a pillar in for the rear screw. I can tell by the "mushiness" feeling (wood is compressing someplace) when tightening the screws and movement of the barrel relative to the stock something is off and creating asymmetry in the seating. I ordered a marlin trigger guard from Brownells--what I got was for a Remington 700. They may be the same in almost all respects--but screw head countersink wasn't the same and rather than get into a return song-and-dance I drilled the hole out a bit, a bit tricky since the screw can easily bind the bolt if screwed in too far.

Last edited:

stagpanther

New member

Finished the work for now, probably didn't need it but I did some bedding in the front and back--a bigger issue is that I had to look around for stress points since that was definitely causing asymmetry in the seating. For example, where it appears the barrel is pinned to the receiver the stock is not inletted where the pin sticks out on the sides--creating a rockering stress point in the bedding. I also popped on a new vortex diamondback tactical ffp with ebr reticle--works great with is IMO. Also used a harris bipod. Did my shooting today at 178 yds in the blazing heat, unfortunately the barrel got blazing hot just sitting in the sun so I only shot 4 groups before I called it quits.

Here is hornady's 17 vmax:

and CCI's 17VNT which I'm guess is the same thing with different make-up.

I can't say for sure if all the work made a significant improvement in the rifle, my gut feeling is that maybe a better variety of higher quality ammo might help.

Here is hornady's 17 vmax:

and CCI's 17VNT which I'm guess is the same thing with different make-up.

I can't say for sure if all the work made a significant improvement in the rifle, my gut feeling is that maybe a better variety of higher quality ammo might help.

Attachments

stagpanther

New member

The hornady ammo comes with a warning on the box : "WARNING: range 2 miles, 3 kilometers"

????

????

stagpanther

New member

A little work on the trigger and I got it breaking at about 16 oz's now (stock was 4.25 lbs) --that will hopefully help some.

stagpanther

New member

Tried again today but conditions were actually a little worse, stronger winds and just as hot, so I gave up after 5 groups. Most of the stuff shot around 1.2 MOA at 187 yds The CCI VNT seems to be the best overall. I'm a bit mystified why 17 hmr does so well up to 100 yds but seems to "lose it" shortly thereafter even though it's still cooking along supersonic.

Attachments

44caliberkid

New member

My brother gave me his 917 to sell, it's just stock, as it came, with a BSA 4X scope calibrated for 17HMR. It's a horrible scope, dim, blurry, yellow green cast to the light it lets in. The elevation calibrations for 17 HMR are right on though. I'm getting sub 1/2 inch groups at 100 yards with Hornady 17 grain Varmint . I'd keep it but I'm trying to reduce my own collection too.

stagpanther

New member

100yds in it does extremely well, I'm just a bit stumped why it loses that accuracy so quickly as it goes past that while still retaining supersonic velocity. I've seen no signs of destabilization out to two hundred yards and beyond.

44caliberkid

New member

Ok, I just noticed your target distance.

stagpanther

New member

Today I went out to try an order of hornady 17 hmr ammo that just came in, they all shot pretty well except for the 15.5 gr stuff which for some unknown reason wouldn't stabilize and sprayed erratically on the target. I shot 7round groups since that's what fits in the magazine. I also moved in to 100 yds thinking that might help with reducing mirage and the effects of the gusty winds--it is blowing pretty good today but remains very hot.

Except for the 15.5 gr bullets, the first 4 groups hovered right around MOA which I was content with.

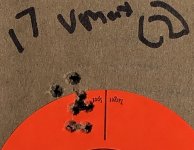

I shot my last group with the barrel blazing hot and little time between each shot, expecting mediocre results and instead got this (around .6 moa):

It doesn't make sense to me things would improve for those reasons, so I guess I just got lucky.

This rimfire stuff is still a bit mysterious to me.

Except for the 15.5 gr bullets, the first 4 groups hovered right around MOA which I was content with.

I shot my last group with the barrel blazing hot and little time between each shot, expecting mediocre results and instead got this (around .6 moa):

It doesn't make sense to me things would improve for those reasons, so I guess I just got lucky.

This rimfire stuff is still a bit mysterious to me.

Attachments

Stag- I didn't see where you mentioned it, but have you played with the stock bolt's torque? Until this year, I never considered putting my Lyman torque screwdriver to work on a rimfire, but holy cow, what a difference finding the sweet spot makes!

And speaking of finding the right torque value for wood/laminate stocks- does anyone know if the amount of needed torque increases or decreases over time/years? I know the wood is pretty dry by the time it becomes a stock and is sealed pretty well when it's a laminate. But, lets say I buy a rifle from somewhere soggy (humid) like Louisiana. If I put 26 inch/lbs on it when it gets to the TX Panhandle (dry)- will those 26 in/lbs still be good a year or two from now as the wood dries, or 10 years from now as the wood ages?

And speaking of finding the right torque value for wood/laminate stocks- does anyone know if the amount of needed torque increases or decreases over time/years? I know the wood is pretty dry by the time it becomes a stock and is sealed pretty well when it's a laminate. But, lets say I buy a rifle from somewhere soggy (humid) like Louisiana. If I put 26 inch/lbs on it when it gets to the TX Panhandle (dry)- will those 26 in/lbs still be good a year or two from now as the wood dries, or 10 years from now as the wood ages?

stagpanther

New member

My low recoil rimfire probably doesn't need much in the way of torque would be my guess, the marlin I have actually has the front bolt ride into a socket which is dovetailed directly to the barrel in front of the receiver (!). the rear bolt goes into a very narrow space between the trigger and magazine catch. The stocks I did recently for 300 win mag and 300 Weatherby mag are a different story. I'm not an expert by any stretch in pillar and bedding stocks--but what I have noticed is that in general the fewer stress points there are in the bedding, usually the less torque I need to get a solid seat for the receiver. I try to get a continuous steel pillar from the bottom metal to the receiver and make the adjoining areas devconned with plastic steel, theoretically allowing for some degree of expansion and contraction in the wood. I would very much like to hear from someone with more experience what their opinion is.

Almost every single used wood stock I've ever looked at has, over time, been over-torqued compressing the wood adjacent to the bolt holes, sometimes even cracking the stock (with the exception of those full-pillared right from the start).

Almost every single used wood stock I've ever looked at has, over time, been over-torqued compressing the wood adjacent to the bolt holes, sometimes even cracking the stock (with the exception of those full-pillared right from the start).

Last edited: